A kind of polymeric ferric acetate and its preparation method and application

A technology of iron acetate and glacial acetic acid, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water/sludge/sewage treatment, etc., can solve concrete structure corrosion, steel structure corrosion, chloride ion pollution, etc. problems, to achieve the effect of improved flocculation performance, low production cost, and neutralization of strong electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] At room temperature (15-25°C), dissolve ferrous sulfate or ferrous sulfate heptahydrate in water to obtain a ferrous sulfate solution, in which the concentration of ferrous ions is 1.80mol / L; add glacial acetic acid and potassium chlorate in sequence during continuous stirring Mix evenly to obtain a mixed solution, in which the molar ratio of ferrous ions to acetic acid is 1:4.0, and the molar ratio of ferric ions to potassium chlorate is 5.6:1; then placed in a constant temperature water bath at 60°C for 6 hours to remove impurity ions to obtain The reddish-brown liquid product is polymerized ferric acetate.

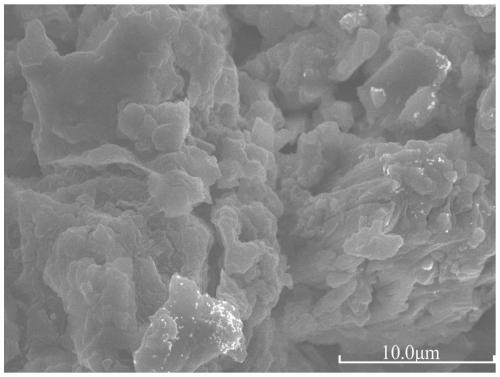

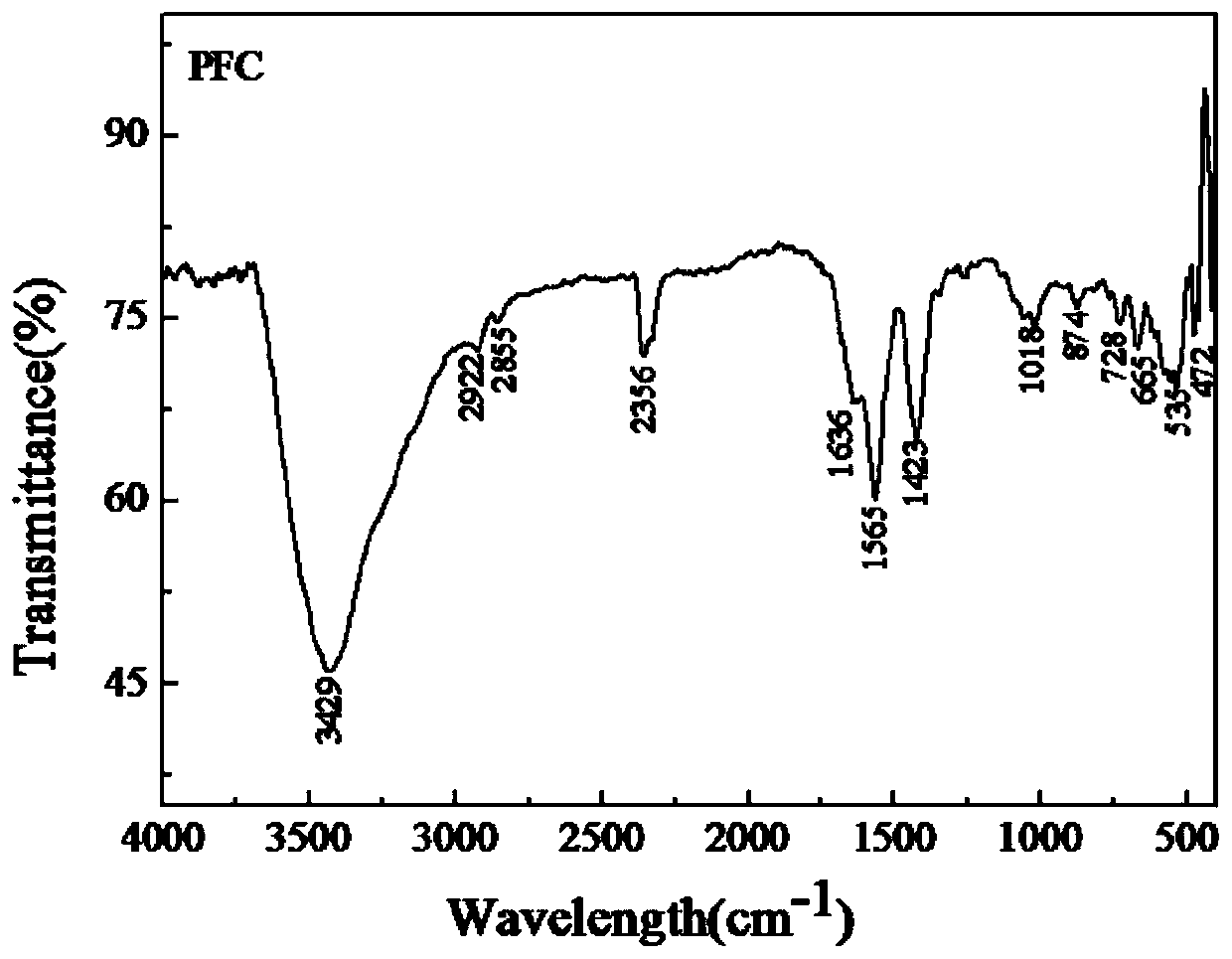

[0026] The liquid product obtained in Example 1 was dried at 50° C., and the morphology characteristics of the obtained sample were analyzed using a model SU1510 scanning electron microscope (SEM) and a Shimadzu Nicolet-380 Fourier transform infrared spectrometer.

[0027] figure 1 It is the SEM photo of the polymerized iron acetate obtained in Example 1. It can...

Embodiment 2

[0031] At room temperature (15-25°C), dissolve ferrous sulfate or ferrous sulfate heptahydrate in water to obtain a ferrous sulfate solution, in which the concentration of ferrous ions is 1.90mol / L; add glacial acetic acid and potassium chlorate in sequence during continuous stirring Mix evenly to obtain a mixed solution, in which the molar ratio of ferrous ions to acetic acid is 1:4.0, and the molar ratio of ferric ions to potassium chlorate is 5.5:1; then placed in a constant temperature water bath at 50°C for 6 hours to remove impurity ions to obtain The reddish-brown liquid product is polymerized ferric acetate.

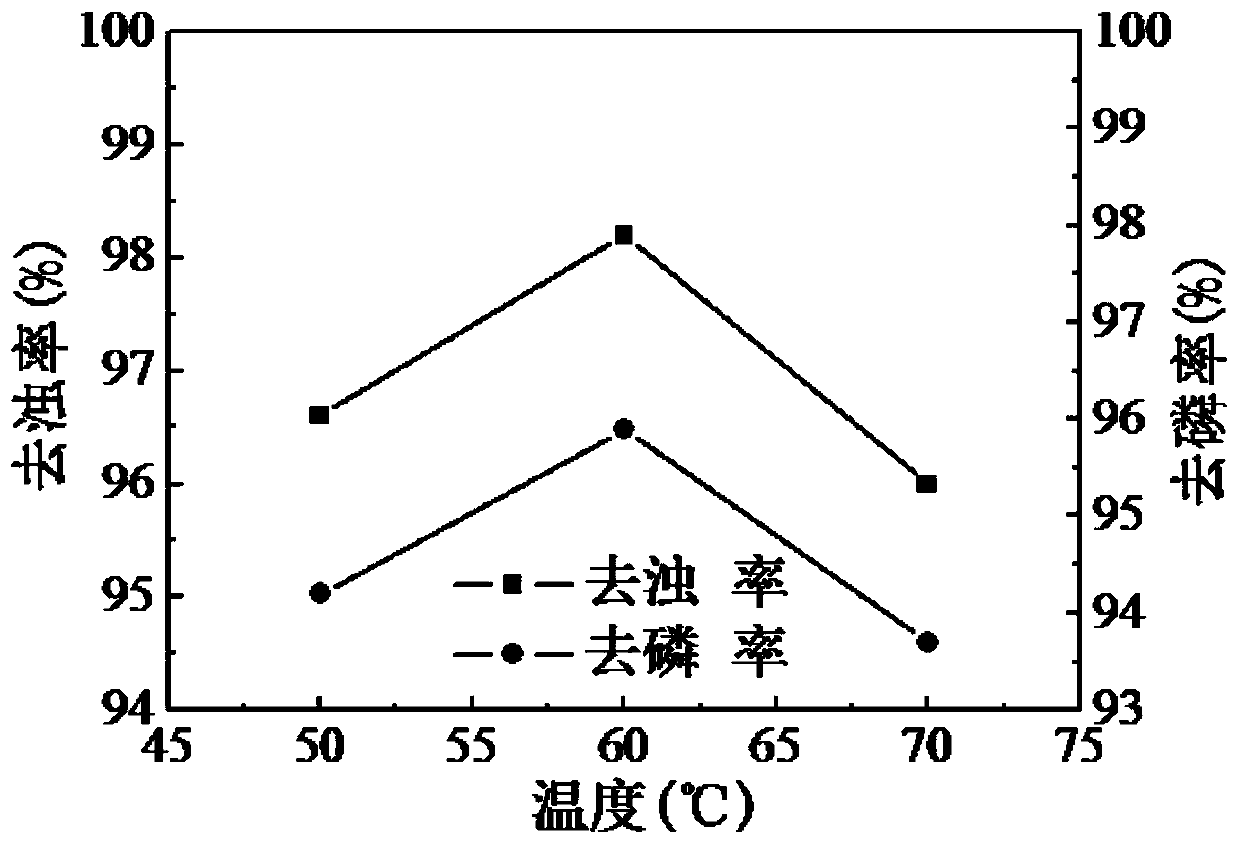

[0032] The above-mentioned polymerized ferric acetate is used to treat wastewater with a phosphorus concentration of 6mg / L, the pH of the wastewater is 7.76, the amount of flocculant is 24mg / L, and it is stirred rapidly at 250r / min for 2min, and then stirred at a slow speed of 60r / min for 15min. Settled for 20min. Its turbidity removal rate is 96.6%, and phospho...

Embodiment 3

[0034] At room temperature (15-25°C), dissolve ferrous sulfate or ferrous sulfate heptahydrate in water to obtain a ferrous sulfate solution, in which the concentration of ferrous ions is 1.85mol / L; add glacial acetic acid and potassium chlorate in sequence during continuous stirring Mix evenly to obtain a mixed solution, in which the molar ratio of ferrous ions to acetic acid is 1:4.0, and the molar ratio of ferric ions to potassium chlorate is 5.55:1; then placed in a constant temperature water bath at 70°C for 6 hours to remove impurity ions to obtain The reddish-brown liquid product is polymerized ferric acetate.

[0035] The above-mentioned polymerized ferric acetate is used to treat wastewater with a phosphorus concentration of 6mg / L, the pH of the wastewater is 7.76, the amount of flocculant is 24mg / L, and it is stirred rapidly at 250r / min for 2min, and then stirred at a slow speed of 60r / min for 15min. Settled for 20min. Its turbidity removal rate is 96%, and phosphor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com