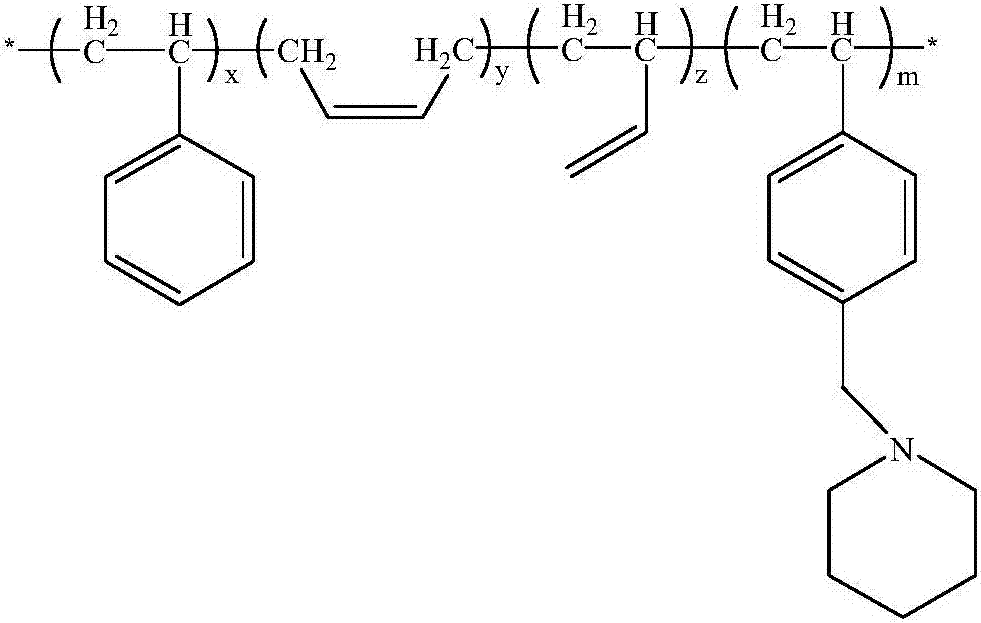

Amino-functionalized solution polymerized styrene-butadiene copolymer and preparation method thereof

A technology of amine-based functional copolymers, applied in rolling resistance optimization, transportation and packaging, special tires, etc., can solve the problems of long preparation time of copolymers, low actual content of functional groups, limited industrialization potential, etc., and achieve good industrialization development Potential, preparation method is simple and easy, the effect of good industrial adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

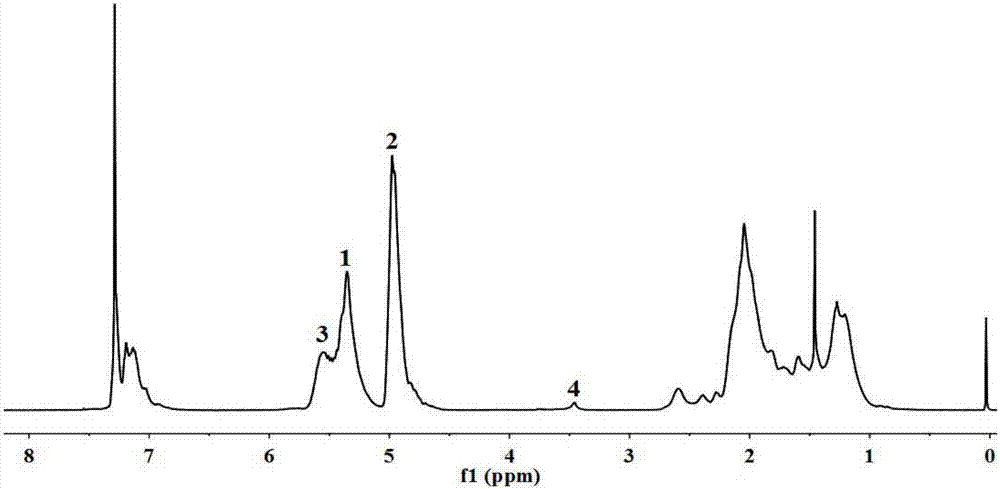

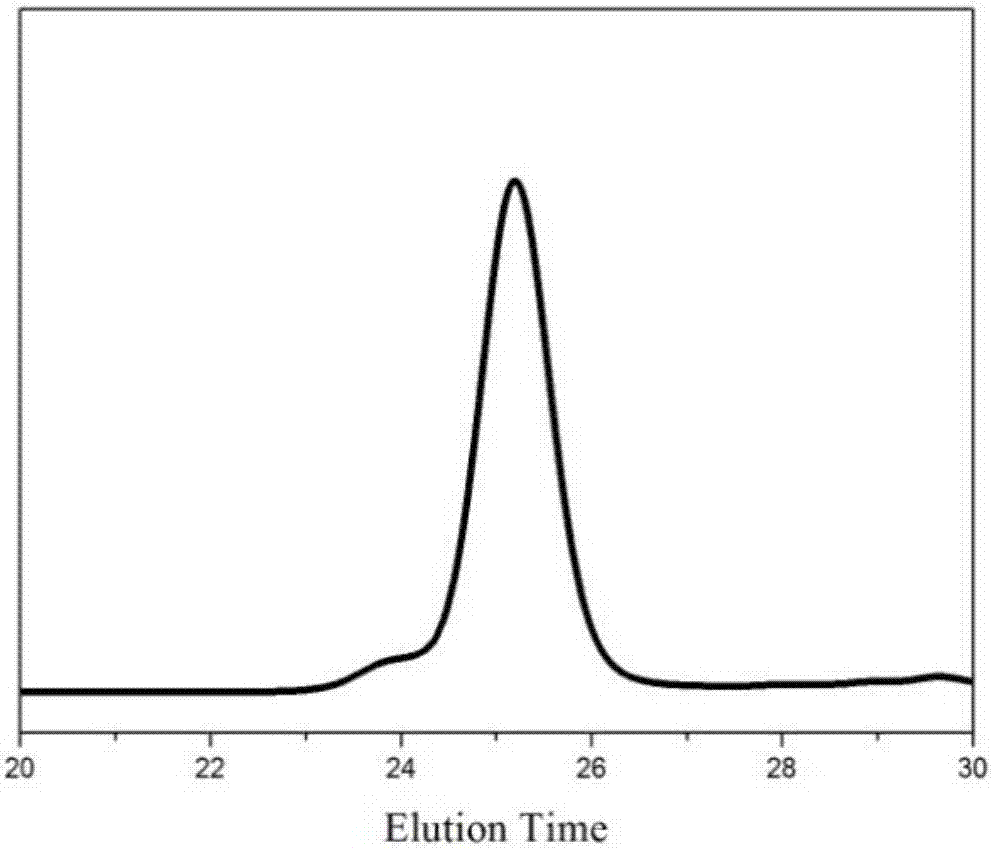

Embodiment 1

[0031] Preparation of random copolymer of 4-(piperidinylmethyl)styrene and butadiene. Take a clean 100mL double-branch three-neck polymerization bottle, and repeat the extraction-gas lamp baking-nitrogen filling treatment three times, and then add 0.9g 4-(piperidinylmethyl)styrene monomer and 30ml butadiene to it in sequence Hexane solution (concentration of 7g / 100ml), 0.16ml N,N-dimethyltetrahydrofurfurylamine in cyclohexane solution (concentration of 0.5mol / L), stir evenly, heat up to 50℃, add 0.3 0.33ml of mol / L n-Buli initiator, react for 3h. After the polymerization is completed, the reaction is terminated with ethanol, and then a large amount of industrial alcohol is used to precipitate the polymer, which is dried in a vacuum oven to obtain a 4-(piperidylmethyl)styrene-butadiene random copolymer. The measured conversion rate was 100%, Mn=30900, MWD=1.08.

Embodiment 2

[0033] Preparation of 4-(piperidinylmethyl)styrene and styrene random polymer. Take a clean 100mL double-branch three-neck polymerization bottle, and repeat the extraction-gas lamp baking-nitrogen filling treatment three times, and then add 30ml cyclohexane and 0.9g 4-(piperidylmethyl)styrene monomer to it in turn , 2.1g styrene, 0.16ml N,N-dimethyltetrahydrofurfurylamine in cyclohexane solution (concentration 0.5mol / L), stir evenly, heat up to 50℃, add 0.3mol / L n-Buli 0.33ml initiator, react for 3h. After the polymerization is completed, the reaction is terminated with ethanol, and then a large amount of ethanol is used to precipitate the polymer, which is dried in a vacuum oven to obtain a 4-(piperidylmethyl)styrene-styrene random copolymer. The measured conversion rate was 100%, Mn=31000, MWD=1.10.

Embodiment 3

[0035] Preparation of ternary random copolymer of 4-(piperidylmethyl)styrene, styrene and butadiene. Take a clean 100mL double-branch three-neck polymerization bottle, and repeat the extraction-gas lamp baking-nitrogen filling treatment three times, and then add 0.5g 4-(piperidylmethyl)styrene monomer and 0.4g benzene to it in sequence Ethylene, 30ml butadiene in cyclohexane solution (concentration of 7g / 100ml), 0.16ml of tetrahydrofurfuryl alcohol ethyl ether in cyclohexane solution (concentration of 0.5mol / L), stir evenly, warm up to 50℃, add 0.33ml of 0.3mol / L n-Buli initiator was reacted for 3h. After the polymerization, the reaction is terminated with ethanol, and then a large amount of ethanol is used to precipitate the polymer, which is dried in a vacuum oven to obtain a 4-(piperidylmethyl)styrene-styrene-butadiene ternary random copolymer. The measured conversion rate was 100%, Mn=32000, MWD=1.11.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com