Polymer hybrid grafted nano silica and PVDF microfiltration membrane and its application

A nano-silica, silica technology, applied in chemical instruments and methods, ultrafiltration, membrane technology, etc., can solve the problems of membrane pollution, unfavorable practical application, etc., achieve simple modification process, enhance surface wetting characteristics, The effect of high-efficiency oil-water separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

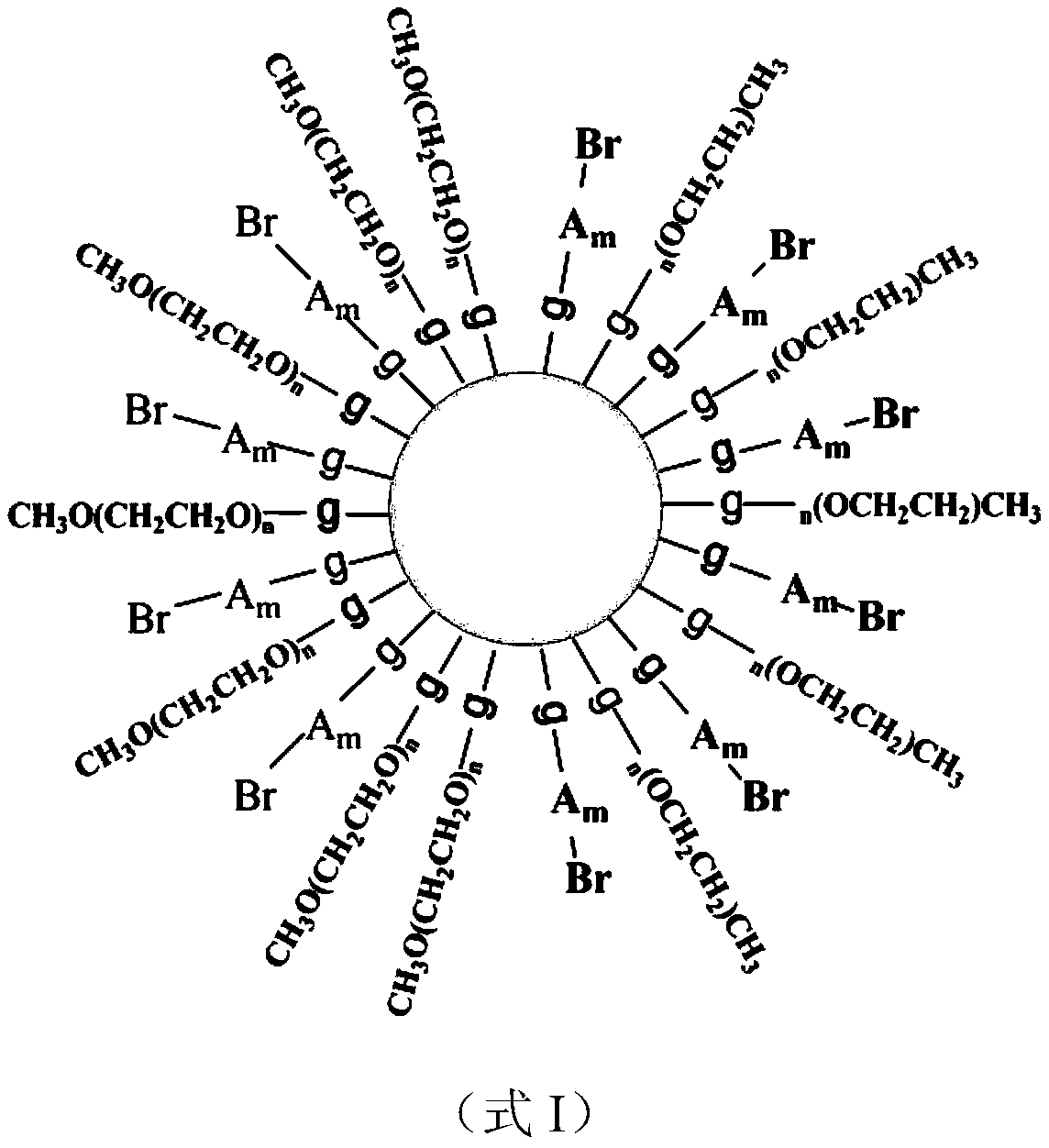

[0067] A polymer hybrid grafted nano silica, prepared by the following method:

[0068] (1) Disperse 20g of silica with a particle size of 90nm in 500ml of anhydrous toluene, add 100g of aminopropyltriethoxysilane, fill with nitrogen and heat to boiling, then reflux at a constant temperature (105°C) for 48h, and then sequentially Wash with anhydrous toluene, anhydrous acetone, and vacuum dry to obtain aminated silica;

[0069] (2) Disperse 20 g of surface aminated silica in 500 ml of anhydrous xylene, add 15 g of triethylamine, and drop 5 g of 2-bromoisobutyryl bromide in an ice-water bath. Cancel the ice-water bath, let the system naturally heat up to 25°C for 4h, then wash the product with methanol precipitation and vacuum dry to obtain brominated silica;

[0070] (3) Disperse 20 g of brominated silica in 500 ml of N,N-dimethylformamide solution, add 2 g of sodium azide, and stir at 20-30°C for 24 hours. The product is precipitated, washed, and dried in vacuum to obtain silica az...

Embodiment 2

[0079] A polymer hybrid grafted nano silica, prepared by the following method:

[0080] (1) Disperse 20g of silica with a particle size of 250nm in 500ml of anhydrous toluene, add 100g of aminopropyltriethoxysilane, fill with nitrogen and heat to boiling, then reflux at a constant temperature (105°C) for 48h, and then sequentially Wash with anhydrous toluene, anhydrous acetone, and vacuum dry to obtain aminated silica;

[0081] (2) Disperse 20 g of aminated silica in 500 ml of anhydrous xylene, add 15 g of triethylamine, and drop 5 g of 2-bromoisobutyryl bromide in an ice-water bath. Cancel the ice-water bath, let the system naturally heat up to 25°C for 4h, then wash the product with methanol precipitation and vacuum dry to obtain brominated silica;

[0082] (3) Disperse 20 g of brominated silica in 500 ml of N,N-dimethylformamide solution, add 2 g of sodium azide, and stir for 24 hours at 20-30°C. The product is precipitated, washed, and dried in vacuum to obtain silica azide.

[...

Embodiment 3

[0090] A polymer hybrid grafted nano silica, prepared by the following method:

[0091] (1) Disperse 20g of silica with a particle size of 350nm in 500ml of anhydrous toluene, add 80g of aminopropyltriethoxysilane, fill with nitrogen and heat to boiling, then reflux at a constant temperature (105°C) for 48h, and then sequentially Wash with anhydrous toluene, anhydrous acetone, and vacuum dry to obtain aminated silica;

[0092] (2) Disperse 20 g of aminated silica in 500 ml of anhydrous xylene, add 10 g of triethylamine, and drop 3 g of 2-bromoisobutyryl bromide in an ice-water bath. Cancel the ice-water bath, let the system naturally heat up to 25°C for 4h, then wash the product with methanol precipitation and vacuum dry to obtain brominated silica;

[0093] (3) Disperse 20 g of brominated silica in 500 ml of N,N-dimethylformamide solution, add 2 g of sodium azide, and stir for 24 hours at 20-30°C. The product is precipitated, washed, and dried in vacuum to obtain silica azide.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com