High-thermal-conductivity photocureable coating for optical fiber and preparation method and application of high-thermal-conductivity photocureable coating

A light-curing coating and high thermal conductivity technology, applied in the direction of optical waveguide light guide, cladding optical fiber, polyester coating, etc., can solve the problems of low thermal conductivity of optical fiber coating, low thermal conductivity of coating, high thermal expansion coefficient, etc., to achieve enhanced Interface compatibility, good gloss, high hardness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

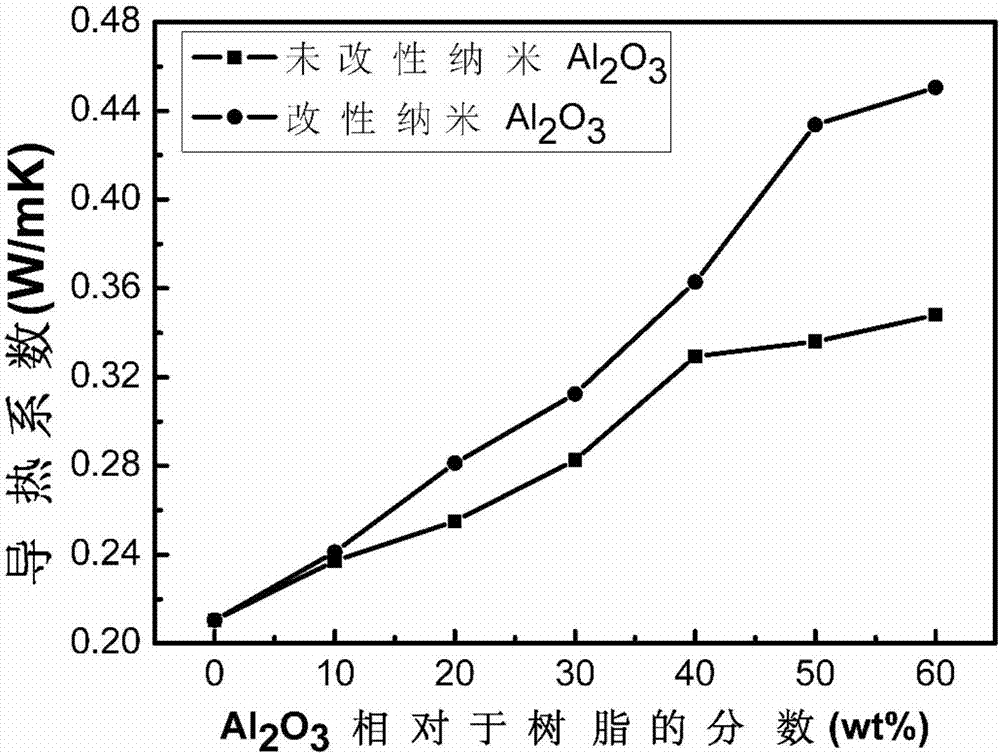

Embodiment 1

[0035] The high thermal conductivity light-curable coating for optical fiber in this embodiment includes acrylic resin, inorganic thermal conductive particles modified by vinyl silane coupling agent, reactive diluent, and photoinitiator. The acrylic resin is a bisphenol A epoxy acrylate resin; the inorganic thermally conductive particles modified by the vinyl silane coupling agent are vinyl triethoxy silane modified nano Al 2 O 3 The reactive diluent is glycidyl methacrylate, the addition ratio is 20wt% of bisphenol A epoxy acrylate resin; the photoinitiator is (2,4,6-trimethylbenzoyl) diphenyl Based on phosphine oxide, the addition ratio is 3wt% of bisphenol A epoxy acrylate resin.

[0036] The preparation method of the high thermal conductivity photocurable coating for optical fiber includes the following steps:

[0037] (1) Using vinyl triethoxy silane for nano Al 2 O 3 Process to prepare nano Al modified by vinyl triethoxy silane 2 O 3 :

[0038] In a 500mL round bottom flask, a...

Embodiment 2

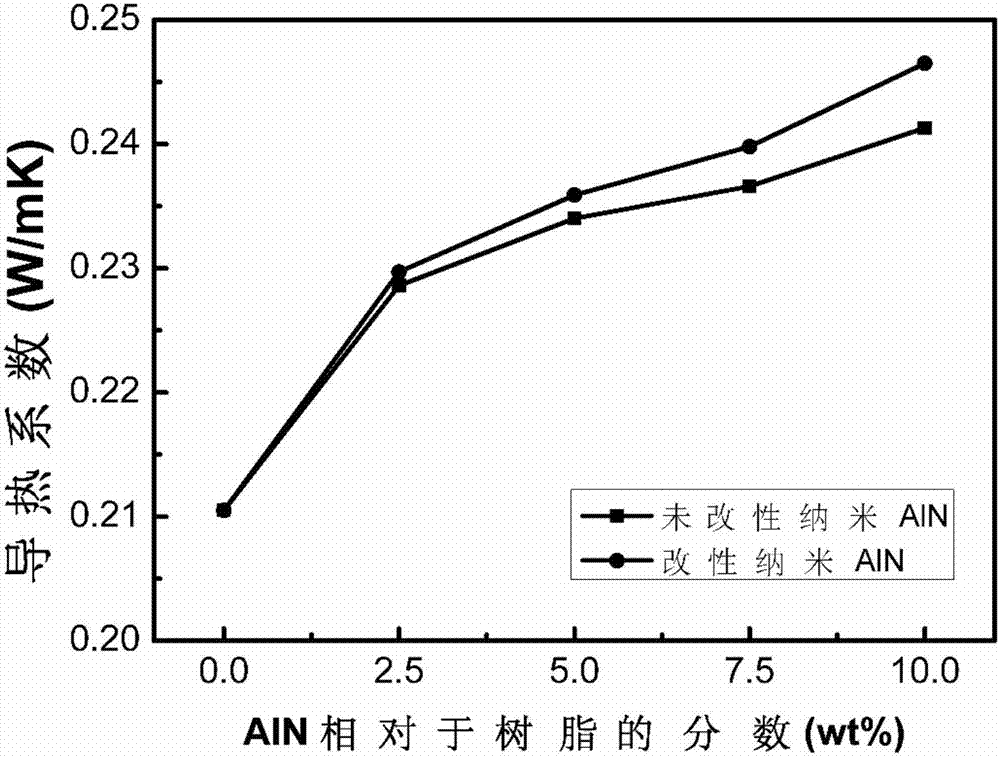

[0045] The high thermal conductivity photocurable coating for optical fiber in this embodiment includes acrylic resin, inorganic thermal conductive particles modified by vinyl silane coupling agent, reactive diluent, and photoinitiator. The acrylic resin is bisphenol A epoxy acrylate resin; the inorganic thermally conductive particles modified by the vinyl silane coupling agent are nano AlN modified by γ-methacryloxypropyltrimethoxysilane (Ie aluminum nitride); the reactive diluent is tripropylene glycol diacrylate, and the addition ratio is 20wt% of bisphenol A epoxy acrylate resin; the photoinitiator is 2,4,6-trimethyl Ethyl benzoylphenylphosphonate, the addition ratio is 3wt% of bisphenol A epoxy acrylate resin.

[0046] The preparation method of the high thermal conductivity photocurable coating for optical fiber includes the following steps:

[0047] (1) Use γ-methacryloxypropyltrimethoxysilane to treat nano AlN to prepare γ-methacryloxypropyltrimethoxysilane modified nano Al...

Embodiment 3

[0055] The high thermal conductivity photocurable coating for optical fiber in this embodiment includes acrylic resin, inorganic thermal conductive particles modified by vinyl silane coupling agent, reactive diluent, and photoinitiator. The acrylic resin is a bisphenol A epoxy acrylate resin; the inorganic thermally conductive particles modified by the vinyl silane coupling agent are vinyl triethoxy silane modified nano Al 2 O 3 The reactive diluent is glycidyl methacrylate, the addition ratio is 20wt% of bisphenol A epoxy acrylate resin; the photoinitiator is (2,4,6-trimethylbenzoyl) diphenyl Based on phosphine oxide, the addition ratio is 3wt% of bisphenol A epoxy acrylate resin.

[0056] The preparation method of the high thermal conductivity photocurable coating for optical fiber includes the following steps:

[0057] (1) Using vinyl triethoxy silane for nano Al 2 O 3 Process to prepare nano Al modified by vinyl triethoxy silane 2 O 3 :

[0058] In a 500mL round bottom flask, ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap