Household garbage incineration flying dust electrode melting treatment and resourceful utilization method

A technology for waste incineration fly ash and recycling, applied in chemical instruments and methods, gas treatment, separation methods, etc., can solve the problems of high energy consumption, unfavorable promotion, and high treatment costs, achieve high investment, avoid acid gas corrosion, difficult effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

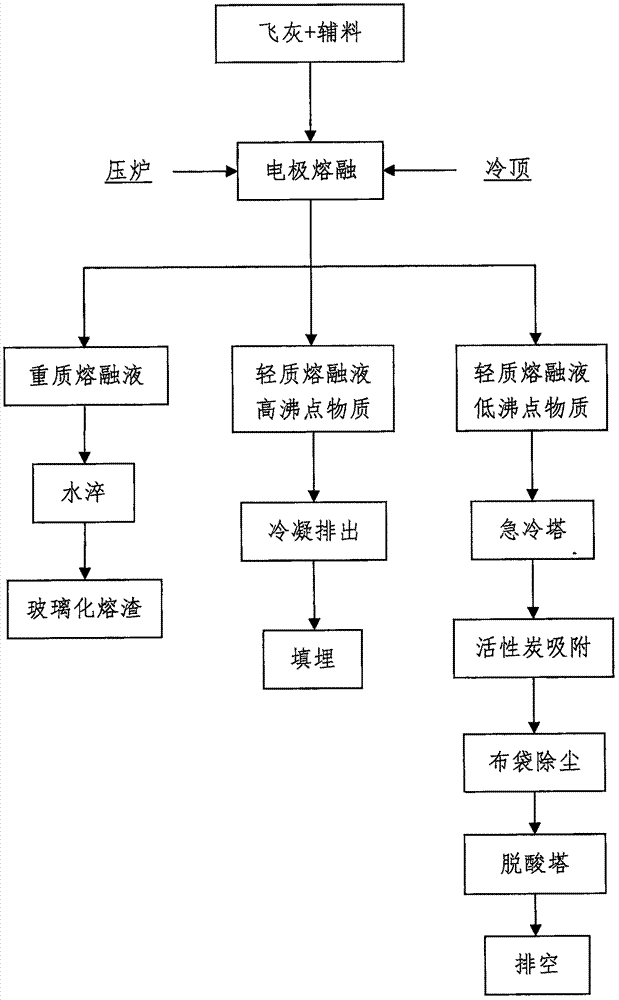

Image

Examples

Embodiment 1

[0025] Fly ash and auxiliary materials are weighed so that the amount of fly ash added is 90% of the total mass of the mixture. The auxiliary material is quartz sand, and the mixture is transported to the mixer by a semi-automatic control system. After stirring evenly, the mixture is sent to the molybdenum electrode melting furnace.

[0026] A 40cm-thick mixture layer is laid on the top of the molybdenum electrode melting furnace. When the melting temperature in the furnace is controlled at 1500°C, the material stays for 10 minutes before discharging, and the heavy molten liquid settles to the bottom of the melting furnace. The ascending channel and material channel space are discharged to the water quenching tank, and vitrified products are formed after quenching treatment; when the light molten liquid floats up and passes through the mixed material layer, it is preliminarily adsorbed and purified, and the high boiling point substances in the flue gas after preliminary purific...

Embodiment 2

[0035] Weigh the fly ash and auxiliary materials so that the amount of fly ash added is 75% of the total mass of the mixture. The auxiliary materials are broken glass, and the mixture is transported to the mixer by a semi-automatic control system. After stirring evenly, the mixture is sent to the graphite electrode melting furnace.

[0036] A 20cm-thick mixture layer is laid above the graphite electrode melting furnace and a water-cooled pipe is added on the top of the furnace to cooperate with the water-cooling method. When the melting temperature in the furnace is controlled at 1250°C, the material is discharged after staying for 50 minutes, and the heavy molten liquid settles to the bottom of the melting furnace. It is discharged to the water quenching pool through the liquid flow hole with electric heating, the ascending channel and the material channel space, and is subjected to rapid cooling to form a vitrified product; when the light molten liquid floats up and passes th...

Embodiment 3

[0045]Fly ash and auxiliary materials are weighed so that the amount of fly ash added is 50% of the total mass of the mixture. The auxiliary materials are a mixture of crushed glass and slag, and the mixture is transported to the mixer by a fully automatic control system. After stirring evenly, the mixture is Sent to tin oxide electrode melting furnace.

[0046] A 6cm-thick mixture layer is laid on the top of the molybdenum electrode melting furnace. When the melting temperature in the furnace is controlled at 900°C, the material stays for 80 minutes before discharging, and the heavy molten liquid settles to the bottom of the melting furnace, passing through the flow hole with electric heating, The ascending channel and material channel space are discharged to the water quenching tank, and vitrified products are formed after quenching treatment; when the light molten liquid floats up and passes through the mixed material layer, it is preliminarily adsorbed and purified, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com