Adsorption material and method for removing nuclide silver in reactor coolant by using it

An adsorption material and reactor technology, applied in chemical instruments and methods, nuclear engineering, other chemical processes, etc., can solve the problems of a large amount of high-level waste liquid accumulation, increased radiation field strength, and a large number of other problems, and achieve large adsorption capacity and dispersion. The effect of good sex and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

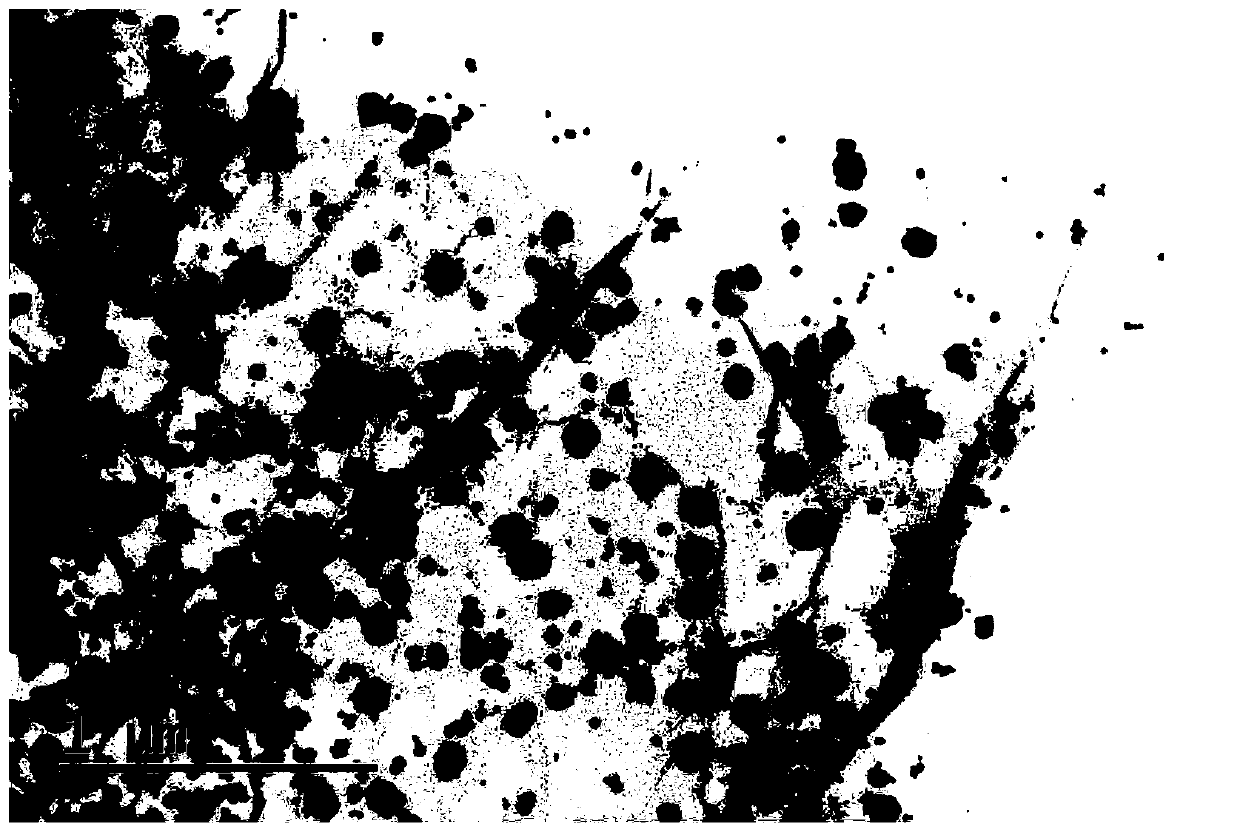

Image

Examples

Embodiment 1

[0030] Embodiment 1: Preparation of adsorbent material and its adsorption to nuclide silver in simulated coolant (1)

[0031] Weigh 50 mg of graphene oxide, dissolve it ultrasonically with 100 mL of ethylene glycol, add 0.25 g of ferric chloride and 0.5 g of polyethyleneimine (average molecular weight: 8000 Mw), and continue ultrasonication for 20 minutes. Afterwards, the mixed solution was transferred into a 200ml reaction kettle, sealed and placed in an oven at 180°C for 5 hours before the reaction was completed, and the product was washed and dried.

[0032] Take by weighing 25mg above-mentioned reaction product and add 50mL containing the boron of 1mg / L silver, lithium water, wherein boron concentration is 650mg / L (H 3 BO 3 ), the lithium concentration is 3.5mg / L (LiOH). Ultrasound for 20 minutes to make the adsorption material fully contact with the nuclide silver, let the mixed solution stand at room temperature for 30 minutes, and then use a magnet to separate the ads...

Embodiment 2

[0033] Embodiment 2: Preparation of adsorption material and its adsorption to nuclide silver in simulated coolant (two)

[0034] Weigh 200 mg of graphene oxide, dissolve it ultrasonically with 500 mL of ethylene glycol, add 0.5 g of ferric chloride and 1.5 g of polyethyleneimine (average molecular weight: 8000 Mw), and continue ultrasonication for 20 minutes. Afterwards, the mixed solution was transferred into a 1L reaction kettle, sealed and placed in an oven at 180°C, kept for 10 hours, and the reaction was completed, and the product was washed and dried.

[0035] Take by weighing 25mg above-mentioned reaction product and add 50mL containing the boron of 0.5mg / L silver, lithium water, wherein boron concentration is 1200mg / L (H 3 BO 3), the lithium concentration is 2.2mg / L (LiOH). Ultrasound for 10 minutes to fully contact the adsorption material with the nuclide silver, stir the mixture at room temperature (200 rpm) for 30 minutes, and then use a magnet to separate the ads...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com