Method for epitaxially growing ultrathin organic crystalline layers on surface and its applications

An epitaxial growth, organic semiconductor technology, applied in the direction of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of poor crystal quality of organic materials, unsuitable for LED displays, difficulties in ultra-thin organic semiconductors, etc., to achieve high quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0100] Example 1 Growth of C8-BTBT crystals on graphene

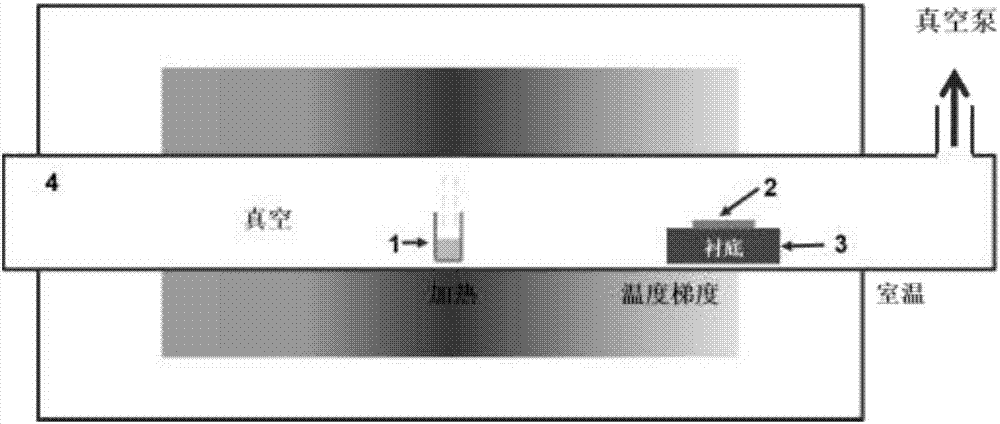

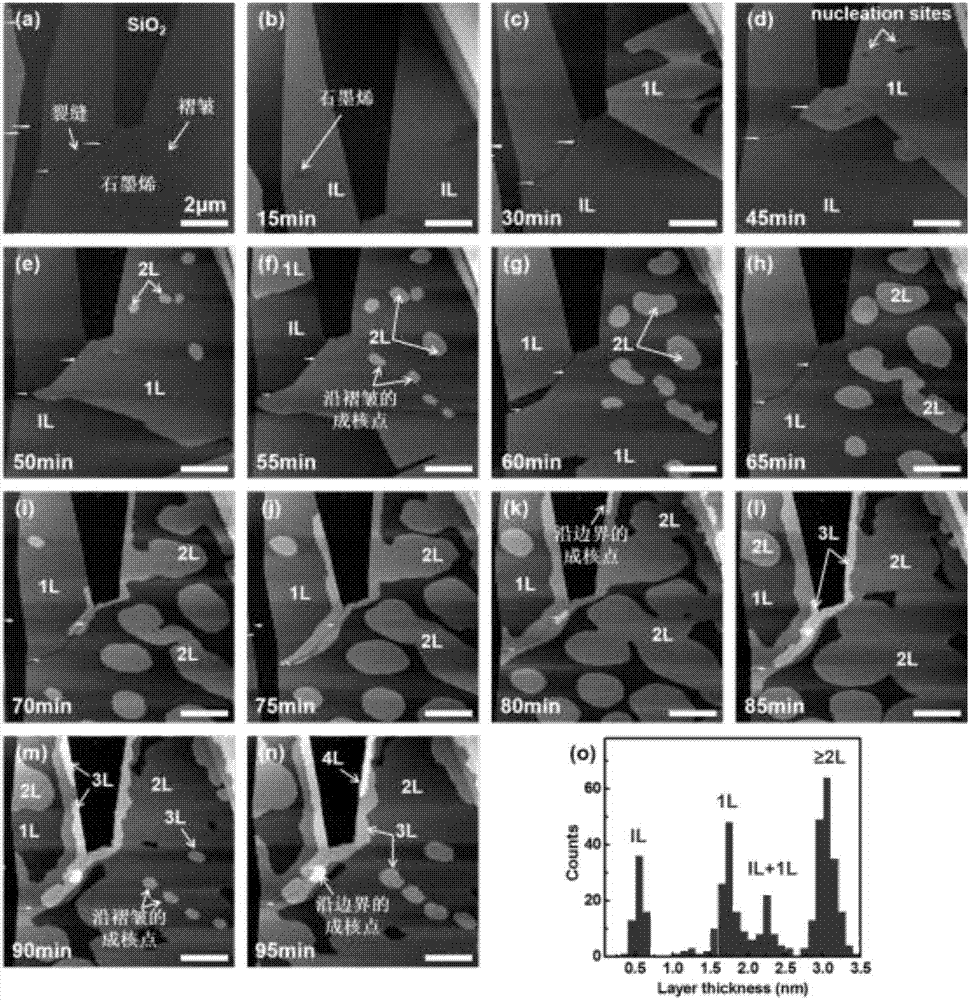

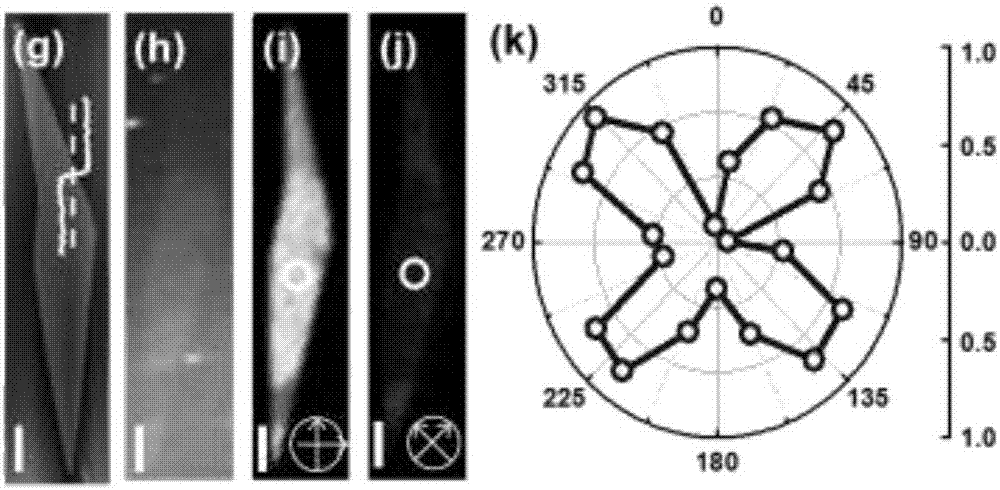

[0101] To prepare surface area up to 500um 2 Graphene samples on 285nm SiO 2 / Si substrate exfoliated graphene samples without heat treatment. The exfoliated graphene before growth was characterized by optical microscopy, AFM, and Raman spectroscopy to obtain thickness and morphology information. Growth in figure 1 In the tube furnace shown, in the tube furnace, an open container containing C8-BTBT powder (taken from Nippon KAYAKU Co., Ltd. without further purification) was placed in a quartz tube cavity (1.5 m long, 10cm in diameter). Then place the graphene sample at a distance of 20um from the source, seal the chamber of the quartz tube and evacuate it to 4x10 by a turbomolecular pump -6 Torr. For excellent reproducibility, the separation between the source and the graphene sample must be accurately measured for each experiment. The C8-BTBT powder was heated to 100 °C to start growth, after 50 min of growth, t...

example 2

[0102] Example 2: Using the same method as Example 1, except changing the distance between the source and the substrate to 10cm to grow C8-BTBT crystals, as a result, about 3 layers of C8-BTBT crystals will be epitaxial on graphene.

example 3

[0103] Example 3: Using the same method as Example 1, except changing the distance between the source and the substrate to 25cm to grow C8-BTBT crystals, as a result, about 2 layers of C8-BTBT crystals will be epitaxial on graphene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com