Comprehensive utilization method of acid-making flue gas produced in gold smelting plant

A flue gas and gas technology, applied in the field of comprehensive utilization of flue gas from gold smelters, can solve the problems of adding oxidants, high electricity costs, and high operating costs, and achieve low operating costs, low construction costs, and pollutant removal rates high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

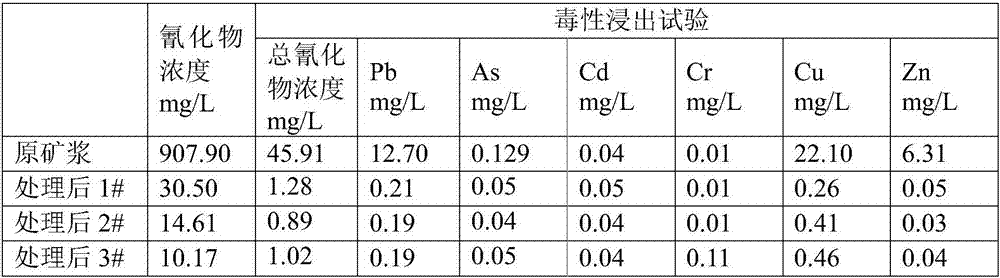

Embodiment 1

[0033] In a gold smelting plant, the raw ore contains between 28% and 30% sulfur, and the roasting pretreatment produces a high concentration of sulfur dioxide gas with a concentration of 160,000mg / m 3 to 180000mg / m 3 Among them, vanadium pentoxide catalyst is used to catalyze the oxidation of sulfur dioxide to produce acid, and the concentration of sulfur dioxide in the flue gas of acid production is 1600mg / m 3 to 1800mg / m 3 between. A sodium hydroxide solution with a mass concentration of 10% is configured to absorb the flue gas of acid production, and three-stage absorption is adopted to finally produce a sodium sulfite solution with a mass concentration of 10%. The total cyanide concentration in the cyanide pulp filtrate of the gold smelter is between 800mg / L and 1000mg / L, and the flow rate of the cyanide pulp is 5m 3 / h, pass it into stirring tank 1, and overflow to stirring tank 2 and stirring tank 3 in turn, add an equal amount of sodium sulfite solution to stirring ...

Embodiment 2

[0035] In a gold smelting plant, the raw ore contains between 30% and 32% sulfur, and the roasting pretreatment produces a high concentration of sulfur dioxide gas with a concentration of 180,000mg / m 3 up to 200000mg / m 3 Among them, vanadium pentoxide catalyst is used to catalyze the oxidation of sulfur dioxide to produce acid, and the concentration of sulfur dioxide in the flue gas of acid production is 1800mg / m 3 up to 2000mg / m 3 between. A sodium hydroxide solution with a mass concentration of 10% is configured to absorb the flue gas of acid production, and three-stage absorption is adopted to finally produce a sodium sulfite solution with a mass concentration of 10%. The total cyanide concentration in the cyanide pulp filtrate of the gold smelter is between 900mg / L and 1000mg / L, and the flow rate of the cyanide pulp is 15m 3 / h, pass it into stirring tank 1, and overflow to stirring tank 2 and stirring tank 3 in turn, add an equal amount of sodium sulfite solution to st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com