Preparation method of high-temperature interconnection welding spots based on foamy copper

A high-temperature-resistant interconnection and foamed copper technology, which is applied in welding equipment, non-electric welding equipment, manufacturing tools, etc., can solve the problem that foamed copper cannot meet the high temperature service requirements of solder joints, the growth rate of intermetallic compounds is different, and the roughness of IMC interface Increase and other problems, to achieve the effect of shortening the preparation cycle, good compactness, and short hot-press welding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Implementation example 1, refer to figure 1 :

[0053] Based on the above considerations, through a large number of experimental attempts and data analysis, we invented this method for preparing high-temperature-resistant solder joints based on foamed copper.

[0054] The method specifically includes the following steps (taking hydrochloric acid as the etchant, corroding to form copper foam, printing flux on both sides for thermocompression welding, and finally making it into a high-temperature resistant solder joint as an example):

[0055] (1) Through the above steps, the copper-aluminum alloy with a copper-aluminum atomic ratio of 4:6 is obtained by smelting, and an alloy sheet of 8mm*8mm*0.7mm is obtained after cutting, grinding and polishing, and then ultrasonically cleaned and dried for later use;

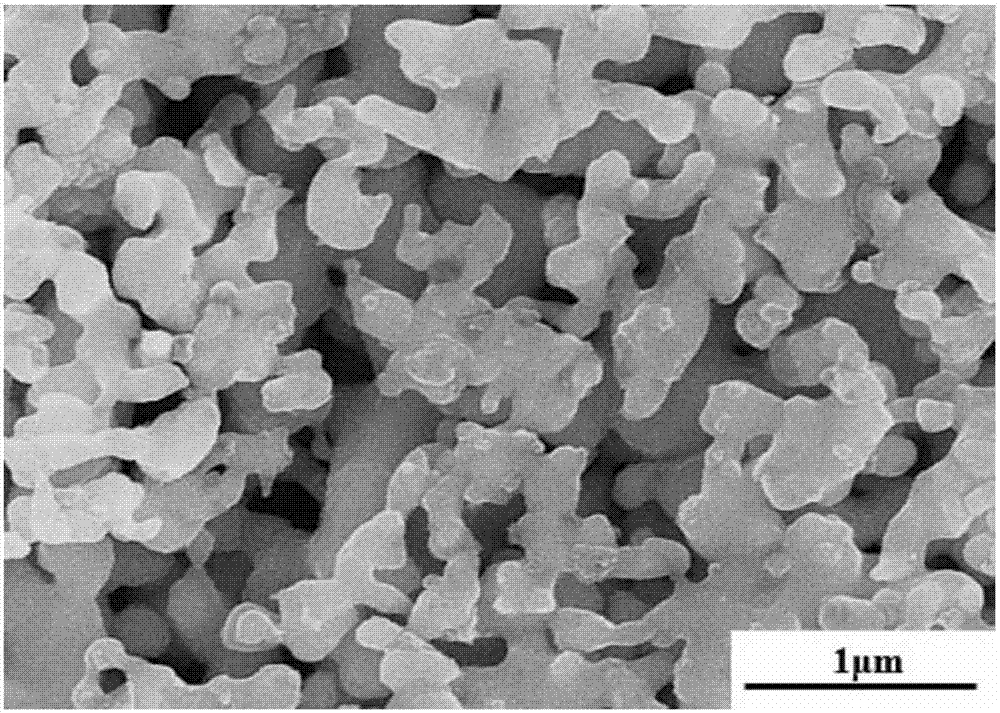

[0056] (2) Prepare a dilute hydrochloric acid corrosion solution with a concentration of 5%, place the alloy sheet obtained in step (1) in it, and heat it in a water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com