Method for preparing and comprehensively utilizing metal aluminum through coal ash pellet chlorination electrolysis

A technology for alumina and fly ash, which is applied in the field of fly ash pelletizing, chlorination electrolysis to prepare alumina and comprehensive utilization, can solve the problems of inability to comprehensively utilize, long process and high energy consumption, so as to improve resource utilization rate and reduce energy consumption. The effect of small emissions and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

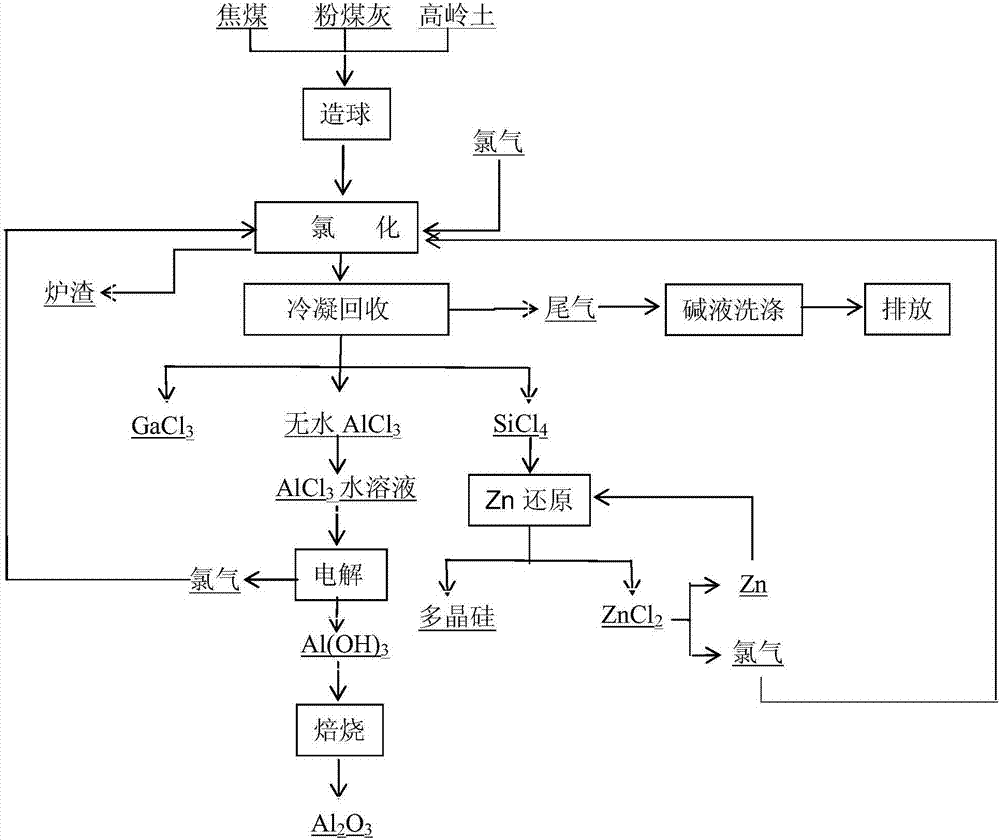

[0057] A method for preparing alumina and its comprehensive utilization by chlorination and electrolysis of fly ash pellets, the process flow chart is as follows figure 1 As shown, it specifically includes the following steps:

[0058] (1) Batching: get the high-alumina fly ash whose alumina content is 25%, and the silicon oxide content is 56%, according to the mass ratio, high-alumina fly ash: coking coal: kaolin=1: 0.2: 0.01 batching, mix evenly, Form a mixed material, add water glass of 1.0% of the total mass of the mixed material and 2.0% of the water of the total mass of the mixed material in the mixed material;

[0059] (2) Pelletizing: mix the mixed material, binder and water evenly, pelletize to obtain pellets with a particle size of 5 mm, and air-dry the pellets naturally for 10 hours;

[0060] (3) Pellet chlorination and separation: the pellets are chlorinated by microwave heating to form a mixture of anhydrous aluminum chloride, silicon tetrachloride and gallium ch...

Embodiment 2

[0067] A method for preparing alumina and its comprehensive utilization by chlorination and electrolysis of fly ash pellets, the process flow chart is as follows figure 1 As shown, it specifically includes the following steps:

[0068] (1) Batching: get the high-alumina fly ash whose alumina content is 36%, and the silicon oxide content is 40%, according to the mass ratio, high-alumina fly ash: coking coal: kaolin=1: 0.2: 0.05 ingredients, mix evenly, Form the mixed material, add the water glass of 1.7% of the total mass of the mixed material and the water of 4.3% of the total mass of the mixed material in the mixed material;

[0069] (2) Pelletizing: mix the mixed material, binder and water evenly, pelletize to obtain pellets with a particle size of 12 mm, and air-dry the pellets naturally for 16 hours;

[0070] (3) Pellet chlorination and separation: the pellets are chlorinated by microwave heating to form a mixture of anhydrous aluminum chloride, silicon tetrachloride and ...

Embodiment 3

[0077] A method for preparing alumina and its comprehensive utilization by chlorination and electrolysis of fly ash pellets, the process flow chart is as follows figure 1 As shown, it specifically includes the following steps:

[0078] (1) Batching: get the high-alumina fly ash whose alumina content is 30%, and the silicon oxide content is 48%, according to the mass ratio, high-alumina fly ash: coking coal: kaolin=1: 0.3: 0.04 batching, mix evenly, Form the mixed material, add the water glass of 1.6% of the total mass of the mixed material and the water of 4.0% of the total mass of the mixed material in the mixed material;

[0079] (2) Pelletizing: mix the mixed material, binder and water evenly, pelletize to obtain pellets with a particle size of 16 mm, and air-dry the pellets naturally for 20 hours;

[0080] (3) Pellet chlorination and separation: the pellets are chlorinated by microwave heating to form a mixture of anhydrous aluminum chloride, silicon tetrachloride and gal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com