Preparing method of microcapsules capable of coating hindered amine stabilizer, hindered phenolic stabilizer and organic dye together

A technology of hindered amines and hindered phenols, applied in the direction of microcapsule preparation, microsphere preparation, etc., can solve the problems of attack damage and hydroxide attack damage, and achieve the effect of uniform coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A kind of preparation method of the microcapsule of co-coating hindered amine stabilizer, hindered phenol stabilizer and organic dye, it comprises the following steps:

[0030] (1) Benzidine Yellow H10G: hindered amine light stabilizer Tinuvin770 [scientific name (bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate]: hindered phenol antioxidant 264 [Scientific name 2,6-di-tert-butyl-p-cresol] After mixing at a weight ratio of 3:1:1, fully dissolve it with 10 parts of acetone;

[0031] (2) Pour the solution in step (1) into 40 parts of hydrophobic gas-phase nano-silica particles (Hydrophobic-260 type), and after fully absorbing, dry at room temperature. After the surface of the silica particles is dry, put them in a vacuum Vacuum the oven and dry at 40°C for 2 hours;

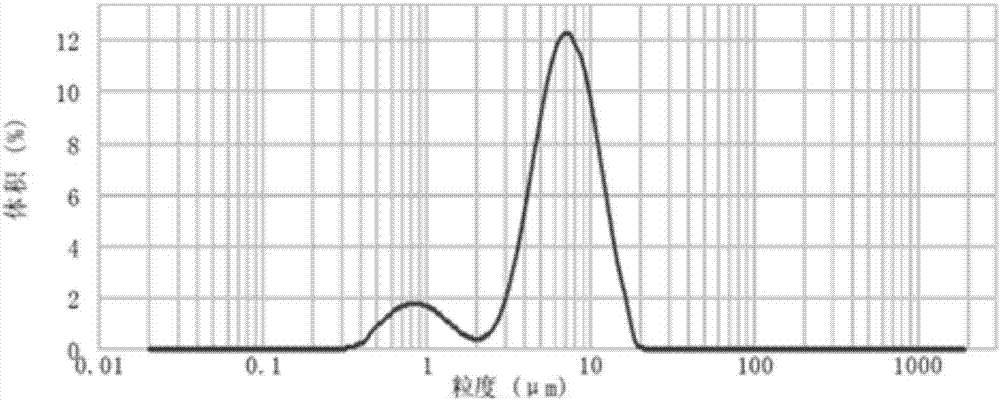

[0032] (3) Pour the silicon dioxide particles obtained in step (2) into a grinder containing pure water and a dispersant, grind and disperse, filter, and dry. Then add the dried silicon dioxide particles int...

Embodiment 2

[0041] The microcapsules prepared in Example 1 were added to screen printing ink, and screen printed on a plastic substrate to obtain product A. In addition, the same content of benzidine yellow H10G and hindered amine and hindered phenolic stabilizers were directly inserted into the screen printing ink for screen printing without coating to obtain product B; using Q-SUN Xe-1 Xenon Test Chamber xenon lamp The aging test box was tested, and it was found that the light stable life of the dye in product B was 240 hours, while the light stable life of the dye in product A was increased to 530 hours.

Embodiment 3

[0043] The microcapsules prepared in Example 1 were added into PVC powder, and an injection molding machine was used to carry out a mixing experiment at 170 degrees. The test results show that the microcapsules produced by this patented technology can remain stable under high temperature and high shear conditions, and the HCl gas decomposed by PVC under the protection of the capsule shell does not destroy the molecular structure of benzidine yellow H10G inside the capsule. The resulting PVC mixture was still yellow.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com