A kind of preparation method of high temperature resistant ceramic track

A technology for high-temperature-resistant ceramics and crawlers, which is applied in the field of high-temperature-resistant ceramic crawlers and high-temperature-resistant ceramic crawlers. It can solve the problems of inability to compete with metals and their composite materials, delamination of green bodies, low strength of green bodies, and large dispersion of ceramic materials. problems, to achieve good industrial application prospects, good dimensional stability, and good self-lubricating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The process of the preparation method of the high-temperature-resistant ceramic crawler involved in this embodiment includes three steps of powder preparation, green body molding and microwave sintering:

[0019] (1), powder preparation: powdered 3Y-TZP with a purity greater than 99% and a particle size of less than 0.5 μm and powdered Al with a purity of 99% and a particle size of 1 μm 2 o 3 Prepare a mixed powder with a mass percentage of 10%, the mixed powder is pulverized by a ball mill for 10 hours, dried and filtered through a 40-mesh sieve to obtain a powder, and the preparation of the powder is completed;

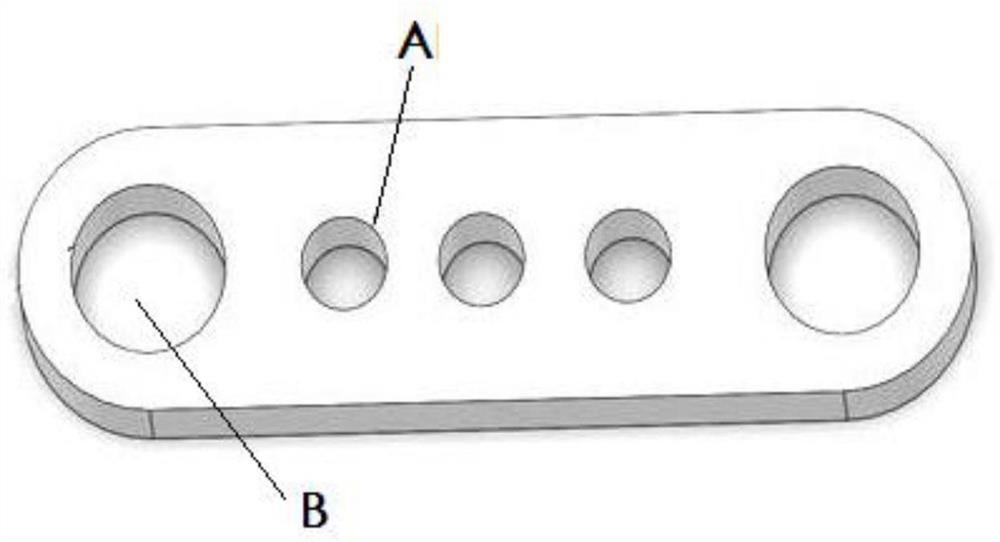

[0020] (2), green body molding: carry out 100MPa dry pressing for 3-5 minutes and 250MPa cold isostatic pressing for 8-12 minutes successively to form the green body of crawler belt to powder;

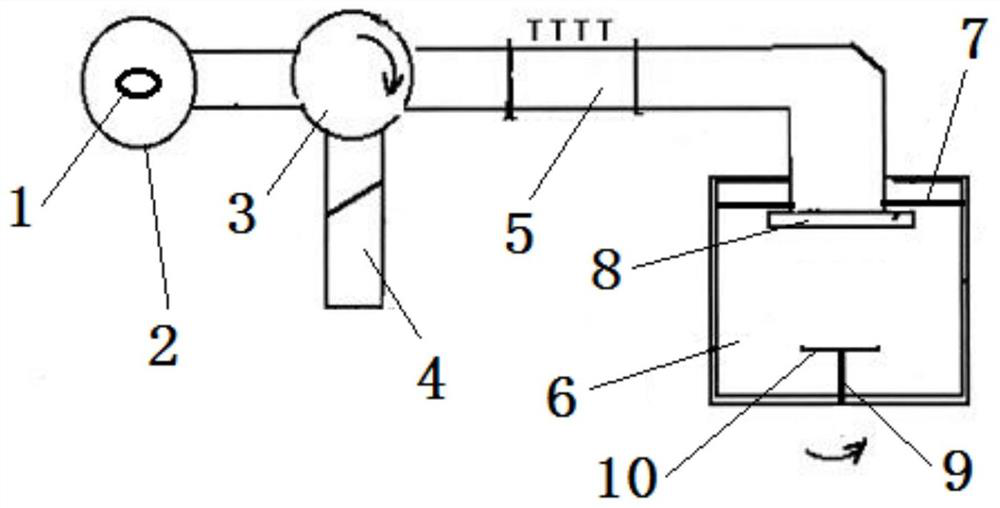

[0021] (3) Microwave sintering: put the green body into Al which is filled with SiC powder 2 o 3 Crucible, Al 2 o 3The crucible has a cylinder with a round hole ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com