Synthesis method of mesoporous carbon nanosphere loaded manganous oxide material

A manganese oxide material and technology of synthesis method, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of increasing electrical conductivity, poor electrical conductivity, etc., and achieve high oxygen reduction catalytic activity, The method is simple and the preparation cost is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Preparation of SiO 2 @PANI material:

[0027] Weigh 1 g (NH 4 ) 2 S 2 o 4 Dissolve in 2 mL of water and set aside.

[0028] Take 1 mL of SiO 2 Mix sol (purchased from Sigma Aldrich), 10 mL ultrapure water, and 5 mL 1 mol / L HCl aqueous solution, then add 0.4 g of aniline to the mixture, sonicate for 1 h under ice-bath conditions, and then Stir for 20min; Then (NH 4 ) 2 S 2 o 4 The solution was added dropwise to the mixture, and stirred vigorously under ice bath for 24 h. After the reaction, the product was washed three times with absolute ethanol, and the solid phase was taken, that is, silicon dioxide coated with polyaniline (SiO 2 @PANI) and dried in a 50°C oven for later use.

[0029] (2) Preparation of MPNs material:

[0030] Take 0.4 g polyaniline coated silica (SiO 2 @PANI) was dissolved in 25 ml NaOH aqueous solution with a concentration of 0.5 mol / L, heated to 60 °C, stirred and reacted for 6 h, the product was washed three times with ultrapure ...

Embodiment 2

[0037] According to the method of steps (1) and (2) in Example 1, MPNs materials were obtained.

[0038] (3) Preparation of MnO@N-MCNs material:

[0039] Dissolve 0.1 g of mesoporous polyaniline (MPNs) in 40 mL of ultrapure water, sonicate for 20 min, adjust the pH to 1-2, and then add 10 mL of KMnO with a concentration of 0.1 mol / L 4 aqueous solution, at room temperature, stirred and reacted for 4 h, then washed three times with ultrapure water, took the solid phase and dried it in an oven at 50 °C to obtain polyaniline-supported manganese dioxide (MnO 2 @PANI).

[0040] in N 2 Under the conditions, the prepared polyaniline supported manganese dioxide (MnO 2 @PANI) was placed in a crucible and calcined at 900 °C for 2 h under the protection of nitrogen to obtain the MnO@N-MCNs material.

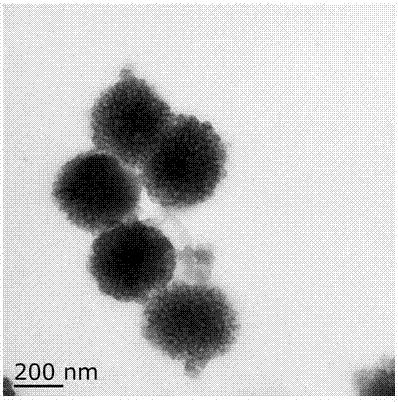

[0041] image 3 is the transmission electron microscope image of the calcined MnO@N-MCNs, by image 3 Visible: With KMnO 4 When the amount of aqueous solution was increased to 10 mL,...

Embodiment 3

[0043] According to the method of steps (1) and (2) in Example 1, MPNs materials were obtained.

[0044] (3) Preparation of MnO@N-MCNs material:

[0045]Dissolve 0.1 g of mesoporous polyaniline (MPNs) in 40 mL of ultrapure water, sonicate for 20 min, adjust the pH to 1-2, and then add 14 mL of KMnO with a concentration of 0.1 mol / L 4 aqueous solution, at room temperature, stirred and reacted for 4 h, then washed three times with ultrapure water, took the solid phase and dried it in an oven at 50 °C to obtain polyaniline-supported manganese dioxide (MnO 2 @PANI).

[0046] in N 2 Under the conditions, the prepared polyaniline supported manganese dioxide (MnO 2 @PANI) was placed in a crucible and calcined at 900 °C for 2 h under the protection of nitrogen to obtain the MnO@N-MCNs material.

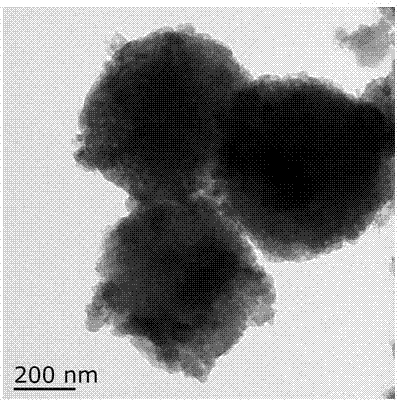

[0047] Figure 4 is the transmission electron microscope image of the calcined MnO@N-MCNs, by Figure 4 Visible: join KMnO 4 When the aqueous solution was 14mL, the basic morphology o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mesopore | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com