Preparation method of chitin porous hemostatic microsphere

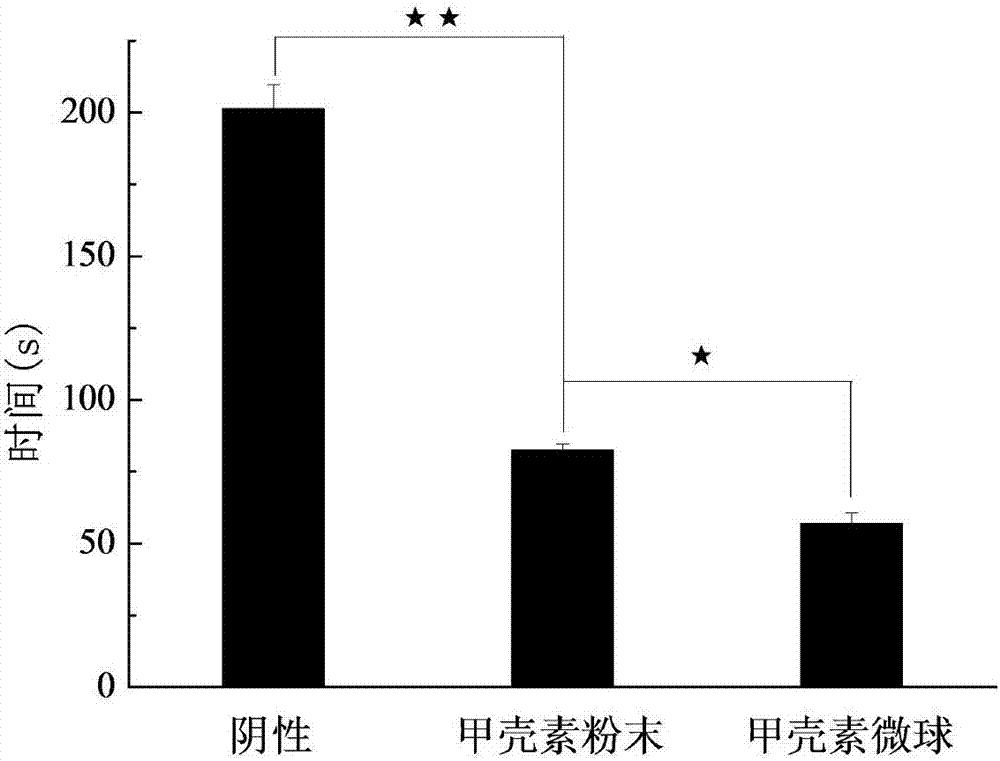

A chitin and microsphere technology, applied in the fields of medical science, surgery, surgical adhesives, etc., can solve the problems of large consumption of organic solvents and surfactants, high preparation cost, and achieve the effect of fast preparation speed and uniform particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Preparation of 1.5% chitin solution: Dissolve 11g of sodium hydroxide and 4g of urea in 83.5g of water, then add 1.5g of chitin into the solvent, and stir for 5 minutes at room temperature. The mixed solution was frozen at -30°C for 2 hours, then taken out and stirred until uniform, and then continued to freeze at -30°C. After 4h and 8h, repeat the stirring / freezing process until it dissolves, filter to obtain a clear and transparent liquid, add 0.1g Tween, stir evenly, and store at 4°C for later use.

[0028] 2. Preparation of coagulation solution: Dissolve 25mL of sulfuric acid in 225mL of hydroalcoholic solution (V water: V ethanol = 1:1) as the coagulation solution.

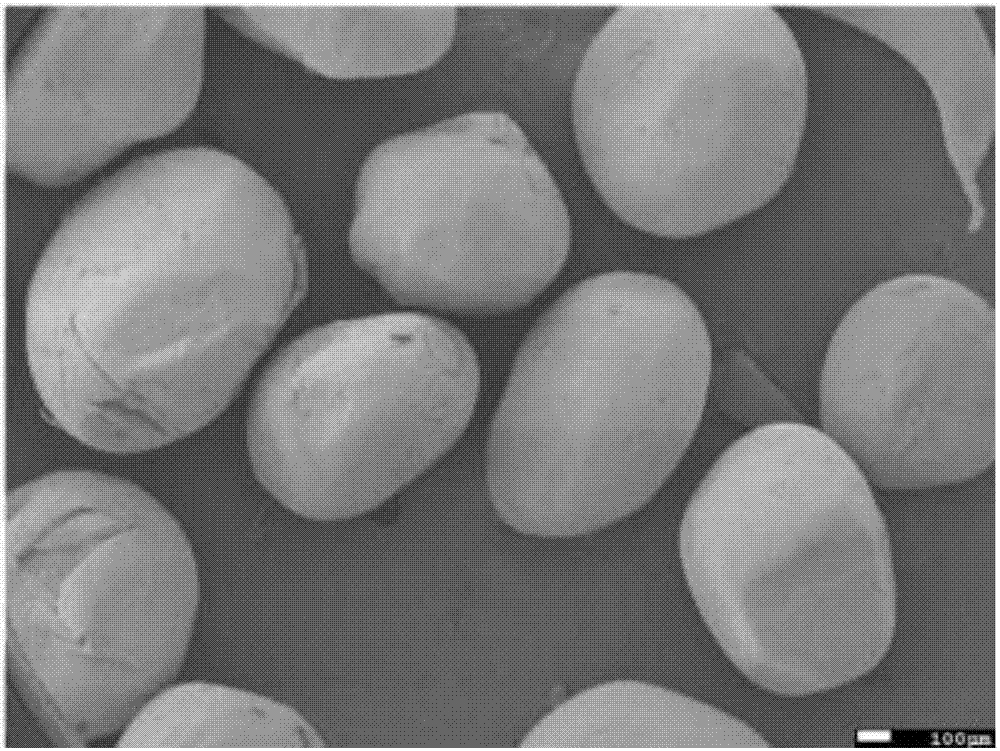

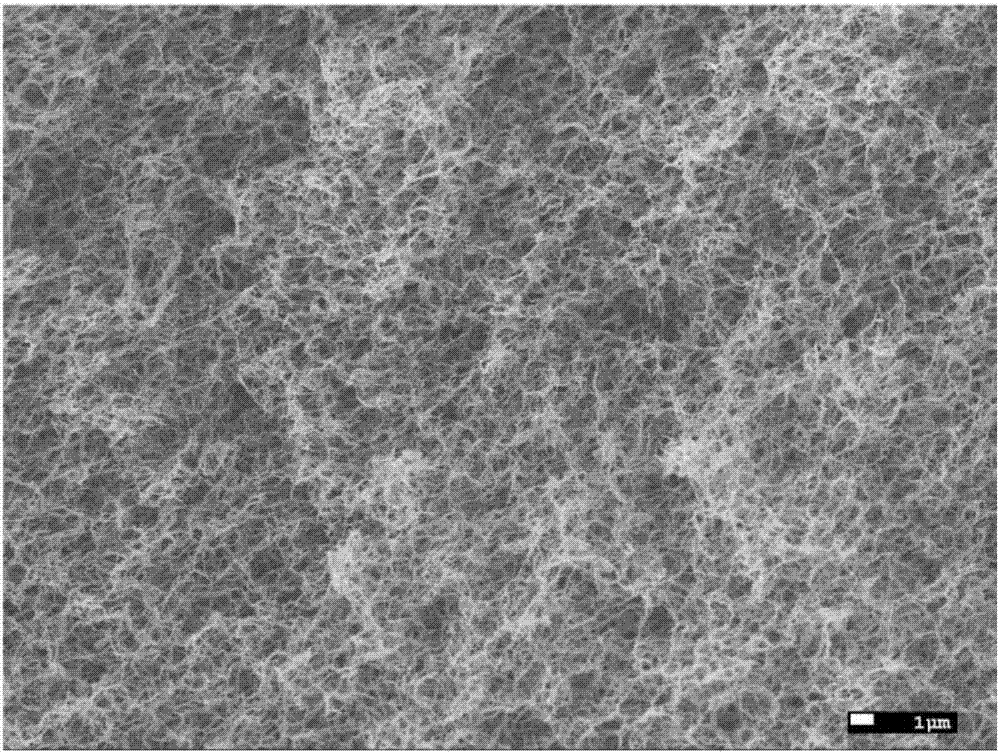

[0029] 3. Preparation of microspheres: inject 20 mL of chitin solution into a 20 mL syringe, and obtain chitin microspheres by electrostatic spraying. Electrostatic spraying conditions are: feed rate: 60 μL / min, voltage: 14 kV.

[0030] 4. Washing and drying: collect the above-mentioned chitin mic...

Embodiment 2

[0033] 1. Preparation of 1.5% chitin solution: Dissolve 11g of sodium hydroxide and 4g of urea in 83.5g of water, then add 1.5g of chitin into the solvent, and stir for 5 minutes at room temperature. The mixed solution was frozen at -30°C for 2 hours, then taken out and stirred until uniform, and then continued to freeze at -30°C. Repeat the stirring / freezing process after 4h and 8h until dissolved, filter to obtain a clear liquid, and store at 4°C for later use.

[0034] 2. Preparation of coagulation solution: Dissolve 25mL of sulfuric acid in 225mL of hydroalcoholic solution (V water: V ethanol = 1:1) as the coagulation solution.

[0035] 3. Preparation of microspheres: inject 20 mL of chitin solution into a 20 mL syringe, and obtain chitin microspheres by electrostatic spraying. Electrostatic spraying conditions are: feed rate: 60 μL / min, voltage: 10 kV.

[0036] 4. Washing and drying: collect the above-mentioned chitin microspheres by filtration, put them into 1M 150mL h...

Embodiment 3

[0038] 1. Preparation of 2.0% chitin solution: Dissolve 11g of sodium hydroxide and 4g of urea in 83g of water, then add 2g of chitin into the solvent, and stir for 5 minutes at room temperature. The mixed solution was frozen at -30°C for 2 hours, then taken out and stirred until uniform, and then continued to freeze at -30°C. After 4h and 8h, repeat the stirring / freezing process until dissolved, filter to obtain a clear liquid, add Tween-80 to make its concentration reach 0.05%, and stir evenly. Store at 4°C for later use.

[0039] 2. Preparation of coagulation solution: Dissolve 25mL of sulfuric acid in 225mL of hydroalcoholic solution (V water: V ethanol = 1:1) as the coagulation solution.

[0040] 3. Preparation of microspheres: inject 20 mL of chitin solution into a 20 mL syringe, and obtain chitin microspheres by electrostatic spraying. Electrostatic spraying conditions are: feed rate: 60 μL / min, voltage: 10 kV.

[0041] 4. Washing and drying: collect the above-mentio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com