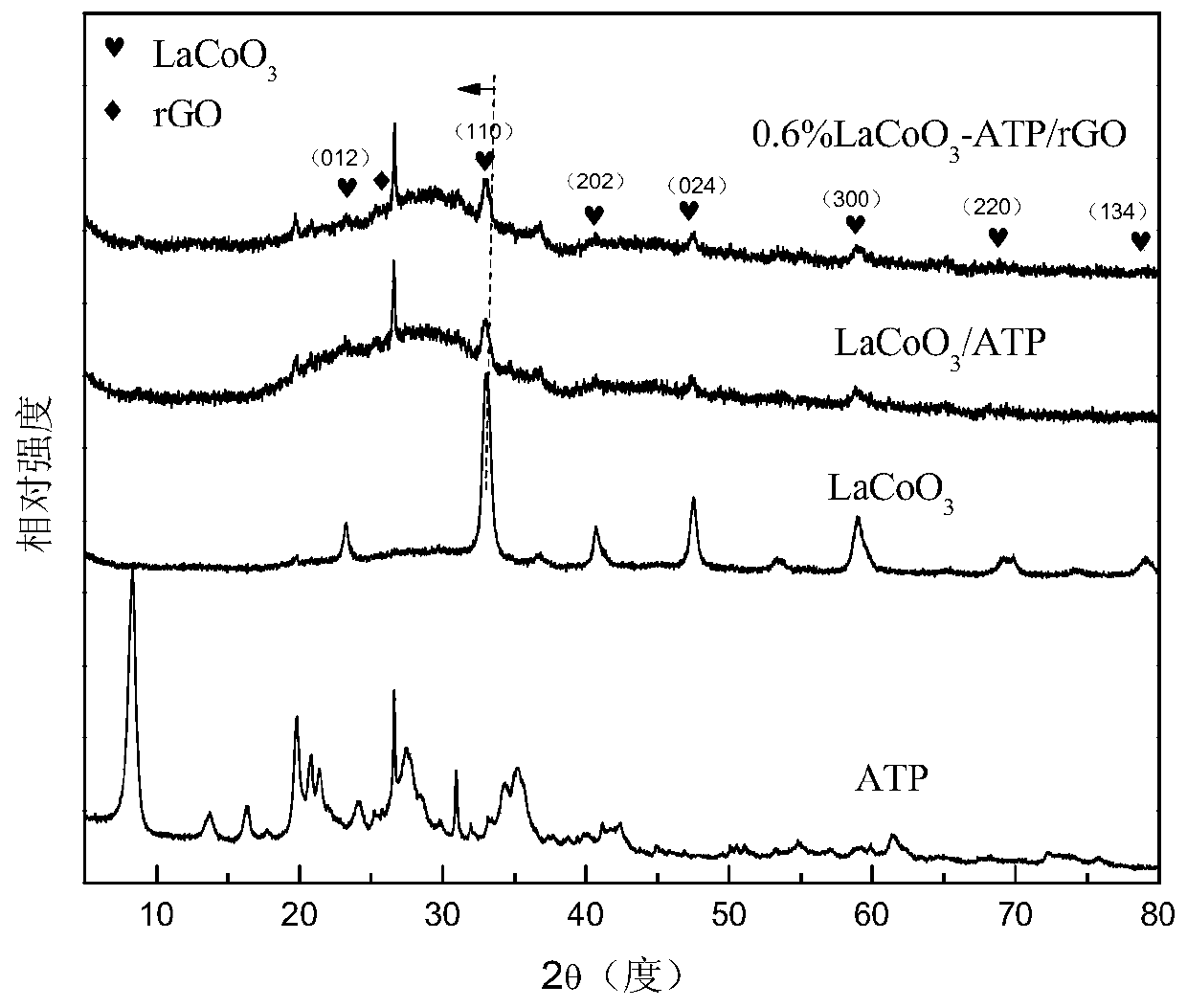

A kind of lanthanum cobaltate/attapulgite/reduced graphene oxide nanostructure composite material and its preparation method and application

A technology of attapulgite and composite materials, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, separation methods, etc., can solve problems that restrict the application prospects of photo-SCR, and achieve favorable catalytic Activity, inhibition of stacking, effect in favor of adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

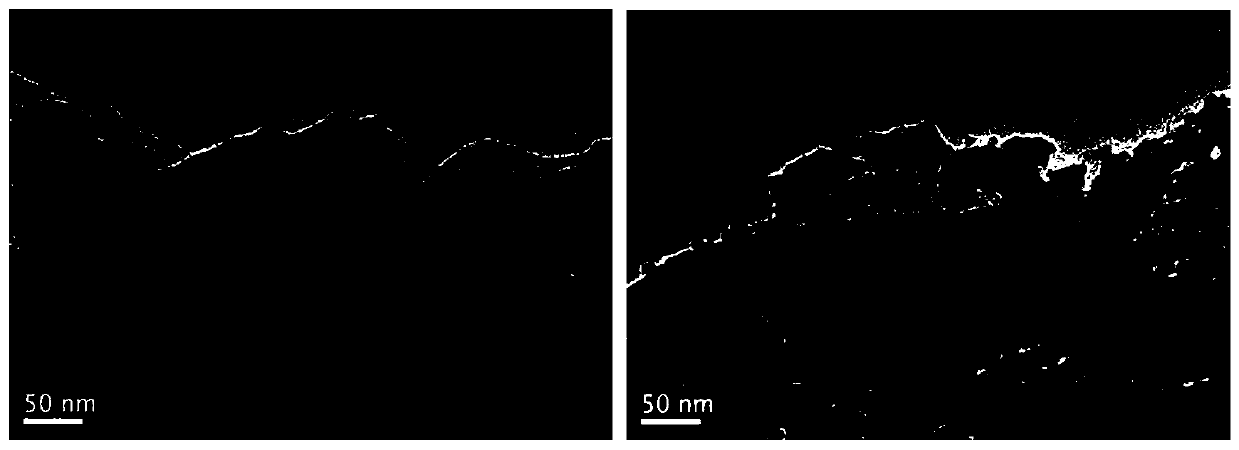

[0027] (1) Add 0.39g of lanthanum nitrate, 0.35g of cobalt nitrate, 0.48g of citric acid, and 1.0g of attapulgite into 100ml of deionized water and stir, then transfer to an 80°C water bath to evaporate to obtain a wet gel, dry at 80°C, and ℃ calcining (heating rate 2°C / min) for 2 hours, drying and grinding to obtain lanthanum cobaltate / attapulgite, then add 1g of the obtained lanthanum cobaltate / attapulgite to 50mL deionized water, add hydrochloric acid to adjust the pH to 3. The positively charged lanthanum cobaltate / attapulgite aqueous dispersion is obtained;

[0028] (2) After the graphite oxide prepared by the Hummers method is ultrasonically dispersed in deionized water, hydrazine hydrate is added dropwise and reduced in a water bath at 90° C., washed and filtered, and then dried to obtain negatively charged reduced graphene oxide;

[0029] (3) The negatively charged reduced graphene oxide 0.006g obtained in step (2) is ultrasonically dispersed in 50mL deionized water, a...

Embodiment 2

[0033] (1) with embodiment 1;

[0034] (2) with embodiment 1;

[0035] (3) The negatively charged reduced graphene oxide 0.004g obtained in step (2) is ultrasonically dispersed in 50mL deionized water, and the positively charged lanthanum cobaltate / attapulgite water obtained in step (1) is added Dispersion liquid, stirred in 80°C water bath, dried, and ground to obtain 0.4% LaCoO 3 / ATP / rGO nanostructured composites.

Embodiment 3

[0037] (1) with embodiment 1;

[0038] (2) with embodiment 1;

[0039] (3) The negatively charged reduced graphene oxide 0.005g obtained in step (2) is ultrasonically dispersed in 50mL deionized water, and the positively charged lanthanum cobaltate / attapulgite water obtained in step (1) is added Dispersion, stirred in 80°C water bath, dried, and ground to obtain 0.5% LaCoO 3 / ATP / rGO nanostructured composites.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com