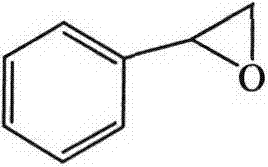

Method for preparing mandelic acid from styrene oxide

A technology for oxidizing styrene and mandelic acid, which is applied in the chemical industry and can solve the problems of large amount of waste water and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

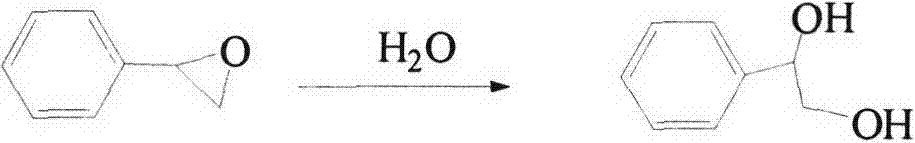

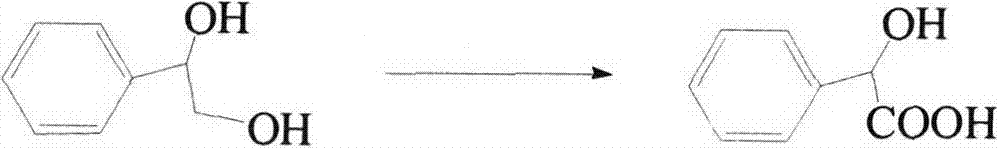

Method used

Image

Examples

Embodiment 1

[0040] Get 240.3g (2mol) styrene oxide and join in the mixed solution of 500g ethylene glycol and 200g water, add the NY2 catalyst of 35g (Nanjing Technological University and Yangzi Petrochemical Production), after 140 ℃ of reaction 2 hours, underpressure distillation, concentrate, The catalyst, ethylene glycol and 271.5 g of phenyl glycol were recovered by filtration, with a yield of 98.3%.

[0041] In the sodium hydroxide solution (20%) of 250g (0.81mol) phenylethylene glycol and 430g, add 1.3g charcoal supported Pd-Au catalyst (CRI Catalyst Company, the loading capacity of Pd-Au is 0.5%, Pd / Au =0.3:2), stir evenly, heat to 90°C, feed air (40mL / min) while stirring, after reacting for 6 hours, add hydrochloric acid to adjust the pH value to 7-7.5, filter and recover the catalyst, add 100g Calcium chloride was filtered again to obtain calcium mandelic acid powder, the collected mandelic acid powder was acidified with dilute hydrochloric acid to pH=3-4, concentrated and crysta...

Embodiment 2

[0043] Get 800g (6.66mol) styrene oxide and join in the mixed solution of 800g ethylene glycol and 800g water, add 35g of NY2 and 55g NY3 catalyst, after reacting for 5 hours at 130 DEG C, distill under reduced pressure, concentrate, filter and recover catalyst, ethylene glycol Alcohol and collected phenyl glycol 870.4g, yield 94.6%.

[0044]In the sodium hydroxide solution (40%) of 850g (6.15mol) phenyl ethylene glycol and 1230g, add 85g charcoal supported Pd-Au catalyst (self-made, the load capacity of Pd-Au is 1.5%, Pd / Au=0.3: 1), stir evenly, heat to 95°C, feed air (60mL / min) while stirring, after reacting for 9 hours, add hydrochloric acid to adjust the pH value to 7-7.5, filter and recover the catalyst, add 680g calcium chloride to the filtrate , filtered again to obtain calcium mandelic acid powder, collected mandelic acid powder and acidified with dilute hydrochloric acid to pH = 3-4, concentrated and crystallized to obtain 925 g of mandelic acid, with a yield of 98.86...

Embodiment 3

[0046] Take 300g (2.5mol) of styrene oxide and add it to a mixed solution of 125g ethylene glycol and 375g water, add 125g of NY1 catalyst, react at 60°C for 14 hours, distill under reduced pressure, concentrate, filter and recover catalyst, ethylene glycol and collect 317.8 g of phenyl glycol, yield 92%.

[0047] In the sodium hydroxide solution (20%) of 300g (2.17mol) phenyl glycol and 520g, add 1.5g charcoal supported Pd-Au catalyst (self-made, the loading capacity of Pd-Au is 5%, Pd / Au=0.1 : 2), stir evenly, heat to 95°C, feed air (60mL / min) while stirring, after reacting for 2 hours, add hydrochloric acid to adjust the pH value to 7-7.5, filter and recover the catalyst, add 240g chloride Calcium, filtered again to obtain calcium mandelic acid powder, collected mandelic acid powder and acidified with dilute hydrochloric acid to pH = 3-4, concentrated and crystallized to obtain 325.6 g of mandelic acid, with a yield of 98.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com