Method for synthesizing acetyl propionate by catalyzing alcoholysis of biomass carbohydrate through microwave assistance in presence of phosphotungstic acid and phosphowolframate

A technology of levulinic acid ester and carbohydrate, applied in the field of synthesis and preparation of levulinic acid ester, can solve the problems of unsatisfactory catalytic effect, inability to effectively recycle and reuse the catalyst, long reaction time, etc. The effect of high rate and short response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

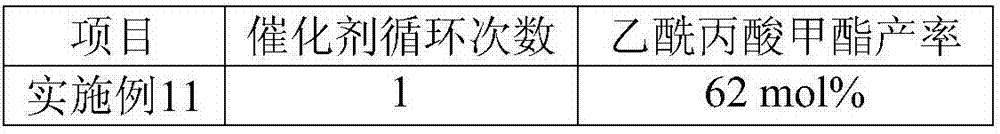

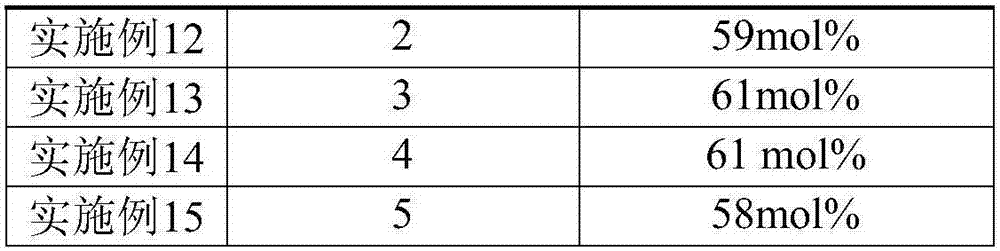

Examples

preparation example Construction

[0044] The preparation methods of iron phosphotungstate, indium phosphotungstate and chromium phosphotungstate are basically the same as those of aluminum phosphotungstate.

[0045] In the following examples, the conditions of gas chromatography analysis are as follows:

[0046] Chromatographic column: DB-5 (30m×0.250mm, 0.25μm); hydrogen flame ionization detector (FID); heating program: initial temperature 60°C, keep 3min; increase to 180°C at 6°C / min, keep 3min; Then rise to 270°C at 10°C / min and keep for 15min; the temperature of the injection port is 250°C; the temperature of the detector is 270°C; the injection volume is 1 μL; the carrier gas is nitrogen; ester yield.

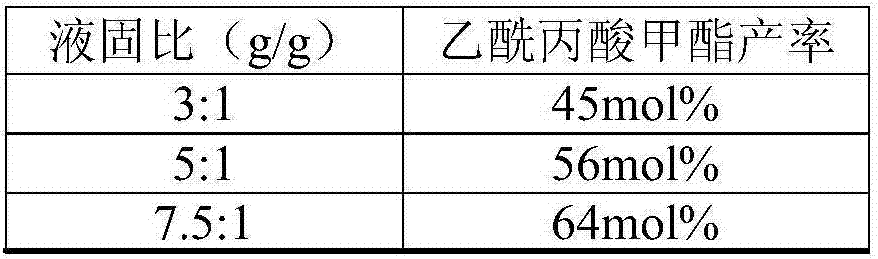

Embodiment 1

[0048] Add 2g glucose, 15g methanol (liquid-solid ratio 7.5:1g / g) and 0.4mmol aluminum phosphotungstate to the PTFE tube, add a stirrer, pass in argon gas and put it into the microwave reaction chamber after installation, and use magnetic force The stirrer pre-stirred for 1 min to mix the reactants evenly; set the microwave power to 600W, and raised the temperature to 160°C within 2 min. The temperature was maintained for 30 min under 500W microwave power, and the reaction was carried out under constant stirring; after the reaction was completed, the temperature was rapidly cooled to room temperature using an ice-water bath, and the reaction mixture was taken out. The reaction mixture was taken and analyzed by gas chromatography to calculate that the yield of methyl levulinate was 64mol%.

Embodiment 2

[0050] Add 1g sucrose, 15g ethanol (liquid-solid ratio 15:1g / g) and 0.3mmol phosphotungstic acid to the PTFE tube, add a stirrer, pass in argon gas, put it into the microwave reaction chamber after installation, and use magnetic stirring Pre-stirrer for 1 min to mix the reactants evenly; set the microwave power to 600W, and raise the temperature to 190°C within 2 min. The temperature was maintained for 30 min under 500W microwave power, and the reaction was carried out under constant stirring; after the reaction was completed, the temperature was rapidly cooled to room temperature using an ice-water bath, and the reaction mixture was taken out. The reaction mixture was taken and analyzed by gas chromatography to calculate that the yield of ethyl levulinate was 45 mol%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com