Super absorbent resin and preparation method and application thereof

A technology of superabsorbent resin and tapioca starch, which is applied in the direction of instruments, optics, optical components, etc., can solve the problems of poor compression resistance, water loss, and low salinity resistance, and achieve enhanced shear resistance and longitudinal stretching Ability, the effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

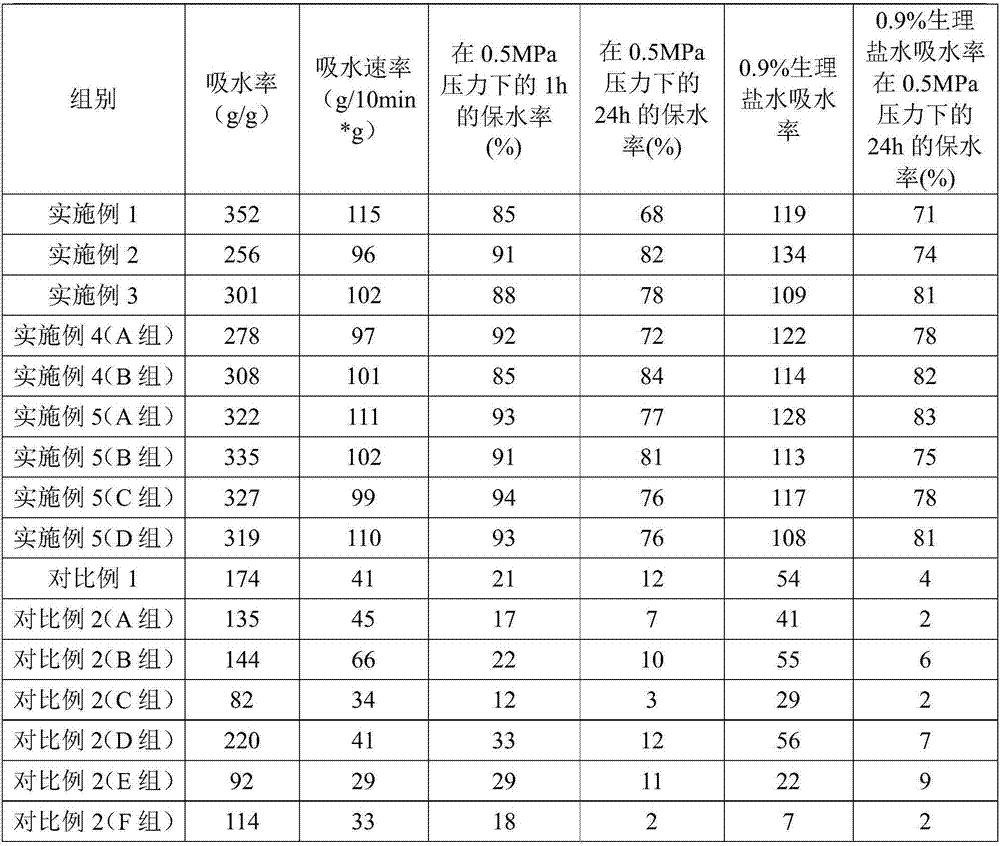

Examples

Embodiment 1

[0049]1) Pre-stage starch gelatinization treatment: Take 225 grams of cassava starch, 10 kg of distilled water, add 40 grams of 40% by mass sodium hydroxide to fully dissolve it at 35-40 ° C and mechanically stir at a speed of 55-65 rpm to gelatinize the starch The solution is transparent, and 125 grams of 20% by mass maleic acid solution is added to adjust the neutralization degree to 80%. (Nitrogen protection throughout the process)

[0050] 2) Take 100 grams of polyvinyl alcohol, heat 1-2 kilograms of distilled water in a water bath to 90-95° C., and mechanically stir at a speed of 30-50 rpm for 1-2 hours. (Nitrogen protection throughout the process)

[0051] 3) Add 80 g of hydroxypropyl methylcellulose to the tapioca starch solution after gelatinization and heat to 55-65° C. Mechanically stir at a speed of 45-55 rpm for 1-2 hours and then heat up to 65° C. (Nitrogen protection throughout the process)

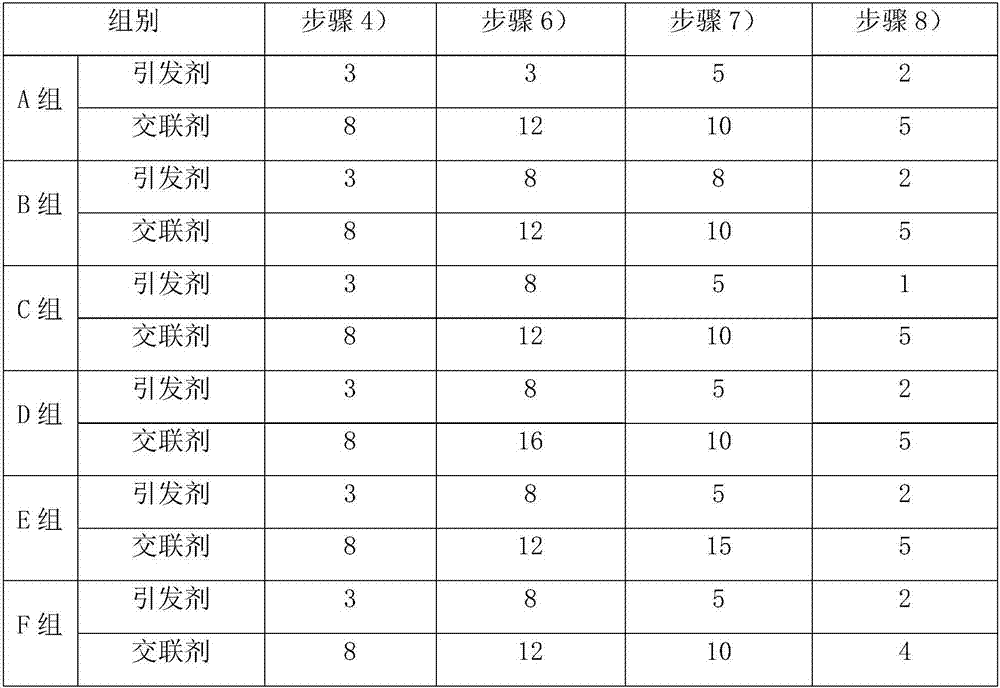

[0052] 4) Add 3 grams of potassium persulfate and 8 grams of N,N-met...

Embodiment 2

[0061] 1) Pre-stage starch gelatinization treatment: take 250 grams of cassava starch, 10 kg of distilled water, add 40 grams of 40% by mass sodium hydroxide to fully dissolve at 35-40 ° C and mechanically stir at a speed of 55-65 rpm to gelatinize the starch The solution is transparent, and 139 grams of 20% by mass maleic acid solution is added to adjust the neutralization degree to 80%. (Nitrogen protection throughout the process)

[0062] 2) Take 90 grams of polyvinyl alcohol, heat 1-2 kilograms of distilled water in a water bath to 90-95° C., and mechanically stir at a speed of 30-50 rpm for 1-2 hours. (Nitrogen protection throughout the process)

[0063] 3) Add 100 g of hydroxypropyl methylcellulose to the tapioca starch solution after gelatinization and heat to 55-65° C. Mechanically stir at a speed of 45-55 rpm for 1-2 hours, then heat up to 65° C. (Nitrogen protection throughout the process)

[0064] 4) Add 3 grams of potassium persulfate and 8 grams of N,N-methylen...

Embodiment 3

[0073] 1) Pre-stage starch gelatinization treatment: Take 220 grams of cassava starch, 10 kg of distilled water, add 40 grams of 40% by mass sodium hydroxide to fully dissolve them at 35-40°C and mechanically stir at a speed of 55-65rpm to gelatinize the starch The solution is transparent, and 122 grams of 20% by mass maleic acid solution is added to adjust the neutralization degree to 80%. (Nitrogen protection throughout the process)

[0074] 2) Take 60 grams of polyvinyl alcohol, heat it in a water bath with 1-2 kilograms of distilled water to 90-95° C., and mechanically stir at a speed of 30-50 rpm for 1-2 hours. (Nitrogen protection throughout the process)

[0075] 3) Add 85 g of hydroxypropyl methylcellulose to the tapioca starch solution after gelatinization and heat to 55-65° C. Mechanically stir at a speed of 45-55 rpm for 1-2 hours and then heat up to 65° C. (Nitrogen protection throughout the process)

[0076] 4) Add 3 grams of potassium persulfate and 8 grams of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com