Preparation method of cellulose laminated antibacterial ultrafiltration membrane

A technology of ultrafiltration membrane and cellulose, applied in the field of ultrafiltration, can solve the problems of low flux recovery rate, low flux of ultrafiltration membrane, low antibacterial rate, etc., to achieve high flux, solve low flux, and prevent agglomeration effect of precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

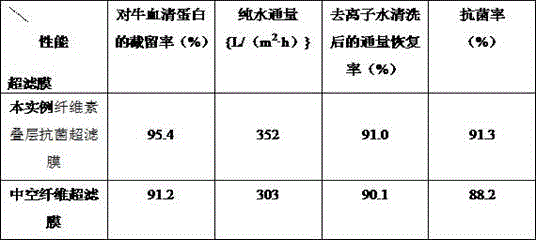

example 1

[0019] Weigh 10g of ferric chloride hexahydrate, 4.0g of ferrous chloride tetrahydrate and 300mL of deionized water, mix them and put them into a reactor, and stir them at 300r / min under nitrogen atmosphere until the solids are completely dissolved to obtain a mixed solution; Add 30mL of ammonia water with a mass fraction of 20% dropwise to the mixture at a rate of 1mL / min, stir at 300r / min for 30min, then heat to 80°C, add 0.3g of sodium citrate, keep the reaction for 1h, and cool to room temperature, and separated by a magnet to obtain a black solid, which was washed three times with deionized water and absolute ethanol in turn to obtain a magnetic Fe 3 o 4 Nanoparticles; then weigh 4g of magnetic Fe 3 o 4 Nanoparticles were added to 80mL of 5% glucose solution, dispersed by 300W ultrasonic wave for 10min, transferred to a hydrothermal reactor, reacted at 180°C for 5h, and cooled to room temperature after reaction to obtain a reaction solution; The filter residue was obta...

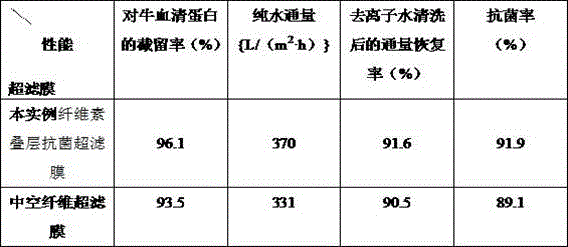

example 2

[0024] Weigh 13g of ferric chloride hexahydrate, 4.4g of ferrous chloride tetrahydrate and 400mL of deionized water, put them into the reactor after mixing, and stir at 350r / min under nitrogen atmosphere until the solids are completely dissolved to obtain a mixed solution; Add 35mL of ammonia water with a mass fraction of 20% to the mixture at a rate of 2mL / min, and stir at 350r / min for 35min, then heat to 85°C, add 0.4g of sodium citrate, keep the reaction for 2h, and cool to room temperature, and separated with a magnet to obtain a black solid, which was washed with deionized water and absolute ethanol 4 times successively to obtain a magnetic Fe 3 o 4 Nanoparticles; then weigh 5g of magnetic Fe 3 o 4 Nanoparticles were added to 90mL of 5% glucose solution, dispersed by 300W ultrasonic wave for 13min, transferred to a hydrothermal reactor, reacted at 200°C for 6h, and cooled to room temperature after reaction to obtain a reaction solution; Liquid filtration to get the fil...

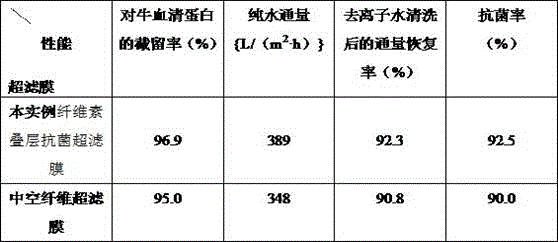

example 3

[0029] Weigh 15g of ferric chloride hexahydrate, 4.8g of ferrous chloride tetrahydrate and 500mL of deionized water, put them into the reactor after mixing, and stir at 400r / min under a nitrogen atmosphere until the solids are completely dissolved to obtain a mixed solution; Add 40mL of ammonia water with a mass fraction of 20% to the mixture at a rate of 2mL / min, and stir at 400r / min for 40min, then heat to 90°C, add 0.5g of sodium citrate, keep the reaction for 2h, and cool to room temperature, and separated with a magnet to obtain a black solid, which was washed with deionized water and absolute ethanol 5 times in turn to obtain a magnetic Fe 3 o 4 Nanoparticles; then weigh 5g of magnetic Fe 3 o 4 Nanoparticles were added to 100mL of 5% glucose solution, dispersed by 300W ultrasonic wave for 15min, transferred to a hydrothermal reactor, reacted at 220°C for 6h, and cooled to room temperature after reaction to obtain a reaction liquid; Liquid filtration to get the filter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com