Method for producing coarse particle tungsten carbide powder by tungsten-containing waste materials

A technology of tungsten carbide powder and tungsten waste, applied in the field of metallurgy, can solve the problems of low requirement of tungsten content in tungsten-containing waste, serious environmental pollution, large limitation of raw materials, etc., and achieves excellent chemical composition, remarkable economic benefits, artificial low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

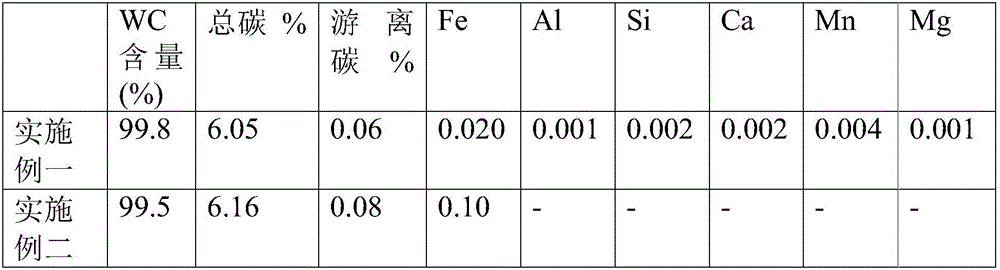

Examples

Embodiment 1

[0036] (1). Preparation: First, the tungsten-containing waste is purified by hydrochloric acid solution, and then put into a roaster for drying and roasting. The temperature is controlled at 500°C, roasted for 8 hours, and then cooled to room temperature to obtain a tungsten content of 60%. Tungsten oxide.

[0037] (2). Calculate the required ingredients according to the tungsten content in the material, and calculate according to the following weight ratio (unit: kg):

[0038] Tungsten oxide: 765

[0039] Aluminum powder: 299

[0042] Calcium carbide: 40

[0043] Carbon black: 20

[0044] (3). Put the above materials into the mixer and mix for 25 minutes until the materials are evenly mixed.

[0045] (4). Put the mixed materials into the prepared reaction furnace several times, first make the volume of the mixed materials account for one-third of the inner volume of the reaction furnace, ignite, control the tempe...

Embodiment 2

[0049] (1). Preparation: First, the tungsten-containing waste is purified by sulfuric acid solution, and then put into a roaster for drying and roasting. The temperature is controlled at 500 ° C, roasted for 8 hours, and then cooled to room temperature to obtain a tungsten content of 65%. Tungsten oxide.

[0050] (2). Calculate the required ingredients according to the tungsten content in the material, and calculate according to the following weight ratio (unit: kg):

[0051] Tungsten oxide: 765

[0052] Aluminum powder: 299

[0055] Calcium carbide: 20

[0056] Carbon black: 60

[0057] (3). Put the above materials into the mixer and mix for 30 minutes until the materials are evenly mixed.

[0058] (4). Put the mixed materials into the prepared reaction furnace several times, first make the volume of the mixed materials account for one-third of the inner volume of the reaction furnace, ignite, control the tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com