Method for preparing metal oxide/graphene-doped composite nano material based on microwave method and application

A graphene composite and nano-material technology, applied in the direction of graphene, iron oxide/iron hydroxide, iron oxide, etc., can solve the problems of long and cumbersome test periods, achieve high specific capacity, good repeatability, and improve electrical conductivity and cycle performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

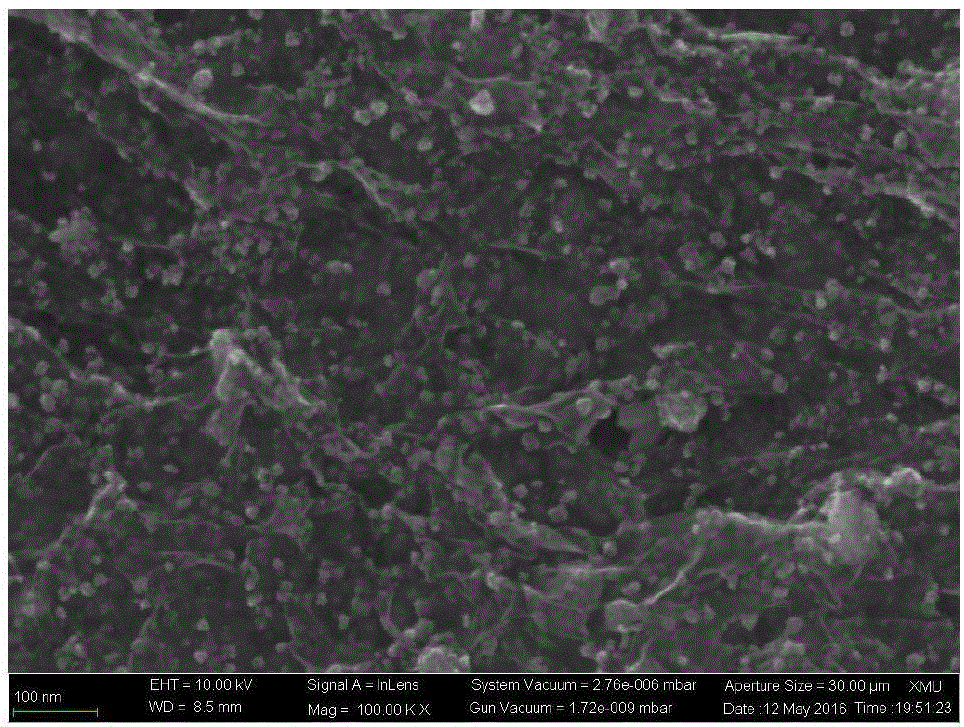

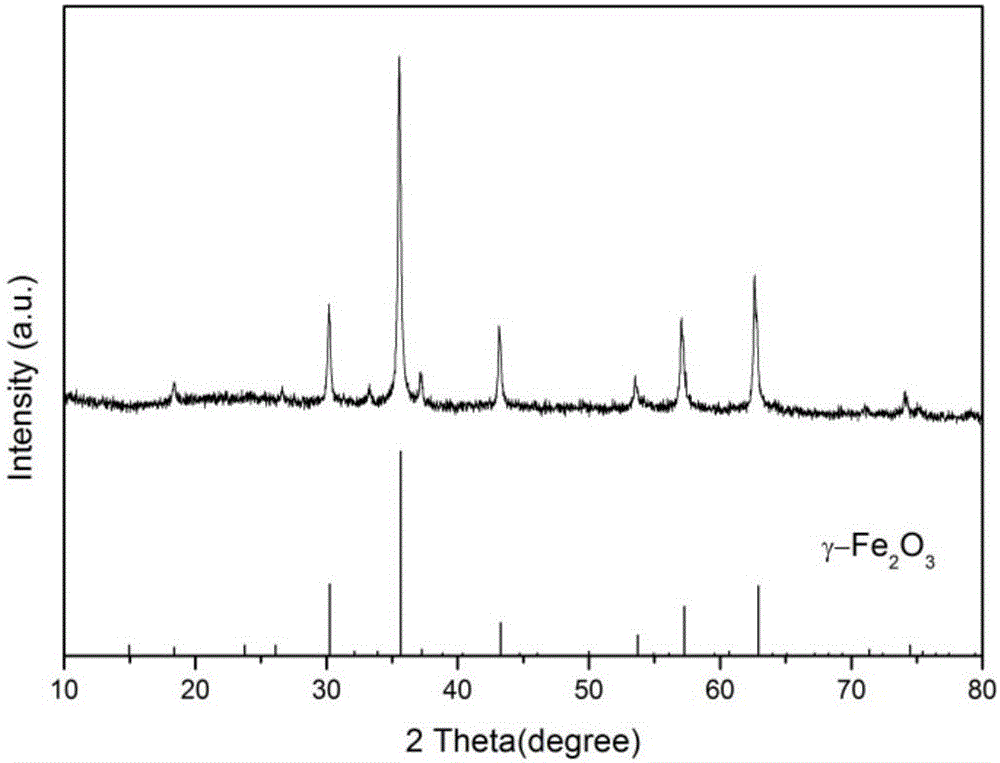

[0029] A method for synthesizing iron oxide and graphene composite material with a chromium-doped amount of 2% (atomic percent) by microwave method, comprising the following steps:

[0030] (1) Graphene oxide was prepared by the improved Hummer method, and after centrifugal washing, it was ultrasonically dispersed for 2 hours to prepare 1mgmL -1 graphene oxide aqueous solution.

[0031] (2) Configure an aqueous solution of ferrous chloride with an ion concentration of 0.02mol / L, take 100ml of the solution, add 1.2g of urea, disperse it ultrasonically for 10min, dissolve all the raw materials, add 10mL of the above graphene oxide solution, and stir magnetically for 30min , to obtain a homogeneous mixed solution.

[0032] (3) Weigh 16mg chromium nitrate nonahydrate (Cr(NO 3 ) 3 9H 2 O) Add the above solution and continue to stir to obtain a uniform tan mixed solution.

[0033] (4) Pour the mixed solution into a three-necked round-bottomed flask, and put it into a microwave ...

Embodiment 2

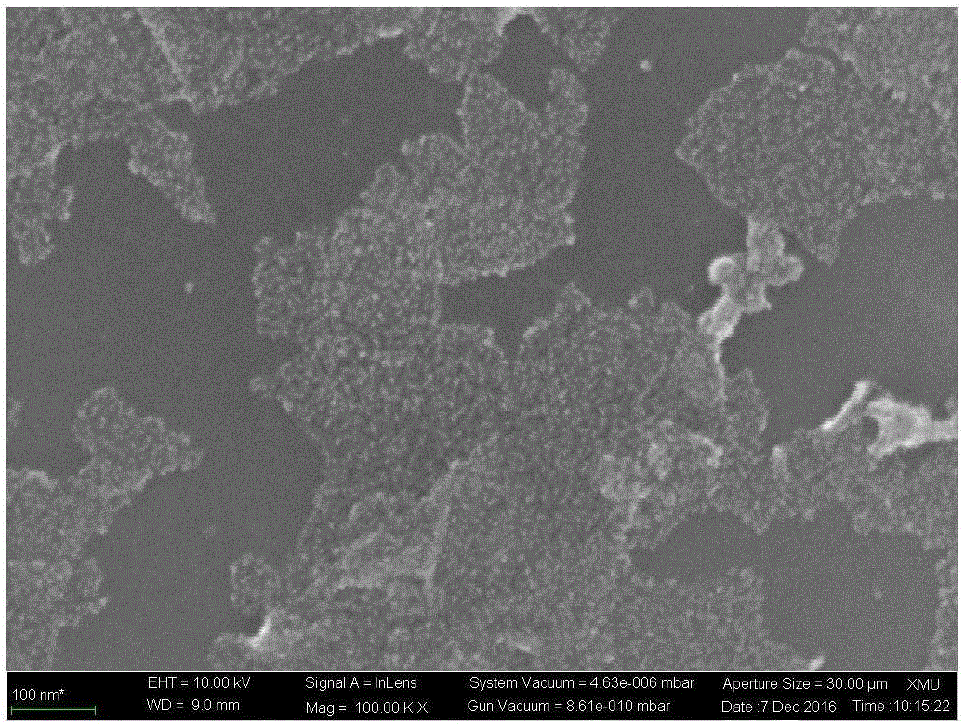

[0036] A kind of method for the iron oxide and graphene composite material of microwave method synthesis chromium doping amount 4% (atomic percentage), comprises the following steps:

[0037] (1) Graphene oxide was prepared by the improved Hummer method, and after centrifugal washing, it was ultrasonically dispersed for 2 hours to prepare 1mgmL -1 graphene oxide aqueous solution.

[0038](2) Configure an aqueous solution of ferrous chloride with an ion concentration of 0.02mol / L, take 100ml of the solution, add 1.2g of urea, disperse it ultrasonically for 10min, dissolve all the raw materials, add 10mL of the above graphene oxide solution, and stir magnetically for 30min , to obtain a homogeneous mixed solution.

[0039] (3) Weigh 32mg chromium nitrate nonahydrate (Cr(NO 3 ) 3 9H 2 O) Add the above solution and continue to stir to obtain a uniform tan mixed solution.

[0040] (4) Pour the mixed solution into a three-necked round-bottomed flask, and put it into a microwave...

Embodiment 3

[0043] A method for synthesizing tin oxide and graphene composite materials with an antimony-doped amount of 2% (atomic percent) by microwave method, comprising the following steps:

[0044] (1) Graphene oxide was prepared by the improved Hummer method, and after centrifugal washing, it was ultrasonically dispersed for 2 hours to prepare 1mgmL -1 graphene oxide aqueous solution.

[0045] (2) Configure an aqueous solution of stannous chloride with an ion concentration of 0.02mol / L, take 100ml of the solution, add 0.3g of urea, disperse it ultrasonically for 10min, dissolve all the raw materials, add 10mL of the above graphene oxide solution, and stir magnetically for 30min , to obtain a homogeneous white mixed solution.

[0046] (3) Weigh 9 mg of antimony trichloride and add to the above solution, and continue stirring for 1 h to obtain a mixed solution.

[0047] (4) Pour the mixed solution into a three-necked round-bottomed flask, and put it into a microwave catalytic synthe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com