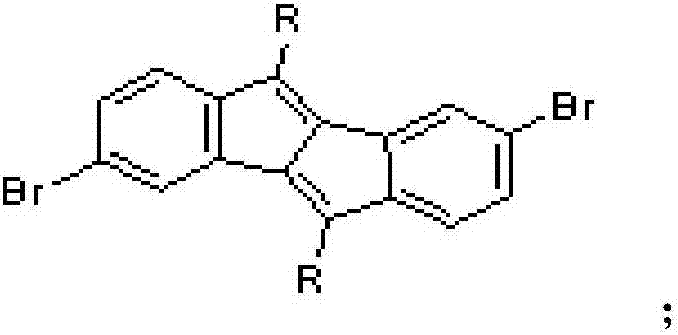

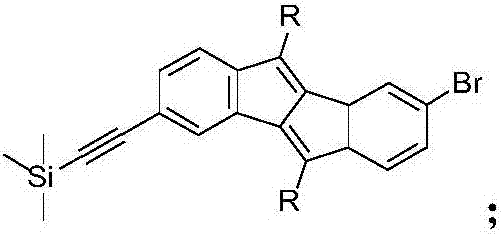

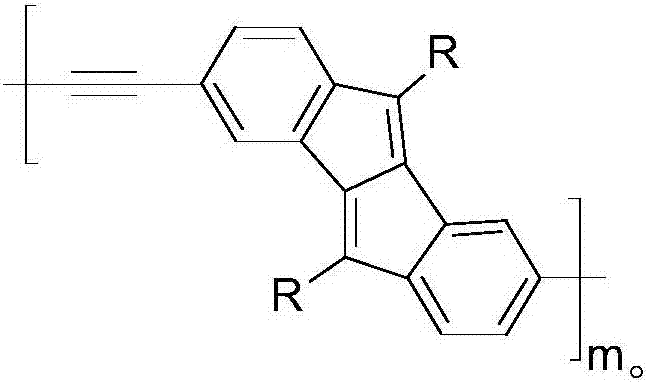

Preparation method of five-membered ring polymer used for OLED

A technology of polymer and five-membered ring, applied in the field of preparation of five-membered ring polymers, can solve the problems of short service life and low efficiency, and achieve the effects of good film-forming property, high reaction yield and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The preparation method of the five-membered ring polymer applied to OLED, the specific steps are as follows:

[0022] Step 1: Dissolve 39.0g (156.0mmol) of 2,5-dibromoaniline in 80ml of glacial acetic acid, and add 15ml of 96% sulfuric acid dropwise, dropwise add 80ml of 32g NaNO 2 Aqueous solution of urea, stirred for 1 hour, then added dropwise 60ml aqueous solution containing 18g urea, so that excess NaNO 2 Complete reaction; then 77.4g of KI aqueous solution was added dropwise, the product was extracted with dichloromethane after reacting for 1 hour, and after drying, it was chromatographed with petroleum ether to obtain 39.6g of white solid with a yield of 70%;

[0023] Step 2: get the product obtained in 21.7g (60.0mmol) step 1 and 30g (72mmol) Dissolve in 140ml of a mixture of tetrahydrofuran and triethylamine with a volume ratio of 1:1, pass through argon gas for ultrasonication, add 390mg of bistriphenylphosphine palladium dichloride and 180mg of cuprous iodi...

Embodiment 2

[0031] The preparation method of the five-membered ring polymer applied to OLED, the specific steps are as follows:

[0032] Step 1: Dissolve 13.0g (52mmol) of 2,5-dibromoaniline in 25ml of glacial acetic acid, and add 10ml of 96% sulfuric acid dropwise; dropwise add 5ml containing 10.7g NaNO 2 aqueous solution; stirred at 0°C for 1 hour, then added dropwise 20ml of aqueous solution containing 6g of urea to make excess NaNO 2 Complete reaction; Then dropwise add the aqueous solution of 25.8g (155.5mmol) KI, after reacting for 1 hour, extract product with dichloromethane, cross column with sherwood oil chromatography after drying, obtain 13.0g white solid product A, productive rate 69%;

[0033] Step 2: Get the white product A and 9.7g (36.0mmol) obtained in 10.85g step 1 Dissolve in 220ml of a mixture of tetrahydrofuran and triethylamine with a volume ratio of 1:1, pass through argon gas for ultrasonication, add 175mg of bistriphenylphosphine palladium dichloride and 82mg o...

Embodiment 3

[0041] The preparation method of the five-membered ring polymer applied to OLED, the specific steps are as follows:

[0042] Step 1: Dissolve 10.4g (41.6mmol) of 2,5-dibromoaniline in 20ml of glacial acetic acid, add 6ml of 96% sulfuric acid dropwise, and dropwise add 20ml of 8.56g NaNO 2 Aqueous solution of urea, then dropwise add 16ml of aqueous solution containing 4.8g urea, make excess NaNO 2 After complete reaction, 20.64g (124.4mmol) KI aqueous solution was added dropwise, and the product was extracted with dichloromethane. After drying, it was chromatographed with petroleum ether to obtain 10.4g white solid product A with a yield of 68.9%.

[0043] Step 2: get 9.05g (25.0mmol) of product A in step 1 and 9.87g (30.0mmol) Dissolve in 240ml of a mixture of tetrahydrofuran and triethylamine with a volume ratio of 1:1, pass through argon gas for ultrasonication, add 130mg of bistriphenylphosphine palladium dichloride, 67mg of cuprous iodide, react at room temperature, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com