A kind of polyimide nano-foam and preparation method thereof

A polyimide and nano-foam technology, applied in the field of polyimide, can solve the problems of lower glass transition temperature of materials, disordered distribution of product pores, unstable performance of various properties, etc. Polarizability, the effect of reducing the dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The invention provides a kind of preparation method of polyimide nano-foam, comprises the following steps:

[0049] a) react after diamine compound, dianhydride compound and heat unstable substance are mixed in a solvent to obtain a polyimide film; the diamine compound includes diamine containing adamantane group and polysiloxane di amine;

[0050] b) thermally decomposing the polyimide film obtained in step a) to obtain polyimide nano foam.

[0051] In the invention, the diamine compound, the dianhydride compound and the thermally unstable substance are mixed in a solvent and then reacted to obtain a polyimide film. In the present invention, the diamine compound includes adamantane group-containing diamine and polysiloxane diamine. In the present invention, the diamine containing adamantane group is preferably selected from one or more of the structures shown in formula (I-1) to formula (I-9);

[0052]

[0053]

[0054] The present invention has no special lim...

Embodiment 1

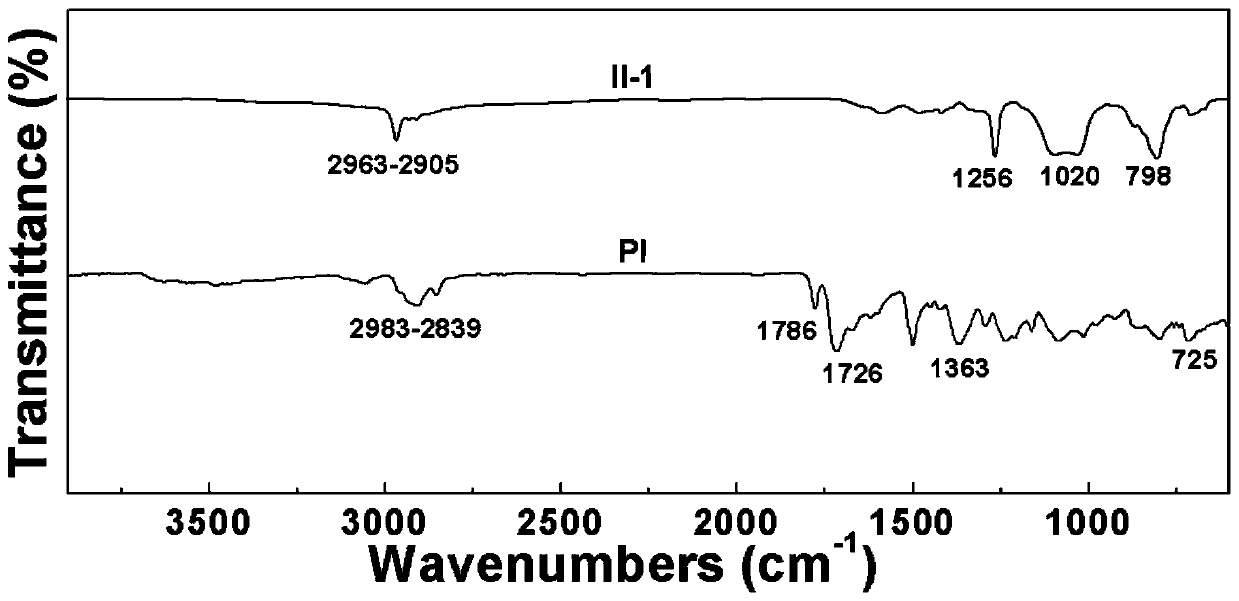

[0091] (1) 15.92g (0.05mol) of diamine containing adamantyl groups having a structure shown in formula (I-1), 10.01g (0.05mol) of 4,4'-diaminodiphenyl ether and 5.69g ( 0.0057mol) polysiloxane diamine having a structure shown in formula (II-1) with an average molecular weight of 1000g / mol was added to 250mL DMAc and 150mL DMF mixed solution, stirred and dissolved, and then 34.05g (0.1057mol)3 was added , 3', 4, 4'-benzophenone tetracarboxylic dianhydride, stirring at room temperature for 24h, to obtain a polyamic acid solution with a solid content of 15%; The thermally unstable substance with the structure shown in IV-10) is added to the above polyamic acid solution to disperse evenly to obtain a mixed solution; then the above mixed solution is cast on the substrate and cured at a humidity of 28% and a temperature of 80°C After 10 hours, a polyamic acid film was obtained; then, the polyamic acid film was raised from room temperature to 300° C. at a rate of 5° C. / min under a ni...

Embodiment 2

[0100] (1) 17.52g (0.05mol) of diamine containing adamantyl groups having a structure shown in formula (I-4), 5.00g (0.025mol) of 3,4'-diaminodiphenyl ether, 6.56g ( 0.025mol) 2,5-bis (4-aminophenyl) pyrimidine, 2.91g (0.0039mol) average molecular weight is the thermolabile substance with structure shown in formula (IV-6) and 5.69g (0.00285 mol) The polysiloxane diamine having the structure shown in formula (II-1) with an average molecular weight of 2000g / mol was added to 350mL NMP and 200mL DMF mixed solution, stirred and dissolved, and then added 33.12g (0.10675mol) 3, 3', 4, 4'-diphenyl ether tetracarboxylic dianhydride, stirred at room temperature for 24 hours to obtain a polyamic acid solution with a solid content of 11%; then cast the above polyamic acid solution on a substrate, and 20% at 100°C for 12 hours to obtain a polyamic acid film; then raise the above polyamic acid film from room temperature to 300°C at a rate of 5°C / min under nitrogen atmosphere and keep it for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com