High-flux drug detection micro-fluidic chip and application

A microfluidic chip, high-throughput technology, applied in biological testing, material inspection products, laboratory containers, etc., can solve the problem of large sample demand, achieve good detection results, and achieve high-throughput and fast results Detection analysis, the effect of strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1 Fabrication of Chips

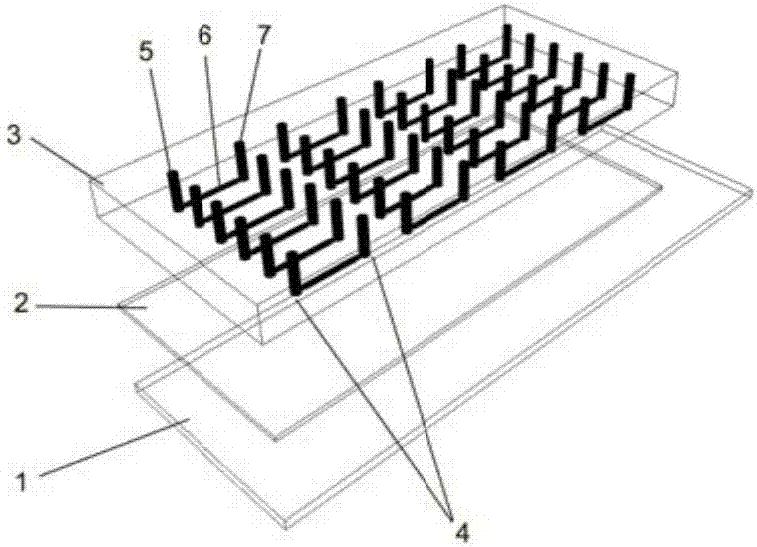

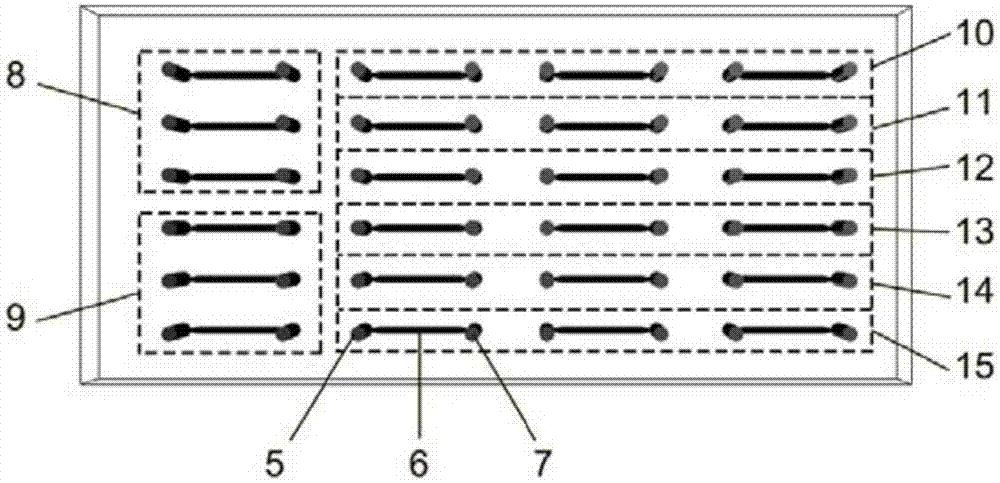

[0024] see figure 1 , a microfluidic chip capable of high-throughput drug detection. It consists of a substrate layer 1, a modification layer 2, and a reaction layer 3. The reaction layer 3 is composed of 24 identical reaction modules 4, and each reaction module 4 consists of An inlet 5, a reaction channel 6 and an outlet 7 are formed.

[0025] The substrate layer 1 and the modification layer 2 are commercially available glass slides coated with poly-lysine, preferably with a thickness of 1 mm, a width of 25 mm, and a length of 77 mm.

[0026] The reaction layer 3 is made of PDMS, and a mold with a microchannel structure is made by multi-layer soft lithography technology, and the gas-permeable PDMS is poured on the mold to be cured and demoulded. The thickness of the reaction layer 3 can be adjusted according to actual needs, preferably 3-5mm.

[0027] After the reaction layer 3 is finished, use a hole puncher with a diameter of 1mm t...

Embodiment 2

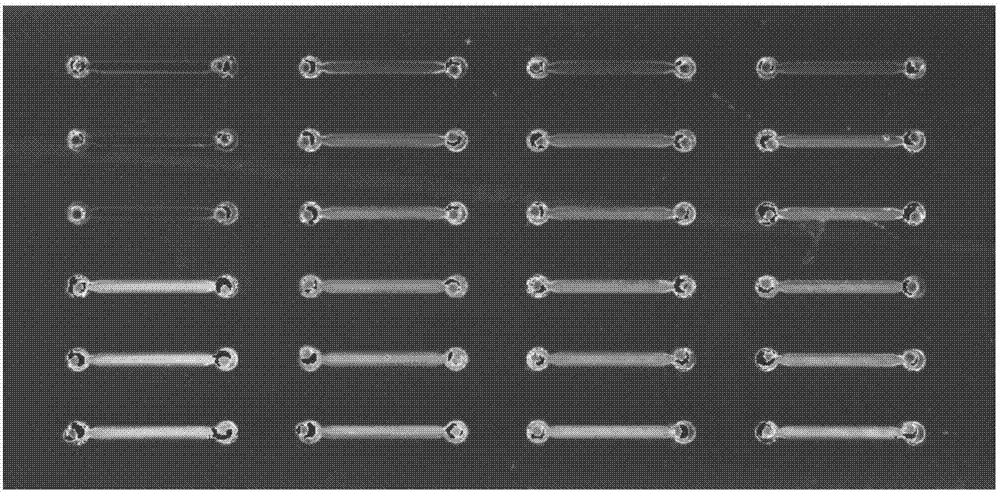

[0028] Embodiment 2 The making of methamphetamine detection standard curve (see figure 2 )

[0029] (1) Dilute the complete antigen of methamphetamine to 200 μg / mL with 0.01 mol / L, pH7.4 phosphate buffer solution (PBS), and use a pipette gun to add 3 μL from each inlet 5 into the reaction channel 6. The 3 reaction modules in the negative control area 8 are only fed with PBS. Chips were dried overnight at 37°C.

[0030] (2) Add Tween-20 with a volume fraction of 0.05% in PBS to prepare a PBST coating solution. Add 3 μL of the coating solution from each inlet 5 into the reaction channel 6 with a pipette gun. Put the chips into a wet box and keep at 37°C for 1h.

[0031] (3) 15 µL of PBST was added to each inlet 5, and PBST was drawn out from the outlet 7 using a syringe pump having a suction function.

[0032] (4) Use PBST to configure 2.4 μg / mL fluorescent latex microsphere solution with methamphetamine antibody.

[0033] (5) Use the mixture prepared in (4) to gradiently...

Embodiment 3

[0037] Example 3 Detection of methamphetamine

[0038](1) Dilute the complete antigen of methamphetamine to 200 μg / mL with 0.01 mol / L, pH7.4 PBS, and add 3 μL from each inlet 5 into the reaction channel 6 using a pipette gun. Chips were dried overnight at 37°C.

[0039] (2) Add Tween-20 with a volume fraction of 0.05% in PBS to prepare a PBST coating solution. Add 3 μL of the coating solution from each inlet 5 into the reaction channel 6 with a pipette gun. Put the chips into a wet box and keep at 37°C for 1h.

[0040] (3) 15 µL of PBST was added to each inlet 5, and PBST was drawn out from the outlet 7 using a syringe pump having a suction function.

[0041] (4) Use PBST to configure 2.4 μg / mL fluorescent latex microsphere solution with methamphetamine antibody.

[0042] (5) Use the mixture prepared in (4) to mix with the methamphetamine sample.

[0043] (6) Add the methamphetamine sample obtained in (5) to the inlet 5, and draw it into the reaction channel 6 from the ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com