Processing method for crystal patterns of titanium product

A processing method and product technology, applied to the craft and decorative arts for producing decorative surface effects, can solve the problems of inability to obtain crystal patterns, inability to reflect artistic craftsmanship, and single decorative effect, so as to achieve process parameters that are easy to control and process The effect of low cost and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for processing crystal patterns of titanium products, specifically comprising the following three steps:

[0036] The first step: heat treatment of titanium products under vacuum conditions, including the following steps:

[0037] Step 1.1, vacuum treatment, specifically: in vacuum (vacuum degree is 6 * 10 -2 Pa) conditions, the titanium product is raised from room temperature to 1050°C for 2 hours, and then kept for 2 hours;

[0038] Step 1.2, cooling treatment, specifically: filling with argon (the pressure when backfilling with argon during cooling is set to 2.3 bar), and cooling the titanium product to 60° C. in 3 hours to obtain a heat-treated titanium product.

[0039] Step 2: Grinding the titanium products after heat treatment, specifically: use the abrasive tools of 400#, 800# and 1200# to carry out rough grinding, medium grinding and fine grinding on the titanium products in turn, and polish to bright (rough degree Ra<0.1μm).

[0040] The third step...

Embodiment 2-3

[0043] The difference between embodiment 2-3 and embodiment 1 lies in table 1.

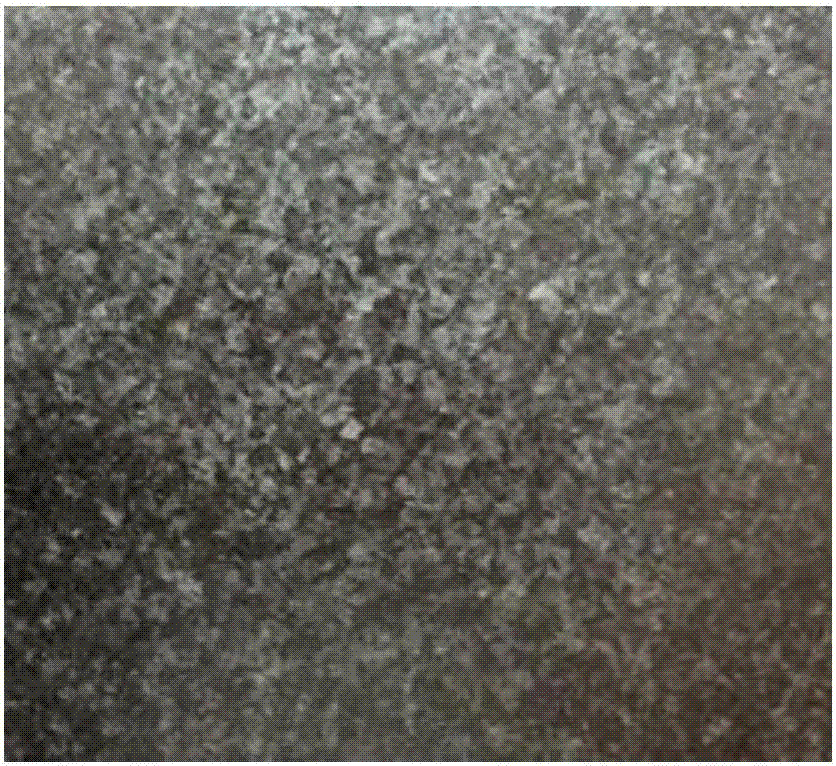

[0044] The effect diagrams of the titanium products with patterns obtained in Examples 2-3 are shown in detail respectively image 3 with Figure 4 .

[0045] Table 1 embodiment 1-3 and the process parameter comparison table of comparative example 1-2

[0046]

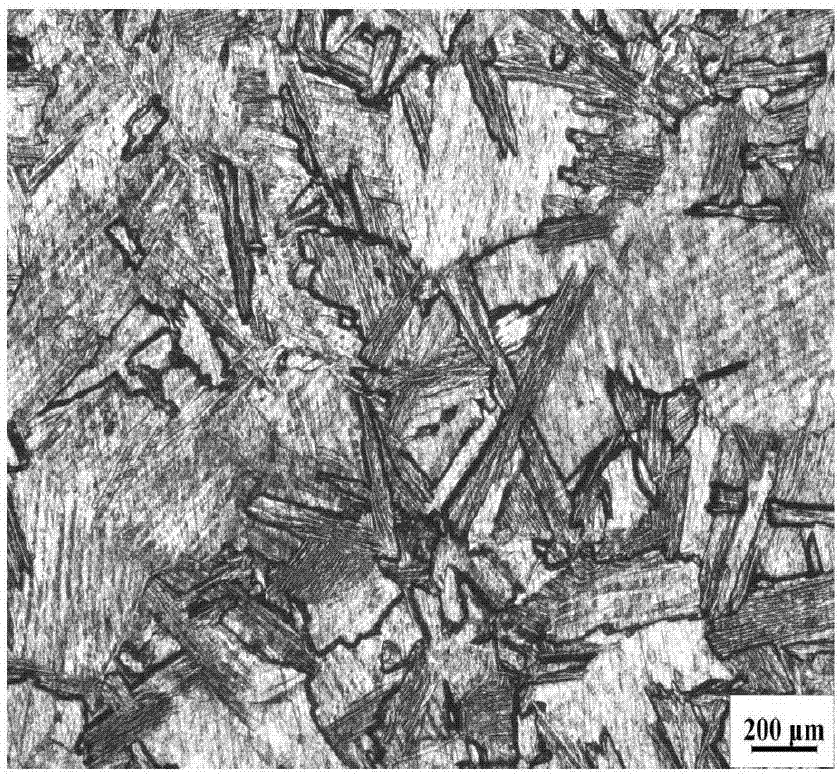

[0047] Combining Table 1 and Figure 1-Figure 6 It can be seen that:

[0048] The combination of Embodiment 1, Embodiment 2 and Embodiment 3: the heat treatment temperature is 1000°C-1200°C, which can make the surface of titanium products obtain abnormally coarse grains (up to 1-5mm), and then grind and pickle Process, the grain boundary is corroded, so that the grain boundary between the grains is clear, and the effect is visible to the naked eye. The crystal flower effect with metallic luster can be seen with the naked eye, and the product yield is high. Different heat treatment temperatures result in different coarse grain sizes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com