Decrement processing system and method for excrement sources of large and medium-sized live pig farms

A treatment system and farm technology, which is applied in the field of manure source reduction treatment system for large and medium-sized pig farms, can solve the problems of large sewage production, high operating costs, and inability to absorb manure in the surrounding matching farmland, so as to achieve reduction Disposal cost, strong antifouling and self-cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

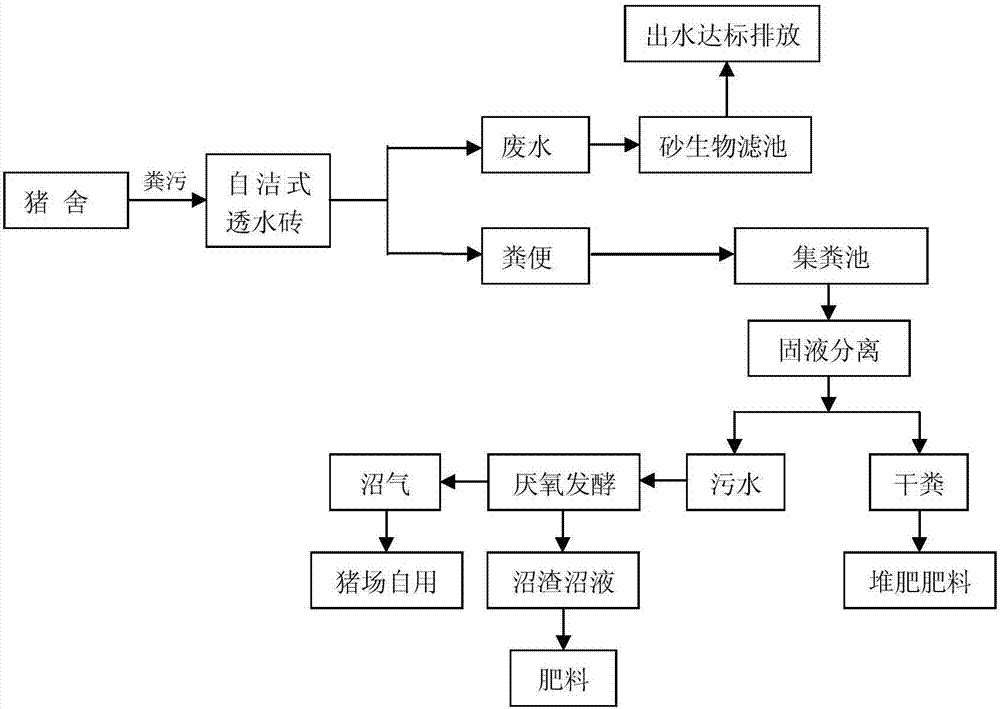

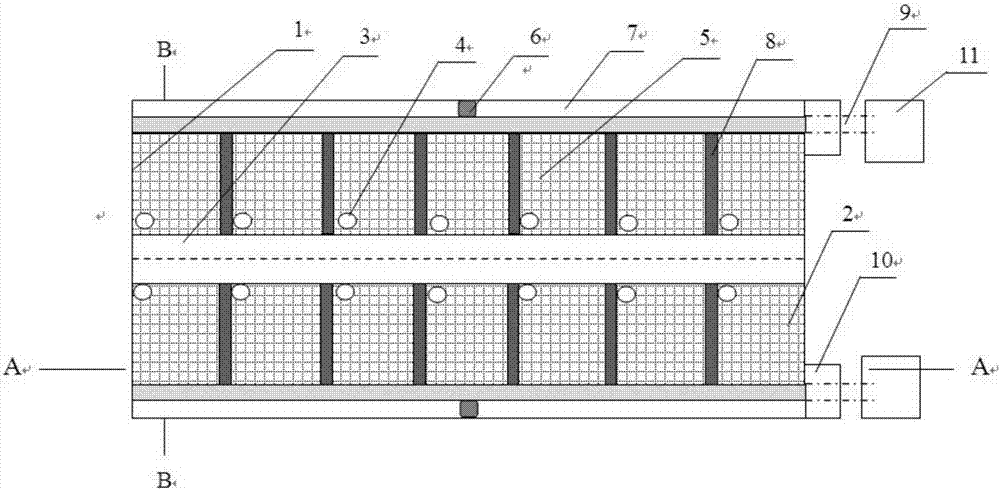

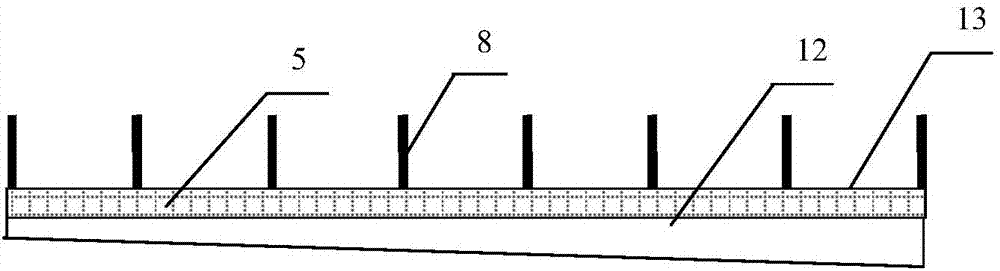

[0053] A source reduction treatment system for large and medium-sized pig farms, comprising a pig house 1, a waste water collection pipe 9, a feces collection channel 7, a sump 11 and a septic tank 10, the pig house 1 passes through a pig house partition wall 8 The pigsty 2 is spaced apart, and the pig house ground 13 is provided with water collecting grooves 12 at intervals, and the water collecting grooves 12 are arranged along the length direction of the pig house 1, and the length of the water collecting grooves 12 is the same as that of the pig house 1, and The adjacent catchment grooves 12 are parallel to each other, the catchment grooves 12 are connected with the waste water collection pipe 9, the waste water collection pipe 9 is connected with the sump 11, and the sump 11 is arranged at one end of the pig house 1; the pig house floor 13 is a cement floor , the top of pig house floor 13 is laid with self-cleaning type permeable brick 5, and self-cleaning type permeable b...

Embodiment 2

[0062] Utilize the method for reducing the amount of manure source treatment system of embodiment 1 to handle 20,000 pig farm manures in stock, the steps are as follows:

[0063] Pigs move on the self-cleaning permeable brick 5, and the waste water in the manure such as feces and urine, water spilled in the drinking process is filtered through the self-cleaning permeable brick 5, collected in the water collection groove 12, and passed through the waste water collection pipe 9 , and finally collect into the sump 11; the feces after filtering sewage are left on the self-cleaning permeable brick 5, and the feces enter the feces collection channel 7 through manual cleaning or water flushing. The manure plate 6 is scraped into the cesspool 10; the feces in the cesspool 10 are separated from solid and liquid, and the small amount of sewage produced is anaerobically fermented, and the biogas generated is used in pig farms, and the biogas residue and biogas slurry are used as farmland ...

Embodiment 3

[0070] Utilize the method for the manure source reduction treatment system of embodiment 1 to process 40,000 pig farm manures in stock, the steps are as follows:

[0071] Pigs move on the self-cleaning permeable brick 5, and the waste water in the manure such as feces and urine, water spilled in the drinking process is filtered through the self-cleaning permeable brick 5, collected in the water collection groove 12, and passed through the waste water collection pipe 9 , and finally collect into the sump 11; the feces after filtering sewage are left on the self-cleaning permeable brick 5, and the feces enter the feces collection channel 7 through manual cleaning or water flushing. The dung plate 6 is scraped into the cesspool 10; the feces in the cesspool 10 are separated from solid and liquid, and the small amount of sewage generated is anaerobically fermented, and the biogas generated is used in pig farms, and biogas residue and biogas slurry are used as farmland organic ferti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com