Biodegradable polylactic acid composite as well as preparation method and application thereof

A composite material and biodegradable technology, applied in the field of polylactic acid composite materials, can solve the problems that hinder the application range of polylactic acid and agricultural waste composite materials, poor impact resistance, etc., and achieve the effect of simple processing, low cost and good hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

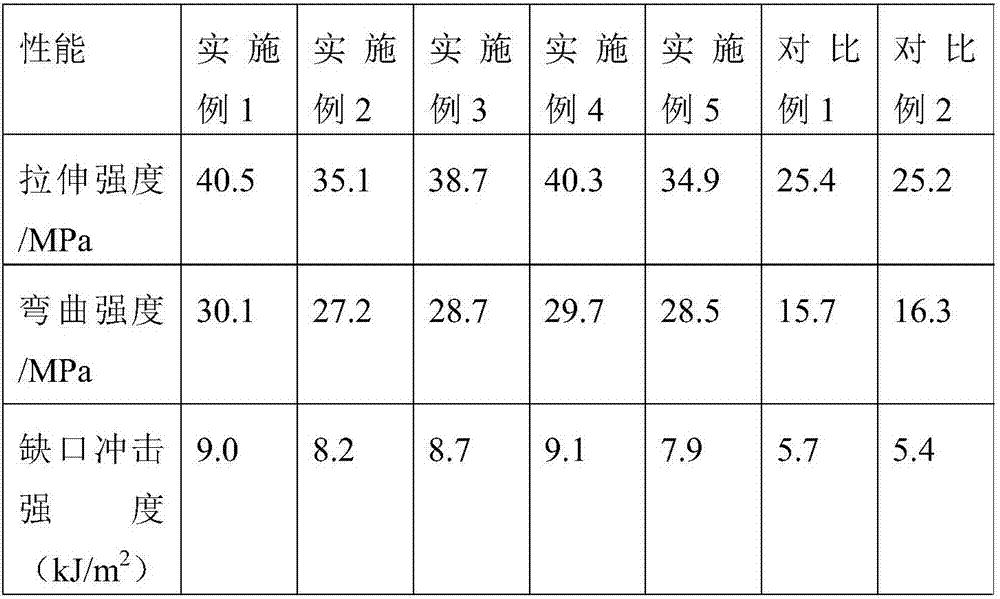

Examples

Embodiment 1

[0038] A biodegradable polylactic acid composite material, comprising the following raw materials by weight percentage:

[0039] Polylactic acid 50%,

[0040] Wheat Straw 20%,

[0041] Nano Calcium Carbonate 30%.

[0042] The preparation method of above-mentioned biodegradable polylactic acid composite material, comprises the steps:

[0043] (1) Cleaning the wheat straw, removing silt and rot, drying and pulverizing, and passing the obtained powder through a 60-mesh sieve, and then drying in a dryer until the moisture content is 1%-3%;

[0044] (2) drying the wheat straw and polylactic acid treated in step (1) at 80-90° C. for 3-4 hours, and controlling the humidity below 250 ppm to obtain a mixture;

[0045] (3) Extrude and granulate the mixture obtained through step (2) and nano-calcium carbonate in a twin-screw extruder, wherein the extrusion temperature is 175-200°C, the screw speed is 300r / min, and the length of the screw The diameter ratio is 40:1, forming granular s...

Embodiment 2

[0049] A biodegradable polylactic acid composite material, comprising the following raw materials by weight percentage:

[0050] Polylactic acid 60%,

[0051] Corn stover 15%,

[0052] Nano Calcium Carbonate 25%.

[0053] The preparation method of above-mentioned biodegradable polylactic acid composite material, comprises the steps:

[0054] (1) Clean up the corn stalks, remove the silt and rot, dry them and pulverize them, pass the obtained powder through a 60-mesh sieve, and then put them into a dryer to dry until the moisture content is 1%-3%;

[0055] (2) drying the corn stalks and polylactic acid treated in step (1) at 80-90° C. for 3-4 hours, and controlling the humidity below 250 ppm to obtain a mixture;

[0056] (3) Extrude and granulate the mixture obtained through step (2) and nano-calcium carbonate in a twin-screw extruder, wherein the extrusion temperature is 175-200°C, the screw speed is 300r / min, and the length of the screw The diameter ratio is 40:1, forming...

Embodiment 3

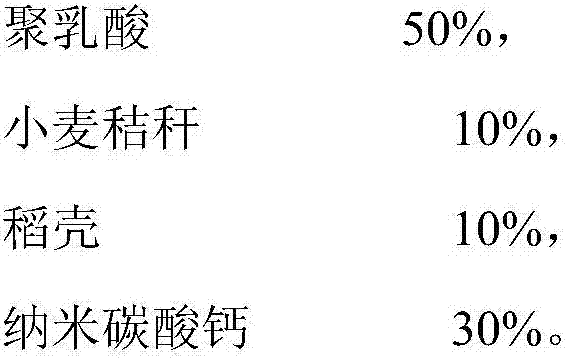

[0059] A biodegradable polylactic acid composite material, comprising the following raw materials by weight percentage:

[0060] Polylactic acid 40%,

[0061] Rice Bran 30%,

[0062]Nano Calcium Carbonate 30%.

[0063] The preparation method of above-mentioned biodegradable polylactic acid composite material, comprises the steps:

[0064] (1) Cleaning the rice bran, removing silt and rot, drying and pulverizing, passing the obtained powder through a 60-mesh sieve, and then putting it into a dryer to dry until the moisture content is 1%-3%;

[0065] (2) drying the rice bran and polylactic acid treated in step (1) at 80-90° C. for 3-4 hours, and controlling the humidity below 250 ppm to obtain a mixture;

[0066] (3) Extrude and granulate the mixture obtained through step (2) and nano-calcium carbonate in a twin-screw extruder, wherein the extrusion temperature is 175-200°C, the screw speed is 400r / min, and the length of the screw The diameter ratio is 50:1, forming granular...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com