Renewable high-efficiency formaldehyde removal material and preparation method thereof

A formaldehyde removal and high-efficiency technology, applied in separation methods, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as desorption, secondary pollution, limiting material reaction efficiency, etc., to promote catalytic reaction activity, no irritating odor , the effect of improving conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The renewable high-efficiency formaldehyde removal material involved in the present invention mainly includes ultra-thin manganese dioxide nanosheets in δ crystal form, modified sepiolite and molybdenum carbide nanoparticles, and is an environmentally friendly and non-toxic powder catalytic material. The preparation method comprises the following steps:

[0023] Step 1: Mix 3-5 mL of tetramethylammonium hydroxide (TMA OH) with 2-4 mL of 30% H 2 o 2 The solutions were mixed to obtain solution A;

[0024] Step 2: Dissolving 50-65 g of manganese chloride tetrahydrate in 25 mL of ultrapure water to prepare solution B;

[0025] Step 3: Add solution A to solution B dropwise, and apply strong stirring during the addition and mixing process; then, ultrasonically disperse for 3-5 minutes, and continue stirring at room temperature for 80 minutes to obtain dark brown ultrathin MnO 2 Colloidal suspension of nanosheets;

Embodiment

[0031] Mix 3 mL of tetramethylammonium hydroxide (TMA·OH) with 4 mL of 30% HO 2 o 2 Mix to make Solution A. Solution B was prepared by dissolving 56 g of manganese chloride tetrahydrate in 25 mL of ultrapure water. Add solution A to solution B dropwise, and apply vigorous stirring during the addition and mixing process. Subsequently, ultrasonic dispersion was performed for 5 min, and stirring was continued for 80 min at room temperature to obtain ultrathin MnO 2 Colloidal suspension of nanosheets. Dissolve alkaline sepiolite and nano-molybdenum carbide (MoC) in a solution with a volume ratio of ethanol and water (1:9), and add MnO 2 Colloidal suspension, the control temperature is 80 ℃, stirred and reacted for 8 h, the obtained reaction solution is centrifuged, and the obtained precipitate is dried at a control temperature of 110 ℃, and the ultra-thin MnO loaded 2 High-efficiency formaldehyde-scavenging materials of nanosheets.

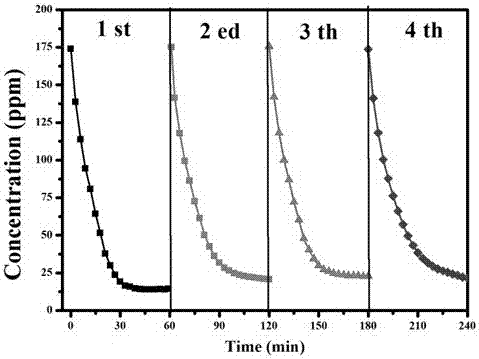

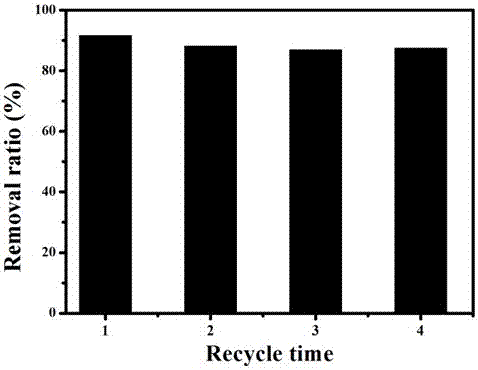

[0032] Inject the air above the formaldeh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com