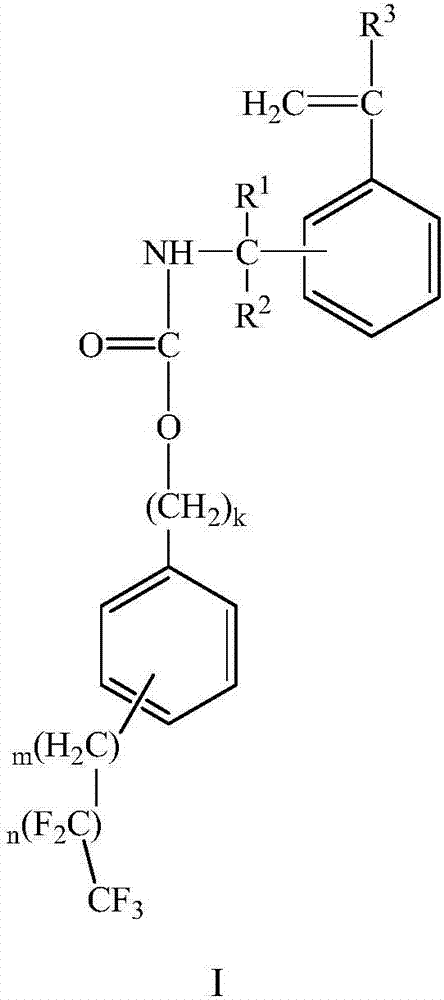

Hydrophobic monomers and high-molecular polymers, and preparation method of hydrophobic monomers, preparation method of high-molecular polymers and application of high-molecular polymers

A technology of high molecular polymers and hydrophobic monomers, which is used in the preparation of organic compounds, the preparation of carbamate derivatives, the composition of drilling holes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

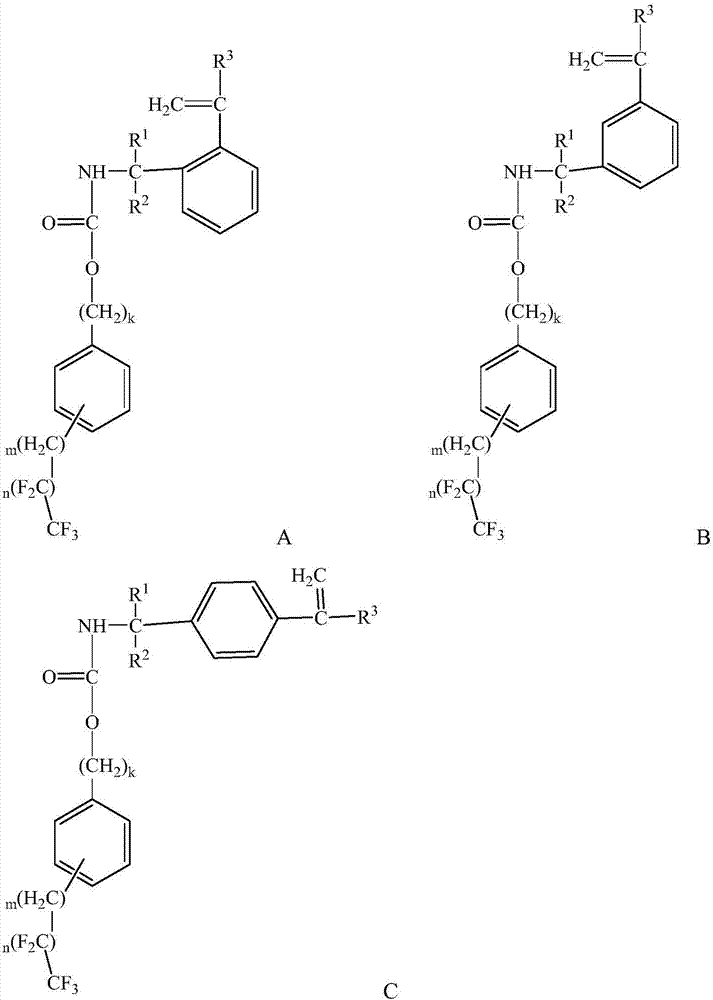

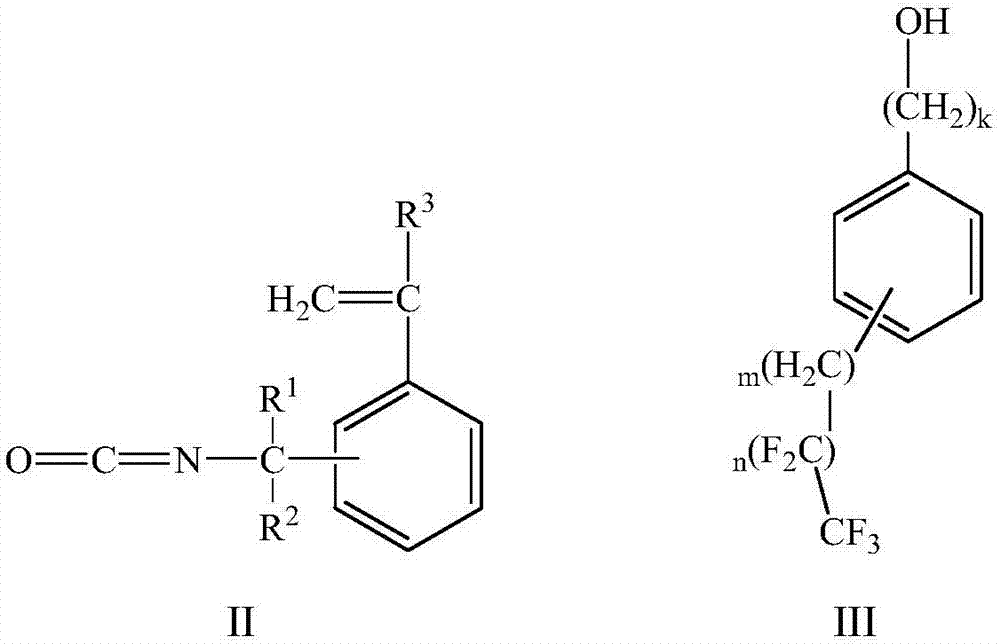

[0047] The synthesis of embodiment 1 hydrophobic monomer

[0048] The synthetic route is as follows:

[0049]

[0050] Add 350 mL of acetone and 45.42 g of 4-tridecafluorooctylbenzyl alcohol into a dry three-neck flask equipped with a stirrer, condenser and dropping funnel, and stir until the 4-tridecafluorooctylbenzyl alcohol is fully dissolved. The water bath was heated to a temperature of 50°C, and vacuum was applied for 2.5 hours to remove moisture. Under nitrogen protection, 0.0225 g of dibutyltin dilaurate was added. 22.54 g of 3-isopropyl-dimethylbenzyl isocyanate in the dropping funnel was dropped into a three-necked flask, reacted for 12 hours, and distilled under reduced pressure to remove acetone, and the crude product of the target molecule was obtained. The crude product was rinsed with chloroform three times, and placed in an oven at 65° C. until constant weight to obtain the target product with a yield of 79%.

Embodiment 2

[0052] With 42.64 acrylamide, 18.80g sodium acrylate, 11.11g N-vinylpyrrolidone, 45.85g 2-acrylamide-2-sodium methylpropanesulfonate, 3.61g hydrophobic monomer prepared in Example 1, 38.32g octadecane Sodium sulfonate and 1100 mL of distilled water were placed in a reactor, and stirred evenly until the water-soluble monomer was completely dissolved, and the hydrophobic monomer was solubilized in the micelles of sodium octadecylsulfonate to obtain a pre-reaction system. Nitrogen is continuously passed into the reaction system to eliminate oxygen in the reaction system and provide an oxygen-free reaction environment. Add 0.04g 2-hydroxy-4'-(2-hydroxyethoxy)-2-methylpropiophenone and 1.5g disodium edetate, control the temperature of the water bath to 20°C-30°C, and keep stirring Put it in a 100W high-pressure mercury lamp with the main wave of ultraviolet light at 365nm, polymerize for 3.0 hours, and let it stand for aging for 2 hours to obtain a crude colloidal product. The cru...

Embodiment 3

[0054] 59.47gN, N-dimethylacrylamide, 9.41g sodium acrylate, 5.56gN-vinylpyrrolidone, 51.55g p-styrene sodium sulfonate, 13.1g hydrophobic monomer prepared in Example 1, 52.15g dodecyl Sodium sulfonate and 678.06 mL of distilled water were placed in the reactor, and stirred evenly until the water-soluble monomer was completely dissolved, and the hydrophobic monomer was solubilized in the micelles of sodium dodecylsulfonate to obtain a pre-reaction system. Nitrogen is continuously passed into the reaction system to eliminate oxygen in the reaction system and provide an oxygen-free reaction environment. Add 0.0556g of 2-hydroxy-2-methyl-1-phenylacetone and 0.88g of disodium ethylenediaminetetraacetate, control the temperature of the water bath to 20°C-30°C, and place it at 200W under continuous stirring conditions, and the main wave of ultraviolet light Polymerize under a high-pressure mercury lamp of 365 nm for 2 hours, and leave to mature for 2 hours to obtain a crude colloida...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com