A self-cleaning UV-cured transparent heat-insulating coating and its preparation method

A heat-insulating coating and ultraviolet light technology, applied in polyether coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve problems such as flammability, poor leveling, and poor yellowing resistance, and improve construction performance and use safety , the effect of low surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

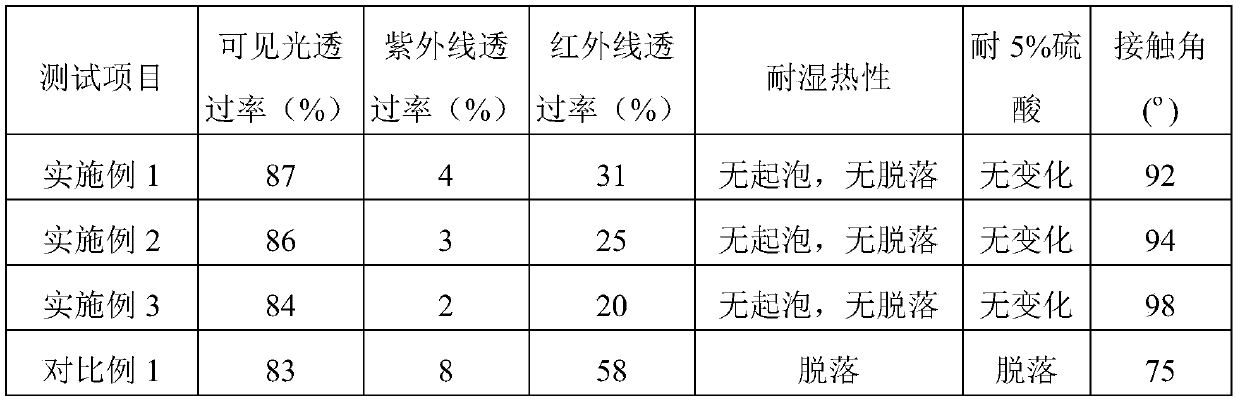

Embodiment 1

[0024] Add 0.5 parts by mass of nano-ATO and 1.5 parts by mass of nano-TiO to a four-necked flask equipped with a stirring device, a thermometer and a condenser tube 2 , a mixed solution of 50 parts by mass of methanol and 0.5 parts by mass of a silane coupling agent (KH-570), heated to 50°C, and refluxed for 12h. After cooling to room temperature, the product was transferred to a rotary evaporator, and methanol was distilled off by heating. Add trifluorooctyl methacrylate and ultrasonically disperse for 1 hour to prepare a modified nano functional element / fluorine-containing reactive diluent mixed slurry with a solid content of 8%.

[0025] 10 mass parts of epoxy acrylic acid oligomer, 1 mass part of modified nano functional element / fluorine-containing active diluent mixed slurry prepared above, 2 mass parts of ethylene glycol dimethacrylate, trimethylolpropane 3 parts by mass of trimethacrylate, mix uniformly, add 0.2 parts by mass of photoinitiator 1173, 0.1 parts by mass ...

Embodiment 2

[0027] Add 1.0 parts by mass of nano-ATO and 1.0 parts by mass of nano-TiO to a four-necked flask equipped with a stirring device, a thermometer and a condenser tube 2 , a mixed solution of 50 parts by mass of methanol and 1.0 parts by mass of a silane coupling agent (KH-570), heated to 60°C, and refluxed for 18h. After cooling to room temperature, the product was transferred to a rotary evaporator, and methanol was distilled off by heating. Add hexafluorobutyl methacrylate and ultrasonically disperse for 1.5 hours to prepare a modified nano functional element / fluorine-containing reactive diluent mixed slurry with a solid content of 10%.

[0028] Mix 10 parts by mass of polyurethane acrylic acid oligomer, 3 parts by mass of the modified nano-functional element / fluorine-containing active diluent mixed slurry prepared above, and 3 parts by mass of diethylene glycol dimethacrylate, and mix uniformly. Add 0.8 parts by mass of UV photoinitiator 907, 0.2 parts by mass of leveling a...

Embodiment 3

[0030] Add 1.5 parts by mass of nano-ATO and 0.5 parts by mass of nano-TiO to a four-necked flask equipped with a stirring device, a thermometer and a condenser tube 2 , a mixed solution of 50 parts by mass of methanol and 1.5 parts by mass of silane coupling agent (KH-570), heated to 70°C, and refluxed for 24h. After cooling to room temperature, the product was transferred to a rotary evaporator, and methanol was distilled off by heating. Add trifluoroethyl methacrylate and ultrasonically disperse for 2 hours to prepare a modified nano functional element / fluorine-containing reactive diluent mixed slurry with a solid content of 15%.

[0031] Mix 10 parts by mass of polyether acrylic acid oligomer, 5 parts by mass of the modified nano functional element / fluorine-containing active diluent mixed slurry prepared above, and 1 part by mass of 1,4-butanediol dimethacrylate. Evenly, add 1.5 parts by mass of photoinitiator BP, 0.3 parts by mass of leveling agent ( Rad 2100) and 0.3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com