Preparation method of mesoporous silica/titania nanotube array composite

A technology of mesoporous silica and nanotube arrays, applied in metal material coating process, electrolytic coating, liquid chemical plating, etc., can solve the problems such as unable to fully meet clinical needs, difficult to form bone bonding, etc. Facilitates growth and adhesion, promotes bioavailability, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

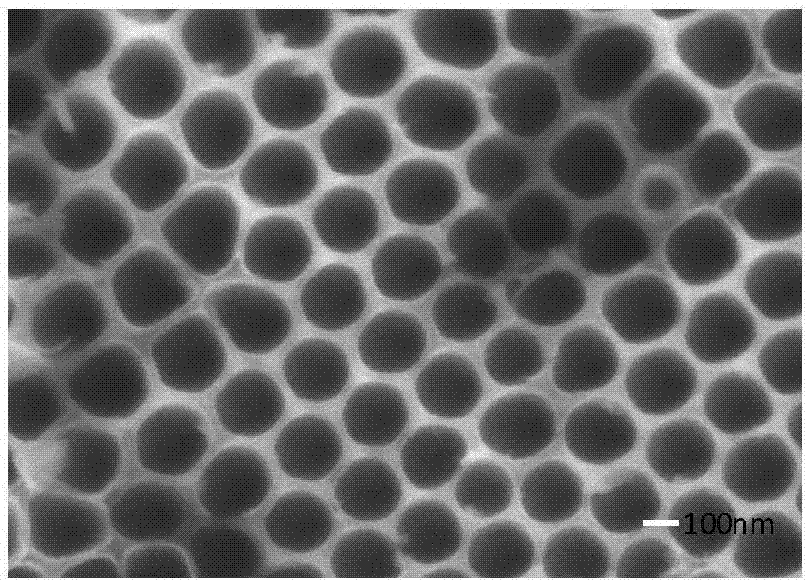

[0025] With titanium metal as the substrate, it was polished to smooth with metallographic sandpaper, ultrasonically cleaned in acetone and cleaned in 4wt%HF-5mol / LHNO 3 etched in a mixed acid solution, rinsed with distilled water, ultrasonicated, and dried at 50°C to obtain the treated titanium sheet. With the pretreated titanium sheet as the anode and the platinum sheet as the cathode, 0.50wt% NH 4 +10wt%H 2 O+glycerol is the electrolyte solution, in which the mass ratio of glycerol (glycerol) to water is 9:1. After anodizing at 60V for 24 hours, take it out, rinse it with distilled water, and dry it in the air to get titanium dioxide nanoparticles. tube array, the microscopic topography is shown in figure 1 As shown, the nanotubes are closely arranged and regular, and the diameter of the tube is about 210nm.

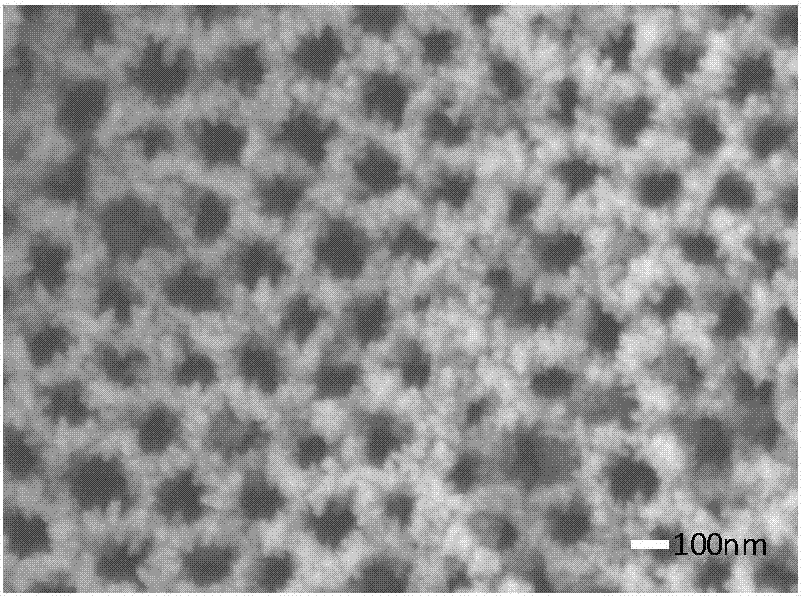

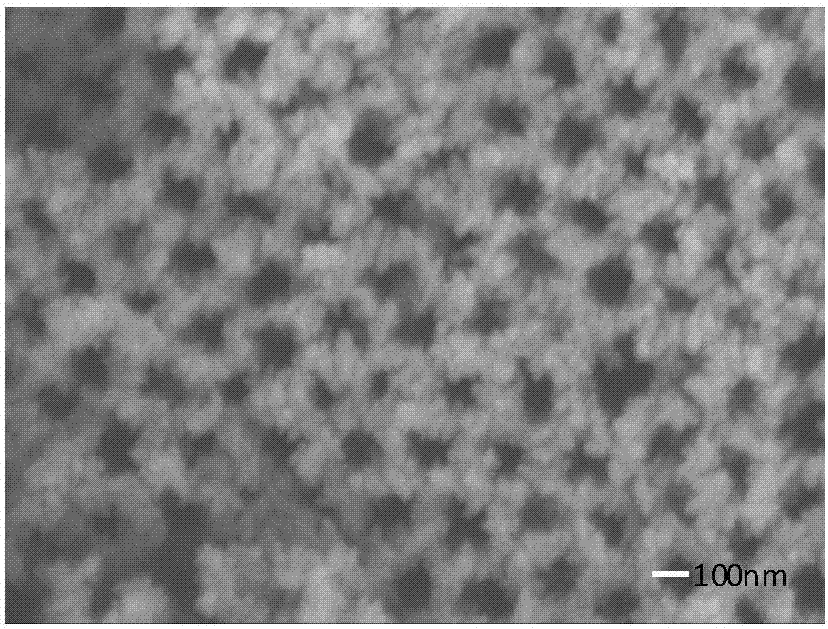

[0026] Dissolve 5.60mmol of dodecyltrimethylammonium bromide in 122ml of distilled water, then add 8g of 25wt% NH 3 ·H 2 O, stir for 10 min. Add 10.0 g tetraeth...

Embodiment 2

[0029] With titanium metal as the substrate, it was polished to smooth with metallographic sandpaper, ultrasonically cleaned in acetone and cleaned in 4wt%HF-5mol / LHNO 3 etched in a mixed acid solution, rinsed with distilled water, ultrasonicated, and dried at 50°C. With the pretreated titanium sheet as the anode and the platinum sheet as the cathode, 0.50wt% NH 4 F+10wt%H 2 O+glycerol is the electrolyte solution, in which the mass ratio of glycerol (glycerol) to water is 9:1. After anodizing at 60V for 24 hours, take it out, rinse it with distilled water, and dry it in the air to get titanium dioxide nanoparticles. tube array, the microscopic topography is shown in figure 1 As shown, the nanotubes are closely arranged and regular, and the diameter of the tube is about 210nm.

[0030]Dissolve 5.60mmol of cetyltrimethylammonium bromide in 122ml of distilled water, then add 8g of 25wt%NH 3 ·H 2 O, stir for 10 min. Add 10.0 g tetraethyl orthosilicate (TEOS) while stirring, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com