PERC crystal silicon solar battery positive silver paste and preparation method therefor

A solar cell and silver paste technology, which is applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., can solve problems such as increased contact resistance and reduced photoelectric conversion efficiency, and reduce sintering The effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The composition of the positive silver conductive paste in this embodiment and its weight percentage: silver powder 85%, glass powder 3%, organic carrier 8%, Ce 2 O 3 0.02%, La 2 O 3 0.05%, BYK180 0.2%, the rest is solvent. The particle size of the silver powder is 1~3.5 microns, and the tap density is 4~6g / m 3 Spherical silver powder; glass powder is PbO-TeO 2 Series of glass powder with a particle size of 0.5-3 microns.

[0027] Preparation of organic carrier: rosin 1%, cellulose acetate 2%, polyester 5%, dimethyl phthalate 30%, butyl carbitol acetate 30%, alcohol ester twelve 30%, at 80°C Dissolve for 2 hours to obtain a uniform organic carrier;

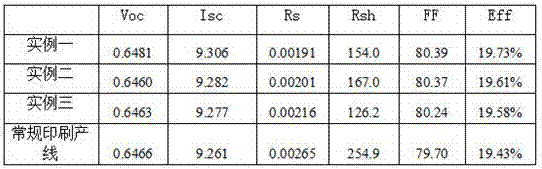

[0028] Weigh 85% silver powder, 3% glass powder, 8% organic carrier, Ce 2 O 3 0.02%, La 2 O 3 0.05%, BYK180 0.2%, mix uniformly in a planetary mixer or other mixers, and then disperse it to less than 10μm on a three-roller to make a crystalline silicon solar cell positive silver paste. The positive silver paste of the cryst...

Embodiment 2

[0031] The composition and weight percentage of the positive silver conductive paste of this embodiment: 75% silver powder, 5% glass powder, 10% organic carrier, Nd 2 O 3 0.02%, Eu 0.02%, the rest is solvent. The particle size of the silver powder is 1.5~3.5 microns, and the tap density is 4~6g / m 3 Spherical silver powder; glass powder is PbO-TeO 2 Series of glass powder with a particle size of 0.5-3 microns.

[0032] Preparation of organic vehicle: ethyl cellulose 3%, polyamide 2%, cellulose acetate 10%, terpineol 20%, propylene glycol butyl ether 20%, alcohol ester twelve 30%, dissolved at 80°C for 2 hours, Obtain a uniform organic carrier;

[0033] Weigh 75% silver powder, 5% glass powder, 10% organic carrier, Nd according to the formula ratio 2 O 3 0.02%, Eu 0.02%, the rest is solvent, mix them evenly in a planetary mixer or other mixers, and then disperse them to less than 10μm on a three-roller machine to make positive silver paste for crystalline silicon solar cells. The ...

Embodiment 3

[0036] The composition and weight percentage of the positive silver conductive paste of this embodiment: 80% silver powder, 3% glass powder, 5.5% organic carrier, Gd 2 SO 3 0.02%, Er 2 CO 3 0.02%, the rest is solvent. The particle size of the silver powder is 1.5~3.5 microns, and the tap density is 4~6g / m 3 Spherical silver powder; glass powder is PbO-TeO 2 Series of glass powder with a particle size of 0.5-3 microns.

[0037] Preparation of organic carrier: 3% acrylic resin, 8% vinyl acetate resin, 50% propylene glycol butyl ether, and 40% ethylene glycol butyl ether were dissolved at 80°C for 2 hours to obtain a uniform organic carrier;

[0038] Weigh 80% silver powder, 3% glass powder, 5.5% organic carrier, Gd according to the formula ratio 2 SO 3 0.02%, Er 2 CO 3 0.02%, the rest is solvent. Mix it evenly in a planetary mixer or other mixers, and then disperse it to less than 10μm on a three-roller to make a crystalline silicon solar cell positive silver paste. The slurry i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Average fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com