AuNCs@521-MOF (metal-organic framework) nano-sheet compound, preparation method thereof and application

A technology of nanosheets and composites, applied in nanotechnology, nanotechnology, nanotechnology for sensing, etc., can solve problems such as difficult to use on-site testing, complicated operation, expensive equipment, etc., and achieve good physical and chemical stability and Effects of electrochemical activity, good repeatability, and strong bioaffinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0073] On the one hand, the present invention also provides a preparation method of AuNCs@two-dimensional Zr-MOF nanosheet composite, including:

[0074] uniformly mixing zirconium oxychloride hydrate, trifluoroacetic acid and N,N'-diethylformamide to form a zirconium salt solution;

[0075] 4', 4"', 4"'"-nitrilotris(1,1'-biphenyl-4-carboxylic acid) and N,N'-diethylformamide were uniformly mixed to form an organic solution;

[0076] Mix the zirconium salt solution, organic solution, polyvinylpyrrolidone and ethanol, and stir at 45-60°C for 2-3 days, then separate the solids and wash them, and the two-dimensional zirconium-based metal-organic framework nanosheets are obtained;

[0077] Disperse two-dimensional zirconium-based metal-organic framework nanosheets evenly in DMF, add gold nanoclusters, and stir at 45-60°C for 2-3 days to obtain the AuNCs@two-dimensional Zr-MOF nanosheet composite;

[0078] Preferably, the mass ratio of zirconium oxychloride hydrate, trifluoroacetic...

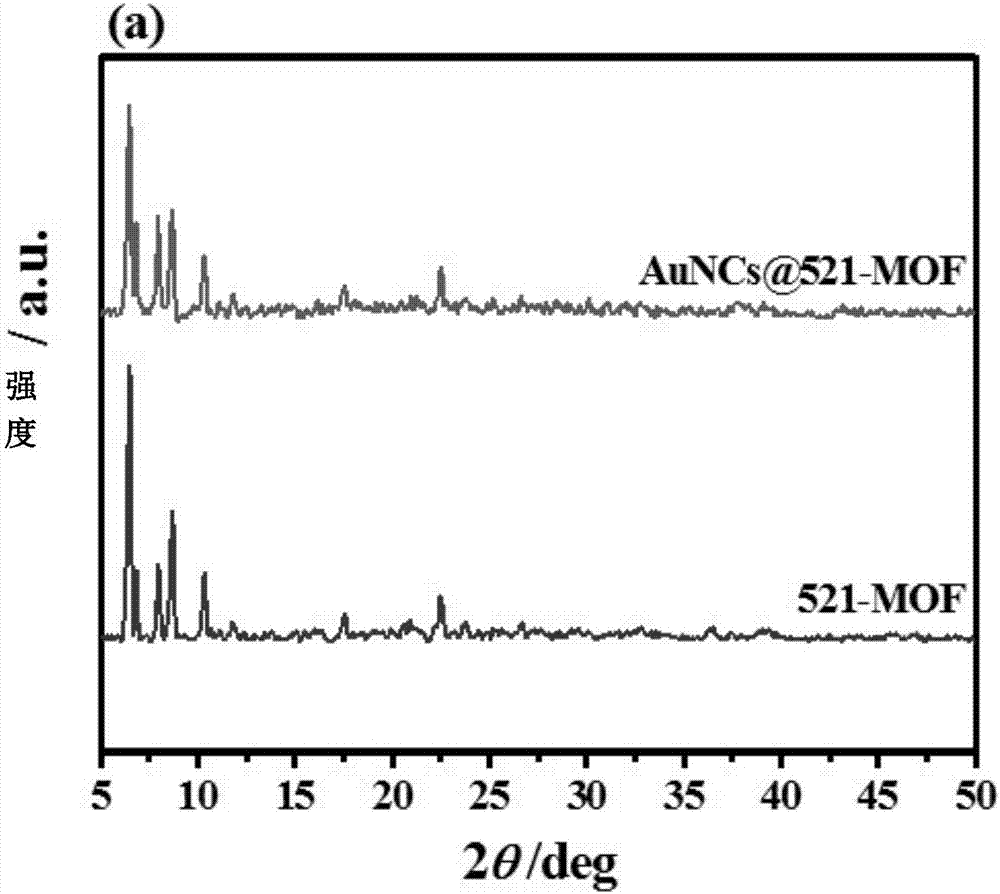

Embodiment 1

[0106] Preparation of PVP-stabilized two-dimensional 521-MOF

[0107] Zirconia dichloride hydrate (ZrOCl 2 8H 2 O) (0.10 mmol, 35.0 mg) was dissolved in N,N′-diethylformamide (DEF) (1.5 mL) and trifluoroacetic acid (TFA) (0.6 mL) in a 10.0 mL screw cap vial, and the mixture was sonicated for 10 min. Then, 40.0 mg of 4', 4"', 4"'"-nitrilotris(1,1'-biphenyl-4-carboxylic acid) (H 3 A solution of NBB) (0.05mmol) was ultrasonically dissolved in DEF (1.5mL) for 10 minutes; the zirconium salt solution was added to the organic solution to obtain a mixed solution, and then 384.0mg of polyvinylpyrrolidone (PVP) was added to the obtained mixed solution (Mw ≈ 24,000) and sonicate in 3.0 mL of ethanol for 10 min. The above mixture was sonicated for 30 minutes and then stirred at 45-60 °C for 2-3 days. The resulting yellow suspension was centrifuged at 10000 rpm for 3 minutes to pellet it. Finally, the sample was washed with DMF to remove excess precursor, and centrifuged at 10,000 rpm ...

Embodiment 2

[0115] Au electrodes (AE) with a diameter of 3 mm (available from Aida Hengsheng Technology Co., Ltd. (Tianjin, China)) were used and cleaned before use. First, AE was polished using 0.05 mm alumina slurry and a P1 gold polisher, rinsed with ultrapure water (≥18.2Ω.cm) five times, and then washed with piranha solution (H 2 SO 4 :H 2 o 2 volume ratio = 7:3; warning: piranha wash reacts violently with organic solvents) wash AE for 15 min, then wash thoroughly with ultrapure water and dry under nitrogen; finally, in 0.5M H 2 SO 4 AEs were electrochemically washed in solution and under potential cycling conditions between −0.2 and 1.6 V until reproducible cyclic voltammograms were observed, then the activated electrodes were rinsed with ultrapure water and dried under nitrogen .

[0116] Add 5.0 μL of AuNCs@521-MOF nanosheets (prepared in Example 1) aqueous suspension (0.1 mg·mL) dropwise on the activated AE surface -1 ), and then with ultrapure N 2 It was dried; then, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com