Concrete hardening waterproof agent and preparation method and application method thereof

A technology of concrete and waterproofing agent, applied in the direction of coating, wax coating, etc., can solve the problems of not being able to compensate for concrete shrinkage cracks, unfavorable strength of concrete in the later stage, and influence of waterproof and impermeable performance, etc., to achieve simple use method, improve strength and waterproof performance , the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

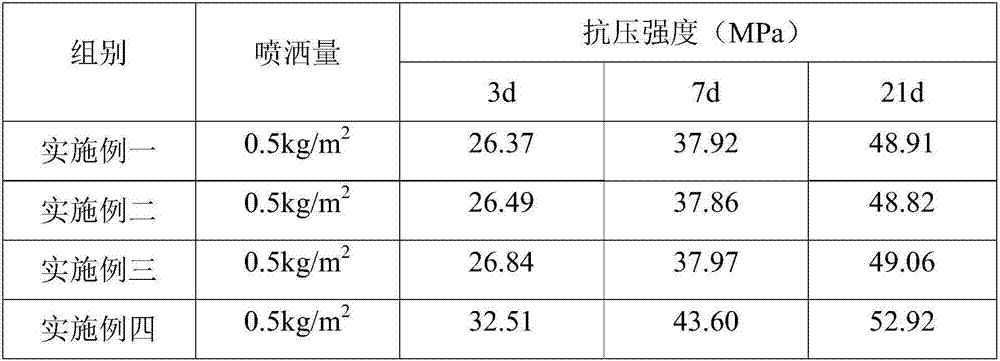

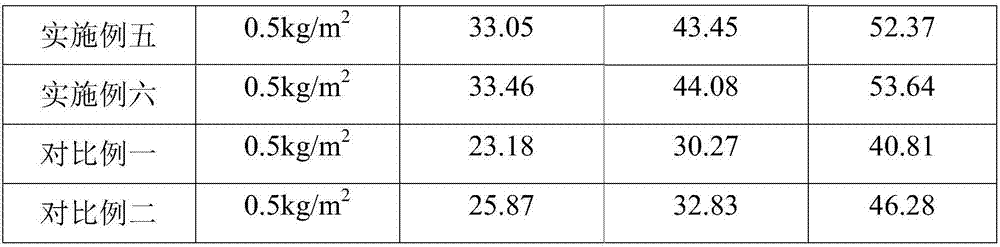

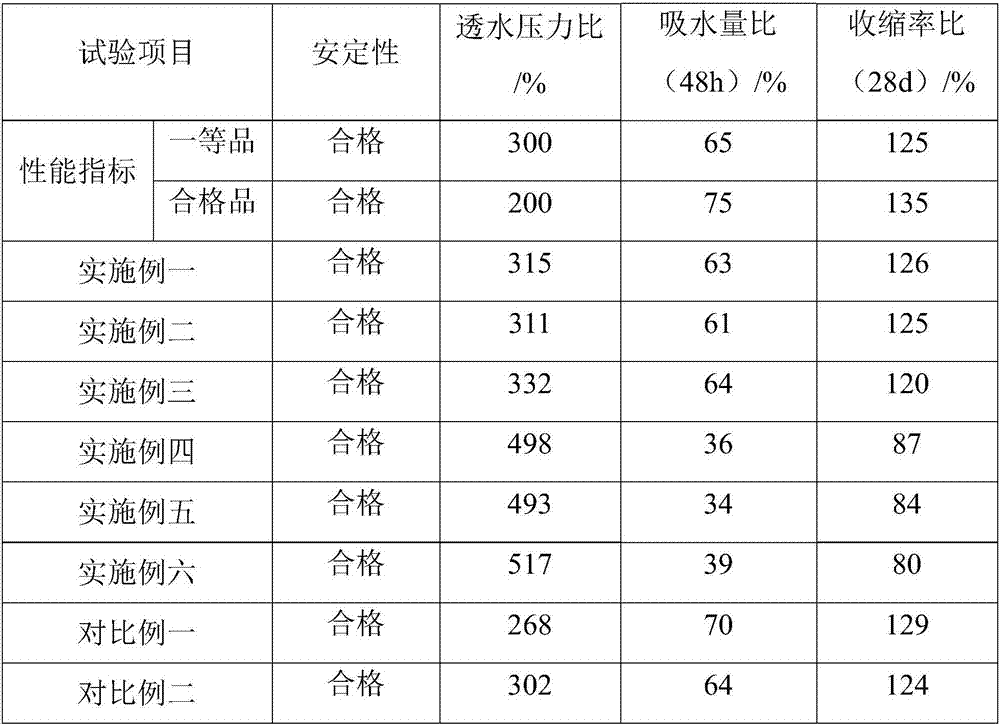

Examples

preparation example Construction

[0020] Preferably, the raw material components of the concrete hardening and waterproofing agent also include: 15-20 parts by weight of triisopropanolamine, 6-8 parts by weight of sodium metabisulfite, 0.5-1 part by weight of potassium chloride, hydrophilic fumed silica 4-6 parts by weight, 9-11 parts by weight of calcium lignosulfonate and 10-12 parts by weight of acrylated epoxy resin; wherein, the preparation method of acrylated epoxy resin comprises the following steps: epoxy resin E44, Mix the polymerization inhibitor hydroquinone and the catalyst benzylamine evenly, raise the temperature to 100-108°C, then add acrylic acid dropwise, keep it warm for 60-80 minutes, raise the temperature to 148-152°C, keep it warm until the acid value test result is less than 0.4mg / g , to obtain acrylated epoxy resin; the mass ratio of epoxy resin, acrylic acid, polymerization inhibitor and catalyst is (840~860):(80~90):(4~6):1.

[0021] In addition, the present invention also provides a p...

Embodiment 1

[0026] This embodiment provides a concrete hardening and waterproofing agent, the raw material components are by weight, including:

[0027] 90 parts by weight of No. 52 chlorinated paraffin, 5 parts by weight of ammoniacal liquor with a mass fraction of 25%, 8 parts by weight of stearic acid, 11 parts by weight of magnesium fluorosilicate, 1 part by weight of defoamer (n-amyl alcohol), preservative ( sodium benzoate) 0.6 parts by weight and 180 parts by weight of water.

[0028] According to above-mentioned raw material, adopt the preparation method of concrete hardening waterproofing agent provided by the invention, prepare concrete hardening waterproofing agent:

[0029] S1: Mix all raw material components evenly, adjust the pH value to 5.5, and then heat at 80°C for 15 minutes;

[0030] S2: adjust the pH value of the product obtained in S1 to 7.5, then heat at 95° C. for 10 minutes, and then cool to room temperature to obtain a concrete hardening and waterproofing agent. ...

Embodiment 2

[0032] This embodiment provides a concrete hardening and waterproofing agent, the raw material components are by weight, including:

[0033] 110 parts by weight of No. 52 chlorinated paraffin, 4 parts by weight of ammoniacal liquor with a mass fraction of 25%, 9 parts by weight of stearic acid, 9 parts by weight of magnesium fluorosilicate, 3 parts by weight of defoamer (n-amyl alcohol), preservative ( sodium benzoate) 0.4 parts by weight and 220 parts by weight of water.

[0034] According to above-mentioned raw material, adopt the preparation method of concrete hardening waterproofing agent provided by the invention, prepare concrete hardening waterproofing agent:

[0035] S1: Mix all raw material components evenly, adjust the pH value to 6.0, and then heat at 90°C for 20 minutes;

[0036] S2: adjust the pH value of the product obtained in S1 to 8.0, then heat at 105° C. for 15 minutes, and then cool to room temperature to obtain a concrete hardening and waterproofing agent. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com