Hydrogenation catalyst suitable for production of aviation kerosene, preparation method and application thereof

A technology for hydrogenation catalysts and aviation kerosene, which is applied in the direction of catalyst activation/preparation, molecular sieve catalysts, chemical instruments and methods, etc. It can solve the problems of lack of large-scale industrial production, high cost of graphene preparation, and inability to crack cracking performance. , to achieve obvious thermal conductivity advantages, reduce the roasting stage, and achieve the effect of excellent thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] 1, the preparation method of graphite oxide, concrete steps are as follows:

[0045] 101) Weighing 1g of natural graphite, 1g of anhydrous sodium nitrate and 50ml of concentrated sulfuric acid with a mass fraction ≥ 75%;

[0046] 102) Slowly put natural graphite and anhydrous sodium nitrate into concentrated sulfuric acid placed in an ice bath, slowly add 6 g of potassium permanganate for oxidation treatment, and stir for 0.5-2 hours to obtain a mixed solution;

[0047] 103) Place the mixed solution in a water bath at a temperature of 35° C., stir for 2 hours, and slowly add 200 ml of deionized water to the mixed solution during the stirring process;

[0048] 104) Then place the mixed solution in an oil bath with a temperature of 98° C., continue to stir and react for 0.5 h, then dilute the mixed solution with deionized water to 400 ml to obtain a diluted solution;

[0049] 105) Slowly add 30ml of hydrogen peroxide with a mass fraction of 30% to the diluted solution, a...

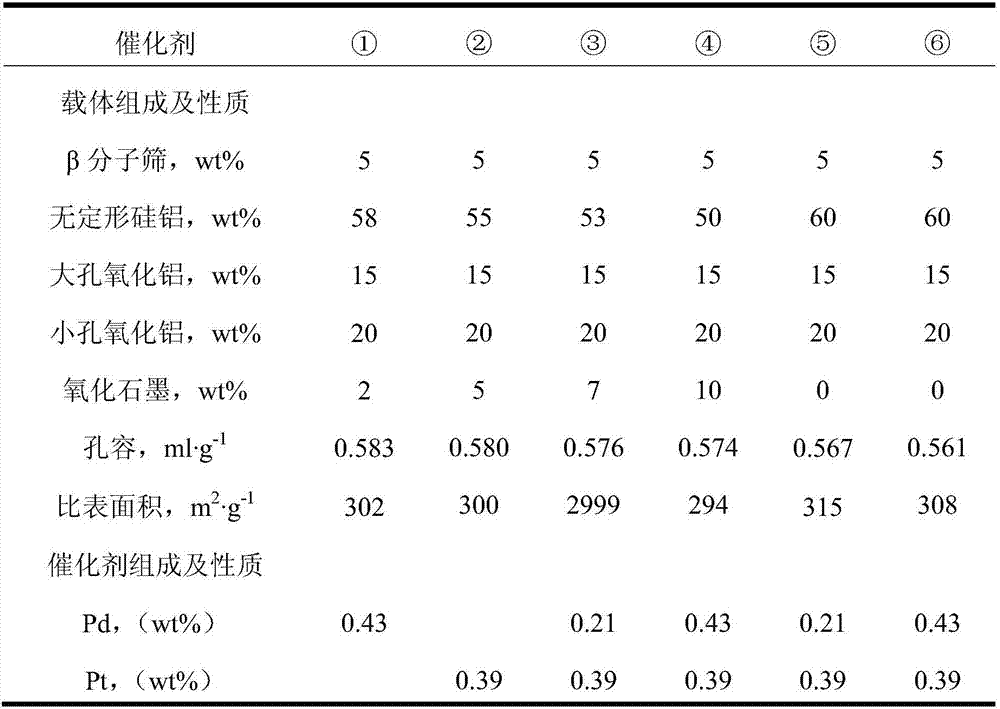

Embodiment 1

[0058] Catalyst 1. preparation method, concrete steps are as follows:

[0059] 1) Take by weighing 0.5g of β molecular sieve, 5.8g of amorphous silica-alumina, 1.5g of macroporous alumina, 0.2g of graphite oxide and 0.1g of turmeric powder;

[0060] 2) macroporous alumina, β molecular sieve, amorphous silica-alumina, modified graphene and squash powder are uniformly mixed to obtain a mixture;

[0061] 3) Weighing 2g of small-pore alumina and 6g of nitric acid solution with a mass fraction of 4% and mixing them uniformly as a binder;

[0062] 4) The resulting mixture is impregnated with 20 mL of 0.02 mol / L PdCl 2 solution to obtain a mixed solution;

[0063] 5) Heat the obtained mixed solution in a water bath at a temperature of 75° C., and add 5 ml of 0.2 mol / L NaBH to the mixed solution under nitrogen protection 4 Carry out the reduction treatment for 4 hours until no more gas is released in the system to obtain a reaction slurry;

[0064] 6) After the reaction slurry is ...

Embodiment 2

[0068] Catalyst ② preparation method, concrete steps are as follows:

[0069] 1) Take by weighing 0.5g of β molecular sieve, 5.5g of amorphous silica-alumina, 1.5g of macroporous alumina, 0.5g of graphite oxide and 0.1g of turmeric powder;

[0070] 2) macroporous alumina, β molecular sieve, amorphous silica-alumina, modified graphene and squash powder are uniformly mixed to obtain a mixture;

[0071] 3) Weighing 2g of small-pore alumina and 6g of nitric acid solution with a mass fraction of 4% and mixing them uniformly as a binder;

[0072] 4) The resulting mixture was impregnated with 20 mL of 0.01 mol / L PtCl 4 solution to obtain a mixed solution;

[0073] 5) Heat the obtained mixed solution in a water bath at a temperature of 75° C., and add 5 ml of 0.2 mol / L NaBH to the mixed solution under nitrogen protection 4 Carry out the reduction treatment for 4 hours until no more gas is released in the system to obtain a reaction slurry;

[0074] 6) After the reaction slurry is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com