Method for preparing 1, 2-pentanediol from n-butanol as raw material

A process method and n-butanol technology, applied in the field of preparing 1,2-pentanediol, can solve the problems of flammable and explosive raw materials, corrosion of formaldehyde environment, pollution, etc., and achieve simple post-processing, simple operation and short time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

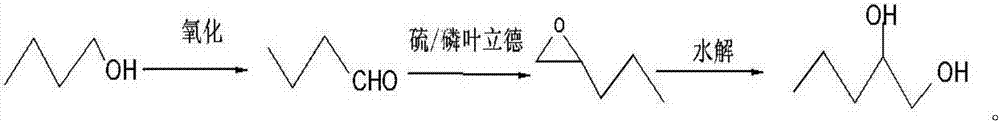

[0019] The synthetic technique of the present invention is as follows:

[0020]

[0021] In the first step, n-butanol is oxidized to prepare n-butyraldehyde

[0022] Its specific synthesis method is: n-butanol is oxidized to prepare n-butyraldehyde: add 0.1mol n-butanol (7.4g), 1mmol TEMPO (0.16g), 34ml dichloromethane, 0.01mol KBr (1.19g) into a 250ml three-necked flask respectively Add it into a three-necked flask after adding 5ml of water, then place it in an ice-water bath at -8°C, and add 0.11mol of sodium hypochlorite aqueous solution (the pH of the sodium hypochlorite solution is 9.5) dropwise with a constant pressure dropping funnel. ℃-30℃, reaction time 5-60min, wash with water, stand to separate the liquid, and remove the solvent under reduced pressure to obtain n-butyraldehyde.

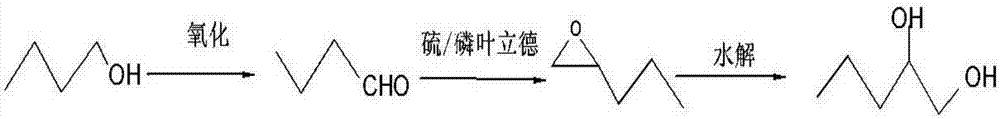

[0023] Using the same conditions as the above-mentioned oxidation method, the difference is that different oxidants are used, and the yield of the product is shown in Table 1.

[0024]...

Embodiment 2

[0027] The second step, the preparation of 1,2-epoxypentane

[0028] Add 0.25 mol of n-butyraldehyde, 0.38 mol of methyl sulfide ylide, potassium carbonate (0.75 mol), and then add 3 mL of dry isopropanol, 0.3 mL of ethanol, and react at room temperature for 12 hours, then add 3 mL of water into a nitrogen-protected reaction flask. Quench the reaction, let stand for liquid separation, dry over anhydrous sodium sulfate, and filter to obtain 1,2-epoxypentane.

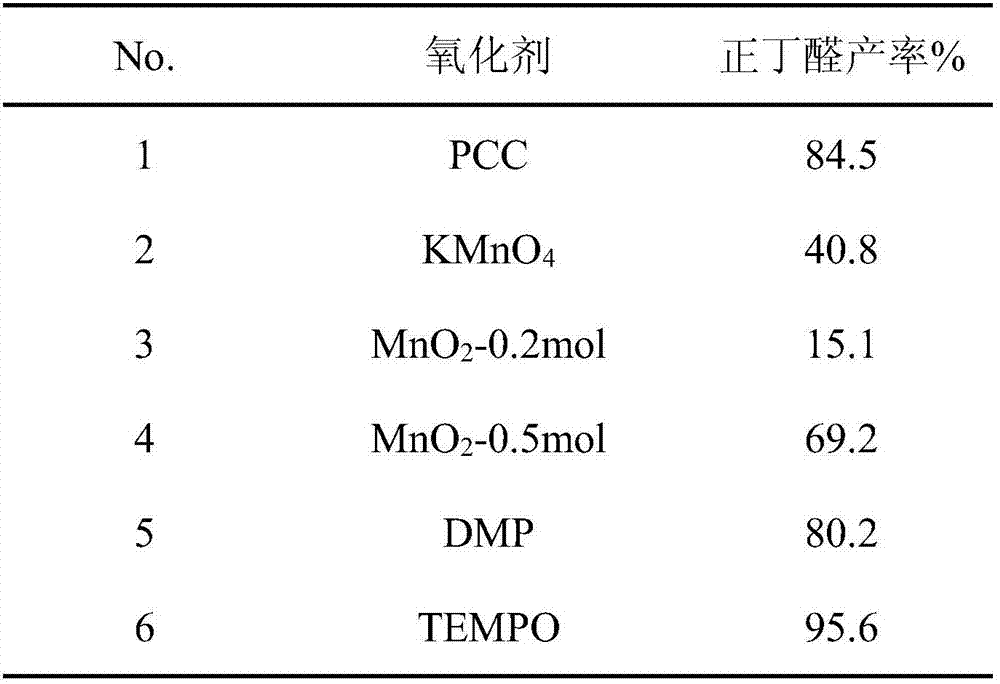

[0029] Using the same conditions as the above-mentioned ylide reaction, the difference is that different ylide reagents are used, and the yield of the product is shown in Table 2.

[0030] Table 2

[0031]

Embodiment 3

[0033] The third step, the preparation of 1,2-pentanediol

[0034] Add 5g of potassium hydroxide into 50g of 85% methanol aqueous solution, stir evenly, and heat to reflux, add the separated 1,2-epoxypentane dropwise to the methanol aqueous solution containing a small amount of potassium hydroxide to open the ring, and keep the aqueous solution The pH value is 8, and the 1,2-pentanediol is obtained by static separation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com