A kind of allyl alcohol polyoxypropylene polyoxyethylene random polyether and preparation method thereof

A technology of allyl alcohol polyoxypropylene polyoxyethylene and atactic polyether, which is applied in the field of organic polymer compound preparation, can solve the problems of uneven foam opening, difficult molecular weight, and high content, and achieve chain growth speed, Increase the effect of mass transfer and ensure the effect of mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

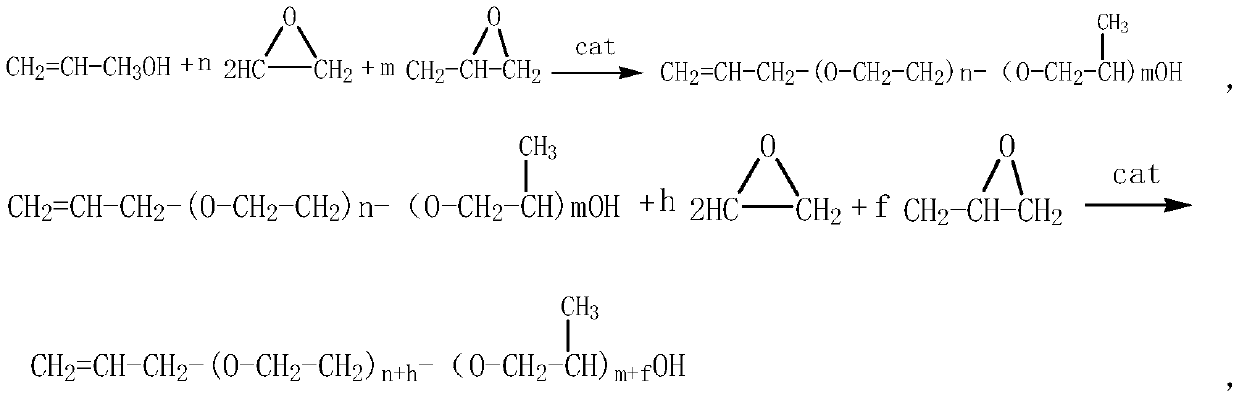

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: Preparation of allyl alcohol random polyether oligomer

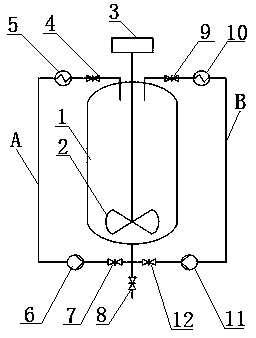

[0036] Add 400g of allyl alcohol and 0.6g of boron trifluoride ether into a 2.5L high-pressure stirred reactor, and vacuumize with a vacuum pump, using N 2 Replace the air in the reactor. After three replacements, turn off the vacuum and start to heat up the material to 30°C under a vacuum degree ≥ -0.096MPa. After that, continue to add 980g of a mixture of ethylene oxide and propylene oxide, ethylene oxide and The weight ratio of propylene oxide is 1:1. Control the reaction temperature at 20-40°C, and the pressure in the reactor at -0.05-0.2Mpa. After the addition, keep warm and continue the reaction until the pressure no longer drops. The entire reaction addition time is about 6h. After the reaction is completed, vacuum degassing, keep the vacuum ≥ -0.098MPa for 10 minutes, and then discharge to obtain the finished product for later use. The product is analyzed by a nuclear magnetic resonance ana...

Embodiment 2

[0043] Embodiment 2: experiment with theoretical molecular weight 2000 feed intake

[0044] Add 150g of allyl alcohol polyether oligomer and 3.0g of sodium methoxide into a 2.5L stirring and 2-way external circulation reactor, and use N 2 After replacing the air in the reaction kettle three times, under the vacuum degree ≥ -0.096MPa, start to vacuumize and raise the temperature to 90°C to remove the methanol generated by the reaction, and keep it for 1 hour. After dealcoholization is completed, the temperature is lowered to 65°C, and 1350 g of a mixture of ethylene oxide and propylene oxide is continuously added, and the weight ratio of ethylene oxide to propylene oxide is 1:1. Control the reaction temperature at 60-70°C, and the pressure in the reactor at -0.02-0.4Mpa. After the addition is complete, keep warm and continue the reaction until the pressure no longer drops. The entire reaction addition time is about 8 hours. After the reaction is completed, use vacuum degassing...

Embodiment 3

[0053] Embodiment 3: experiment with theoretical molecular weight 4000 feed intake

[0054] Add 100 g of allyl alcohol polyether oligomer obtained in Example 1, 2.5 g of sodium methylate in a 2.5 L stirring and stirring and adding 2 external circulation reactors, and use N 2 After replacing the air in the reaction kettle three times, under the vacuum degree ≥ -0.096MPa, start to vacuumize and raise the temperature to 90°C to remove the methanol generated by the reaction, and keep it for 1 hour. After dealcoholization is completed, the temperature is lowered to 65°C, and 1900 g of a mixture of ethylene oxide and propylene oxide is continuously added, and the weight ratio of ethylene oxide to propylene oxide is 3:1. Control the reaction temperature at 65-75°C, and the pressure in the reactor at -0.02-0.4Mpa. After the addition, keep warm and continue the reaction until the pressure no longer drops. The entire reaction addition time is about 10h. After the reaction is completed,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com