Improved ammonia-method desulfurization process and system

The technology of ammonia desulfurization and processing system is applied in the field of improved ammonia desulfurization process and system, which can solve the problems of high impurity content, complex composition, tailing, etc., so as to alleviate the high cost, widen the application field and obtain considerable economic benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further explained by specific examples below.

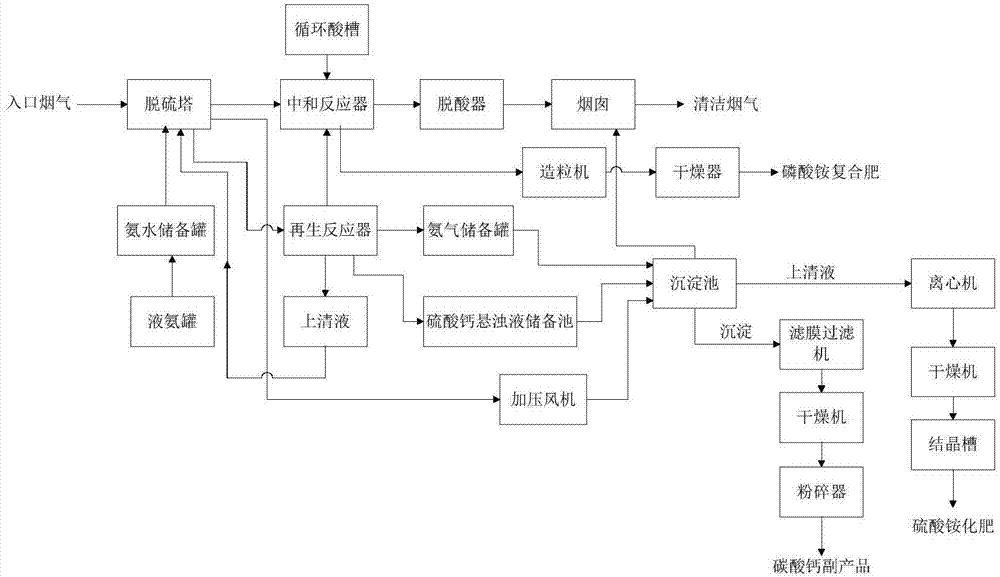

[0039] like figure 1 As shown, an improved ammonia desulfurization system, the system includes desulfurization tower, ammonia addition system, regeneration tank, pressurized fan, calcium sulfate suspension storage tank, sedimentation tank, neutralization reactor, circulating acid tank, fertilizer processing system, a calcium carbonate processing system and a chimney; the desulfurization tower is connected to the ammonia addition system through pipelines; the liquid ammonia tank of the ammonia addition system is connected to the ammonia storage tank through pipelines; the fertilizer processing system includes a centrifuge, Drier, granulator and crystallization tank; Described calcium carbonate processing system comprises membrane filter, drier and pulverizer; The flue gas that described pressurization blower comes out desulfurization tower is passed into sedimentation pond; Described regenerati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com