Integrated ozone coupled ceramic membrane type MBR (membrane bioreactor) and treatment process

A technology of membrane bioreactor and treatment process, applied in biological water/sewage treatment, anaerobic digestion treatment, oxidized water/sewage treatment, etc. Can not meet the discharge standards and other problems, to achieve the effect of strengthening the denitrification function, avoiding sludge loss, and improving biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

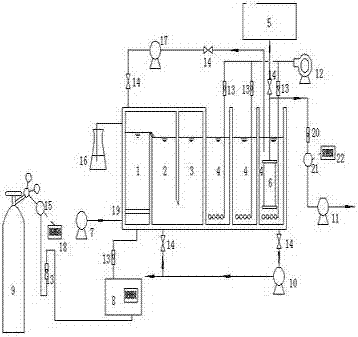

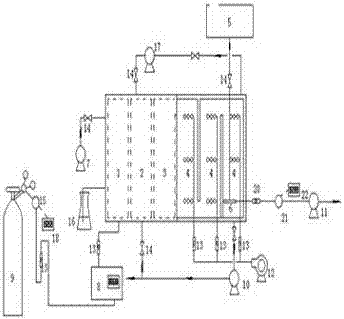

[0022] Such as figure 1 , At this time, except for the stop valve (14) between the ceramic membrane module (6) and the backwash tank (5), the stop valve (14) is closed, the rest of the stop valves (14) are in open mode, and the water inlet pump (7) The sewage is input to the bottom of the ozonation reaction zone (1) for ozone reaction. After the reaction, the sewage flows from the top of the ozonation reaction zone to the anoxic reaction zone (2), and then flows from the bottom of the anoxic reaction zone (2) to the anaerobic reaction zone ( 3), such as figure 2 The top view of the reactor, the sewage after treatment in the anaerobic reaction zone (3) flows through the three-part aerobic ceramic membrane MBR (4) separated by plexiglass plates, and uses the life activities of microorganisms to degrade the pollution of organic matter, nitrogen and phosphorus. The ceramic membrane module (6) is located at the end of the aerobic zone. After the sewage is filtered by the ceramic me...

Embodiment 2

[0024] At this time, except for the stop valve (14) between the ceramic membrane module (6) and the backwash water tank (5), the stop valve (14) is open, and the other water stop valves (14) are in closed mode, and the backwash water tank (5) is in the closed mode. The backwash water is used for backwashing of the ceramic membrane module (6), when the suction flow meter (20) on the ceramic membrane water production pipe section detects that the flow rate of the water is lower than 20L / m 2 When h, start the backwash system, only open the stop valve between the backwash water tank (5) and the ceramic membrane module (6), but the aeration device is still open, and the rest of the water inlet section, return section and sludge return section The stop valve (14) is closed, and the ozone generator (8) is also closed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com