Preparation method of bioactive glass composite material

A technology of bioactive glass and composite materials, applied in the field of preparation of bioactive glass composite materials, can solve the problems of low mechanical strength, poor resistance to enzymatic hydrolysis, low mineralization activity, etc., to maintain mechanical properties, improve degradation ability, The effect of fast mineralization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

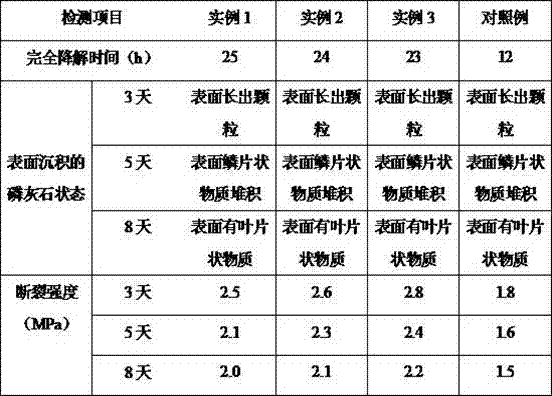

Examples

example 1

[0022] In parts by weight, respectively select 70 parts of absolute ethanol, 5 parts of deionized water, and 2 parts of ammonia water into a beaker, stir and mix for 20 minutes to obtain a mixed solution, add 3% calcium nitrate of the mixed solution to the beaker, stir for 20 minutes and use The mass fraction is 15% ammonia water to adjust the pH to 9.5, and after adjustment, the material is discharged to obtain the adjustment solution; according to the mass ratio of 3:1, the adjustment solution and ethyl orthosilicate are mixed, stirred until a white precipitate appears, and the precipitate is collected after centrifugation. The precipitate was washed twice with acetone, then put into an oven, dried at 60°C for 6 hours, put into a tube furnace after drying, raised to 500°C at a heating rate of 10°C / min, kept for 40 minutes, and then cooled to room temperature. and discharging to obtain bioactive glass; by parts by weight, respectively select 10 parts of wormwood, 5 parts of ca...

example 2

[0024] In parts by weight, respectively select 75 parts of absolute ethanol, 8 parts of deionized water, and 3 parts of ammonia water into a beaker, stir and mix for 25 minutes to obtain a mixed solution, add mixed solution quality 4% calcium nitrate in the beaker, stir for 25 minutes and use The mass fraction is 15% ammonia water to adjust the pH to 9.8, and discharge the material after adjustment to obtain the adjustment solution; according to the mass ratio of 3:1, mix the adjustment solution and ethyl orthosilicate, stir until white precipitate appears, collect the precipitate after centrifugation, and The precipitate was washed 3 times with acetone, then put into an oven, dried at 70°C for 8 hours, put into a tube furnace after drying, raised to 525°C at a heating rate of 13°C / min, kept for 45 minutes, and then cooled to room temperature. and discharging to obtain bioactive glass; by weight parts, respectively select 13 parts of wormwood, 7 parts of cattail grass, 10 parts...

example 3

[0026]In parts by weight, respectively select 80 parts of absolute ethanol, 10 parts of deionized water, and 4 parts of ammonia water into a beaker, stir and mix for 30 minutes to obtain a mixed solution, add 5% calcium nitrate of the mixed solution in the beaker, stir for 30 minutes and use The mass fraction is 15% ammonia water to adjust the pH to 10.0, and discharge the material after adjustment to obtain the adjustment liquid; according to the mass ratio of 3:1, mix the adjustment liquid and tetraethyl orthosilicate, stir until a white precipitate appears, collect the precipitate after centrifugation, and The precipitate was washed 4 times with acetone, then put into an oven, dried at 80°C for 10 hours, put into a tube furnace after drying, raised to 550°C at a heating rate of 15°C / min, kept for 50 minutes, and then cooled to room temperature. and discharging to obtain bioactive glass; by parts by weight, respectively select 15 parts of wormwood, 10 parts of cattail grass, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com