Waterproof metal paint for shell of filter and preparation method of waterproof metal paint

A water resistance and filter technology, applied in the field of painting, can solve the problems of rough surface, local accumulation, large surface tension, etc., and achieve the effect of natural and soft luster, good air permeability, and small surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

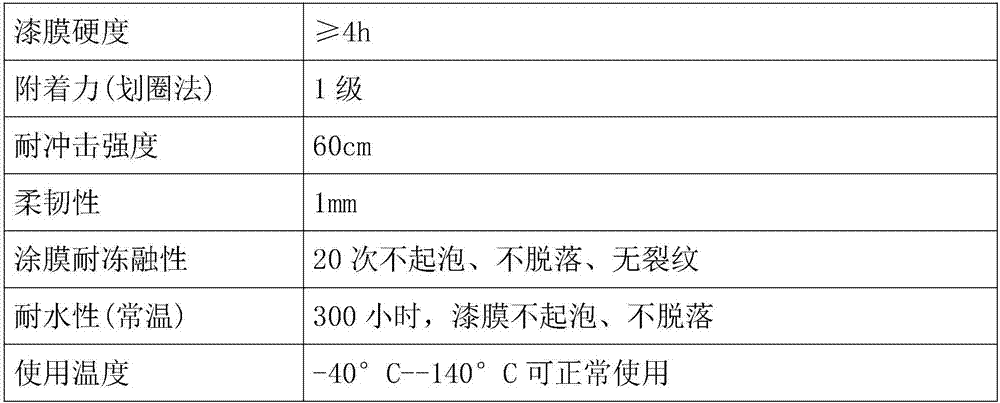

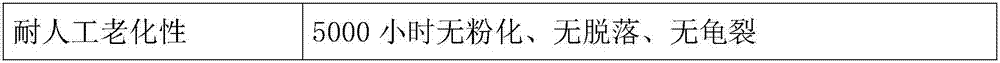

Image

Examples

Embodiment 1

[0046] Example 1: A metal paint used for the filter housing, which mainly includes the following components: 31 parts of deionized water, 3 parts of talcum powder, 1 part of titanium white powder, 1 part of barium sulfate, and organic silicon defoamer 1 part, 1 part of leveling agent, 1 part of nano-titanium dioxide, 16 parts of sericite powder, 5 parts of nano-calcium carbonate powder, 5 parts of potassium methyl silicate, 1 part of fumed silica, 5 parts of pearl powder, 13 parts of emulsion , 3 parts of associative alkali swelling thickener, 6 parts of organic amine salt dispersant, 16 parts of polyether polyol wetting agent, 9 parts of silicon carbide, 12 parts of alumina, 10 parts of graphite, 8 parts of tungsten carbide, 3 parts of boron nitride.

[0047] A preparation method for metal paint used in a filter housing, specifically comprising the steps of:

[0048]1) Add the formula amount of water, antifreeze, film-forming aid, barium sulfate, silicone defoamer and leveli...

Embodiment 2

[0067] Example 2: A metal paint used for the filter housing, which mainly includes the following components: 36 parts of deionized water, 5 parts of talcum powder, 3 parts of titanium white powder, 3 parts of barium sulfate, and organic silicon defoamer 3 parts, 3 parts of leveling agent, 3 parts of nano-titanium dioxide, 21 parts of sericite powder, 8 parts of nano-calcium carbonate powder, 8 parts of potassium methyl silicate, 3 parts of fumed silica, 10 parts of pearl powder, 16 parts of emulsion , 5 parts of associative alkali swelling thickener, 10 parts of organic amine salt dispersant, 18 parts of polyether polyol wetting agent, 13 parts of silicon carbide, 15 parts of alumina, 15 parts of graphite, 10 parts of tungsten carbide, 5 parts of boron nitride.

[0068] A preparation method for metal paint used in a filter housing, specifically comprising the steps of:

[0069] 1) Add the formula amount of water, antifreeze, film-forming aid, barium sulfate, silicone defoamer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com