Preparation method of NiCu film supported nano-Pt composite catalyst for electrooxidation of ethanol

A composite catalyst and electro-oxidation technology, which is applied in circuits, electrical components, battery electrodes, etc., can solve problems such as complex operation process, influence on catalytic activity of catalyst, specific surface area of composite catalyst, and differences in surface chemical properties, so as to achieve simple operation and reduce Precious metal poisoning, the effect of reducing the content of precious metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of a kind of NiCu film-loaded nano-Pt electrooxidation ethanol composite catalyst of the present invention comprises the following steps:

[0024] 1) Dissolve copper salt and nickel salt in water at a molar ratio of 0.01 to 11:1, preferably a molar ratio of copper salt to nickel salt of 0.2 to 1:1, and prepare NiCu bimetallic film by constant potential electrochemical co-deposition method wherein the copper salt is one of copper chloride, copper sulfate, copper nitrate or copper acetate; the nickel salt is one of nickel chloride, nickel sulfate, nickel nitrate and nickel acetate; wherein the constant potential chemical co-deposition method The electrolyte is a mixed aqueous solution of copper salt and nickel salt, the cathode is conductive glass or titanium sheet, the anode is platinum electrode, the deposition potential is -0.5~-1.3V, the preferred deposition potential is -0.6~-0.9V, and the electrodeposition time is 300-1200s, preferably 300-600...

Embodiment 1

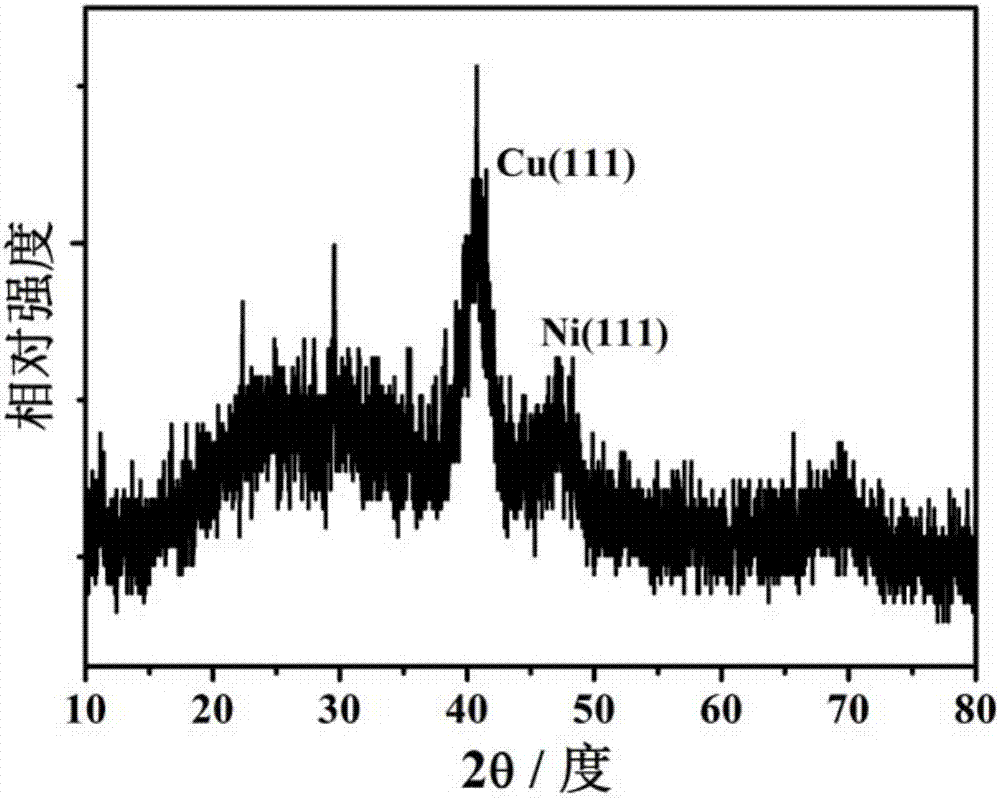

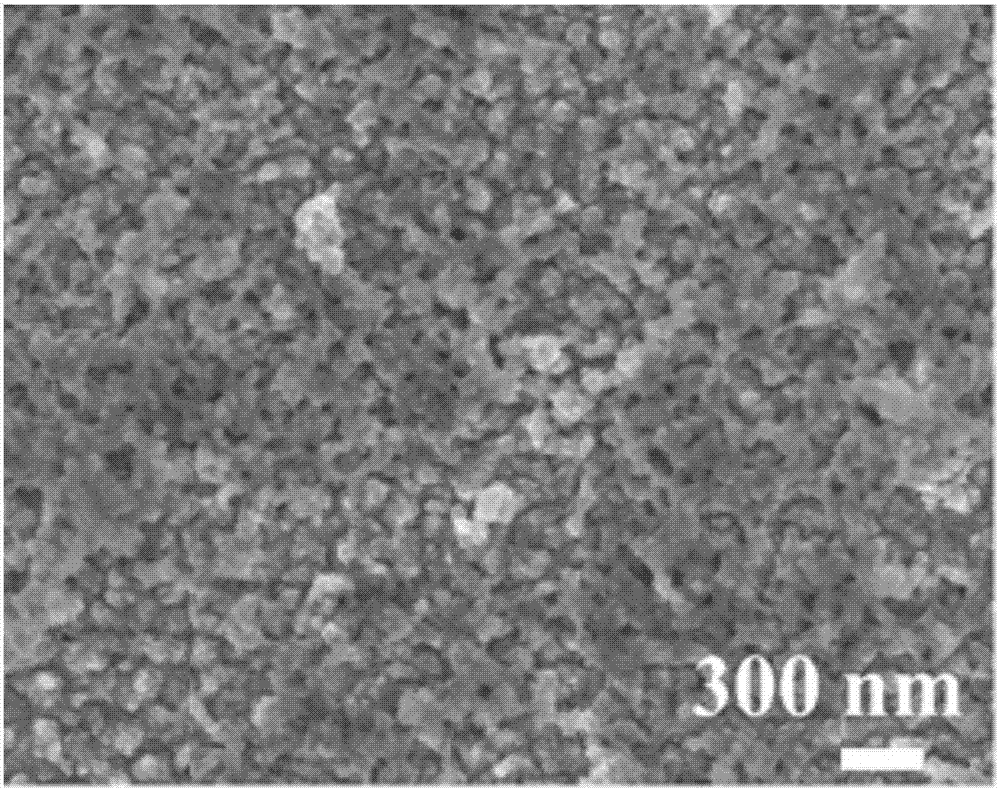

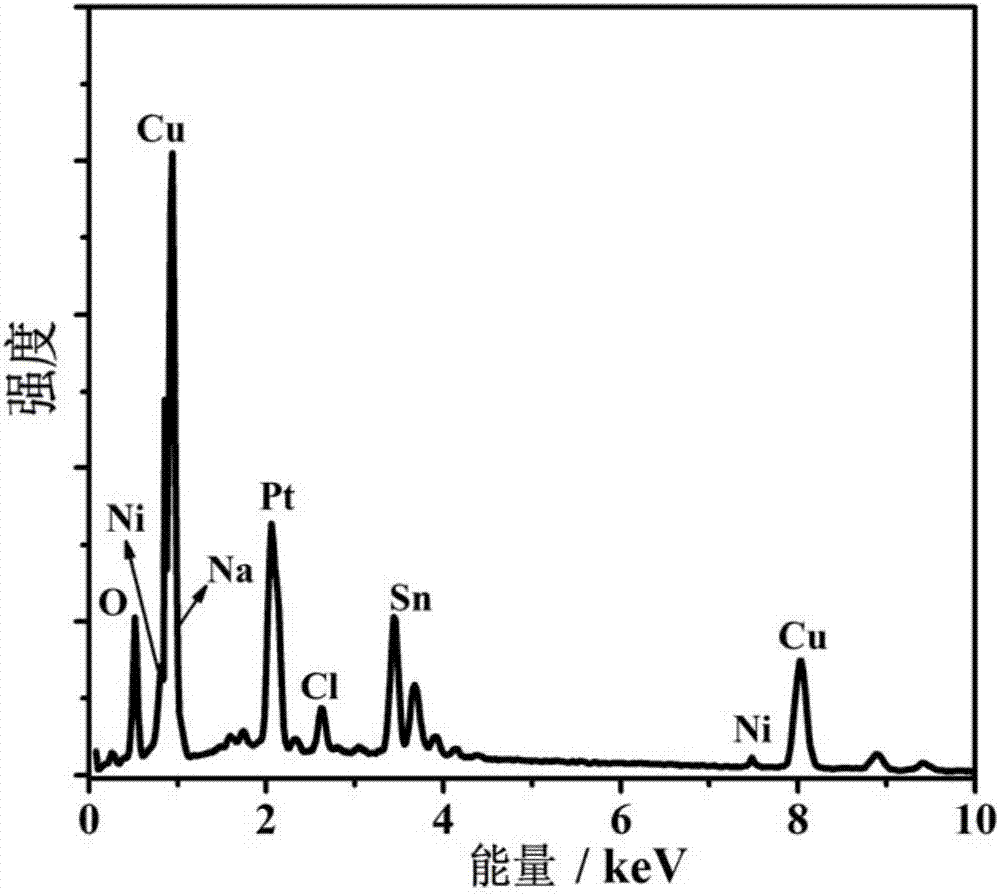

[0031] 1) Prepare 0.02mol / L CuSO 4 and 0.04mol / L NiSO 4 The mixed aqueous solution was stirred and dispersed evenly at 70°C as the electrolyte; at the deposition potential of -0.6V, the electrodeposition time was 600s, and the NiCu bimetallic film was co-deposited on the conductive glass;

[0032]2) Add dropwise 0.05mL of 10g / L chloroplatinic acid solution on the NiCu bimetallic film, then immediately dropwise add 0.05mL of 0.02mol / L sodium borohydride and 0.05mol / L sodium hydroxide mixed alkaline solution to obtain NiCu film supported nano-Pt electrooxidation ethanol composite catalyst, the molar ratio of copper ions and nickel ions is 0.5:1.

[0033] The NiCu thin film loaded nano-Pt electro-oxidation ethanol composite catalyst prepared in the above-mentioned embodiment 1 was put into 1mol / L NaOH+1mol / L C as a working electrode after being dried in room temperature 5 h 6 In the mixed solution of OH, the performance of electrocatalytic oxidation of ethanol can be obtained ...

Embodiment 2

[0035] With reference to the method of Example 1, the difference is that the CuSO concentration of 0.01mol / L is adopted 4 and 0.05mol / L NiSO 4 The aqueous solution was mixed to finally prepare a NiCu film-supported nano-Pt electro-oxidation composite catalyst for ethanol, and the molar ratio of copper ions to nickel ions was 0.2:1.

[0036] The NiCu thin film loaded nano-Pt electro-oxidation ethanol composite catalyst prepared in the above-mentioned embodiment 2 was put into 1mol / L NaOH+1mol / L C as a working electrode after being dried in room temperature 5 h 6 In the mixed solution of OH, the performance of electrocatalytic oxidation of ethanol can be obtained by testing the cyclic voltammetry curve and current time curve. The measured peak potential is 0.638V, and the peak current is 167.0mA / mg Pt .

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com