Phosphonate radical containing phosphazene compound, molding compound and composite metallic substrate

A phosphazene compound and phosphonate-based technology, applied in the field of flame retardant materials, can solve the problems of unfavorable popularization and unsuitability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

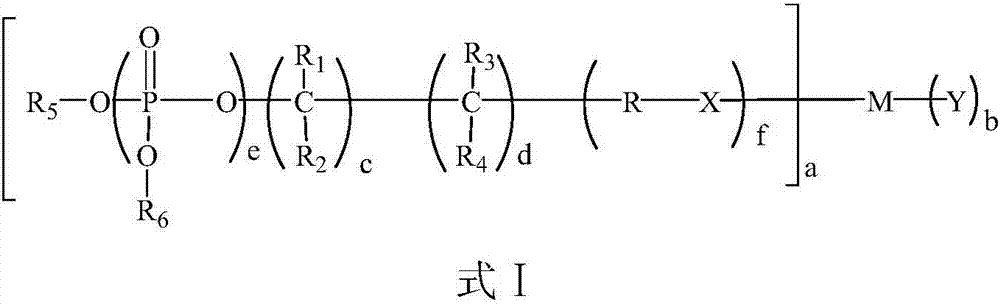

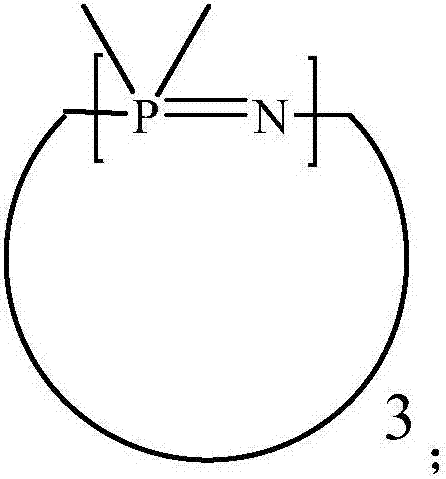

[0082] The structural formula of the phosphazene compound of the present embodiment is as follows:

[0083]

[0084] Put 1 mol of hexachlorocyclotriphosphazene, 200 ml of acetone, 1 mol of dimethyl phosphate, and 5 mol of sodium methoxide into a three-port 2000 ml glass reactor with a stirring device. % sodium hydroxide solution 620g, keep 60 ℃ of temperature, stir and react for 15 hours. After the reaction, the inorganic components and water in the system were removed by physical methods, and the solvent in the system was distilled off to obtain 1 mol of esterified product A with the ester equivalent of the above structure of 220 g / eq.

[0085] The obtained compound A is characterized by proton nuclear magnetic resonance spectrum, and the results are as follows:

[0086] 1 H NMR (CDCl 3 ,500MHz):3.42(s,15H,OC H 3 ).

[0087] The position of the characteristic peak of the infrared spectrum: the characteristic absorption peak of the P=N bond in the phosphazene skeleton...

Embodiment 2

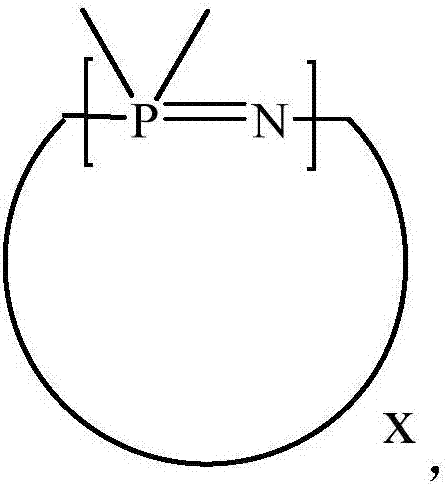

[0090] The structural formula of the phosphazene compound of the present embodiment is as follows:

[0091]

[0092] Put 1 mol of hexachlorocyclotriphosphazene, 200 ml of acetone, 1 mol of sodium acrylate, and 5 mol of sodium methoxide into a three-port 2000 ml glass reactor with a stirring device, while stirring, while blowing nitrogen, once the temperature is raised to 60 ° C, 20 % sodium hydroxide solution 620g, keep the temperature at 60°C, stir and react for 15 hours, then add 1 mol of dimethyl phosphate, continue to react for 5 hours, after the reaction, remove the inorganic components and water in the system by physical methods, distill off the system solvent to obtain 1 mol of esterified product B with the ester equivalent of the above structure being 170 g / eq.

[0093] The obtained compound B is characterized by proton nuclear magnetic resonance spectrum, and the results are as follows:

[0094] 1 H NMR (CDCl 3 ,500MHz):δ4.1(m,2H,-POC H 2 CH 2 CH 2 OP-),3.56...

Embodiment 3

[0098] The structural formula of the phosphazene compound of the present embodiment is as follows:

[0099]

[0100] Put 1 mol of hexachlorocyclotriphosphazene, 200 ml of acetone, 1 mol of glycolaldehyde, and 5 mol of sodium methoxide into a three-port 2000 ml glass reactor with a stirring device, while stirring, while blowing nitrogen, the temperature is raised to 60 ° C, and 20% of Sodium hydroxide solution 621g, keep the temperature at 60°C, stir and react for 15 hours, then add 1mol of dimethyl phosphate, continue to react for 5 hours, after the reaction, use physical methods to remove the inorganic components and water in the system, and distill off the solvent in the system , to obtain the ester compound C 1mol of the above structure with an ester equivalent weight of 160 g / eq.

[0101] The obtained compound C is characterized by proton nuclear magnetic resonance spectrum, and the results are as follows:

[0102] 1 H NMR (CDCl 3 ,500MHz):δ5.1(m,1H,-POC H CH 2 OP-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com