Biodegradable fluorescent mesoporous silica composite nanosphere and preparation method thereof

A technology of mesoporous silica and biodegradation, which is applied in the field of fluorescent nanometers, can solve the problems of MSN degradation, reduction, and limitation of biological application range, etc., and achieve the effect of mild reaction conditions and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

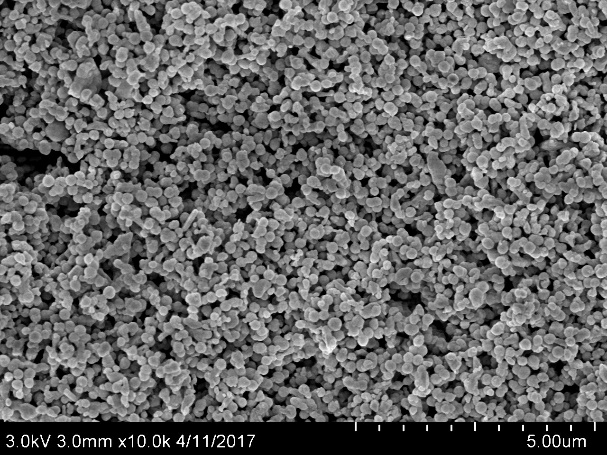

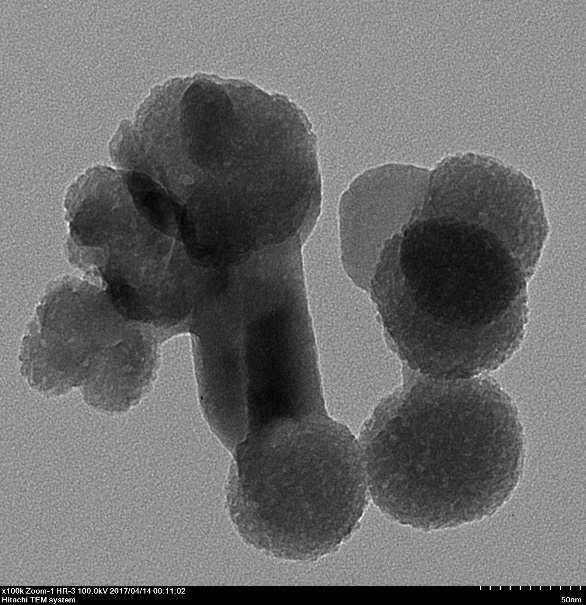

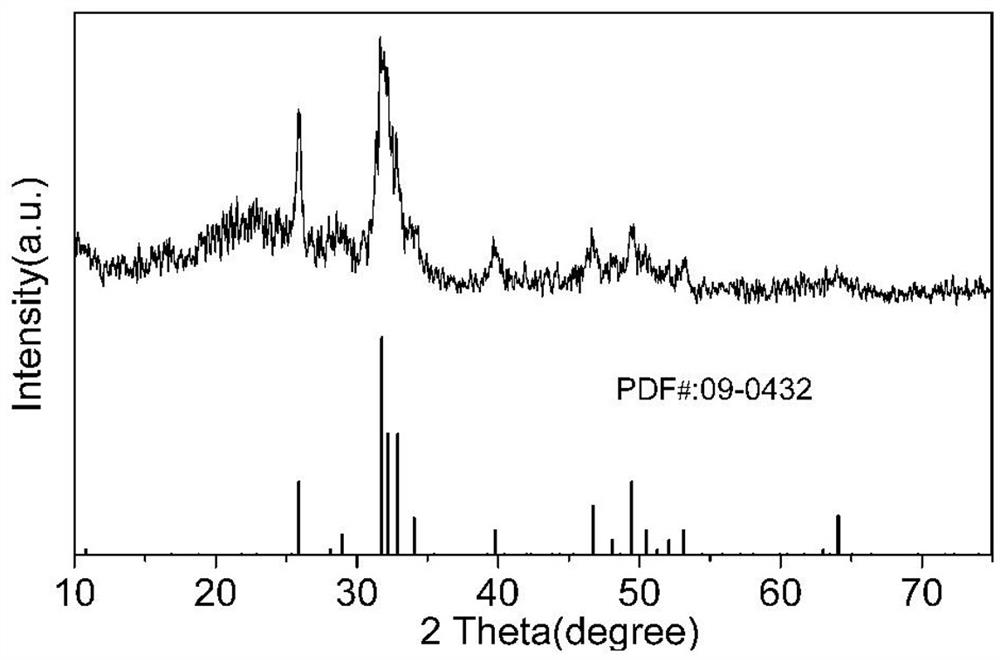

Image

Examples

Embodiment 1

[0028] A preparation method of biodegradable fluorescent mesoporous silica composite nanospheres, comprising the following steps,

[0029] (1) Take 5×10 -4 mol~10×10 -4 mol cetyltrimethylammonium p-toluenesulfonate (CTAT) was added to the three-necked flask, and then 20-80 mL deionized water and 5×10 -4 mol~6.7×10 -3 mol triethanolamine (TEA), magnetically stirred at 70-90°C for 40-60 min to prepare template micelles in the reaction system;

[0030] (2) Add 5×10 -4 mol~1.6×10 -3 molHPO 4 2- Ionic solution, magnetic stirring at 70-90°C for 30-50 minutes. Then, under mechanical stirring at 600-1000 rpm, add 6×10 -3 mol~1.2×10 -2 mol silicate, after stirring for 3-10 min, quickly add 7.5×10 -4 mol~2.56×10 -3 mol Ca 2+ ionic solution and 5 x 10 -6 mol~5×10 -5 mol of Eu 3+ Ionic solution, 70-90 °C water bath, continue to stir for 4-6 h, cool to room temperature and centrifuge to obtain the precipitate, wash the precipitate with deionized water and absolute ethanol fo...

Embodiment 2

[0033] (1) Add 0.342 g of cetyltrimethylammonium p-toluenesulfonate (CTAT) into a 100 mL three-necked bottle, then add 50 mL of deionized water, and ultrasonically disperse for 5 min to obtain a transparent and uniform mixed solution. Add 0.2 g of triethanolamine (TEA) to the mixture, seal it, and magnetically stir it in a water bath at 80°C for 40 min to prepare template micelles in the reaction system;

[0034] (2) Then add 0.32 g Na to the step-up solution 2 HPO 4 •12H2 O, continue stirring for 30 min. Under mechanical stirring at a speed of 1000 rpm, 2.0 mL tetraethyl orthosilicate (TEOS) was added dropwise at a rate of 1 drop / s, and the addition was completed within 5 minutes, and the stirring was continued for 3 minutes. Then quickly add 0.15 g of anhydrous CaCl 2 and a volume of 50 μL of EuCl at a concentration of 0.5 mol / L 3 The solution was stirred in a water bath at 80 °C for 4 h, cooled to room temperature, and centrifuged at a speed of 5000 rpm to obtain a prec...

Embodiment 3

[0037] A preparation method of biodegradable fluorescent mesoporous silica composite nanospheres, comprising the following steps,

[0038] (1) Add 0.360 g of cetyltrimethylammonium p-toluenesulfonate (CTAT) into a three-neck flask, then add 80 mL of deionized water and 1.0 g of triethanolamine (TEA), and stir magnetically at 90°C for 60 min to prepare Obtain the template agent micelle in the reaction system;

[0039] (2) Add 0.50g Na to the template micelles in the reaction system prepared in step (1) 2 HPO 4 •12H 2 O, magnetic stirring at 70-90°C for 30-50 minutes. Then, under mechanical stirring at 1000 rpm, 3.0 mL of methyl orthosilicate was added dropwise at a rate of 2 drops / second, and after stirring for 3 to 10 min, 0.2 g of Ca(NO 3 ) 2 powder and a volume of 100 μL of EuCl at a concentration of 0.5 mol / L 3 The solution was continuously stirred in a water bath at 90°C for 5 h, cooled to room temperature and then centrifuged, the precipitate was washed twice with d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com