Environment-friendly baked brick

A sintered brick and environmental protection technology, applied in building components, buildings, building structures, etc., can solve the problems of mildew on the wall, irritating odor, injuries to sintered brick production workers and installation workers, etc., and achieve good antibacterial and sterilization. effect, reduce the high radioactivity of the material, and prevent the problem of bacterial growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

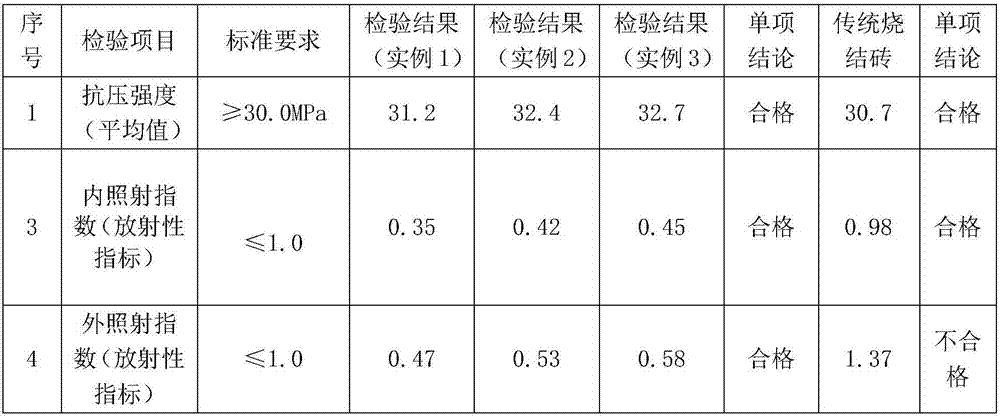

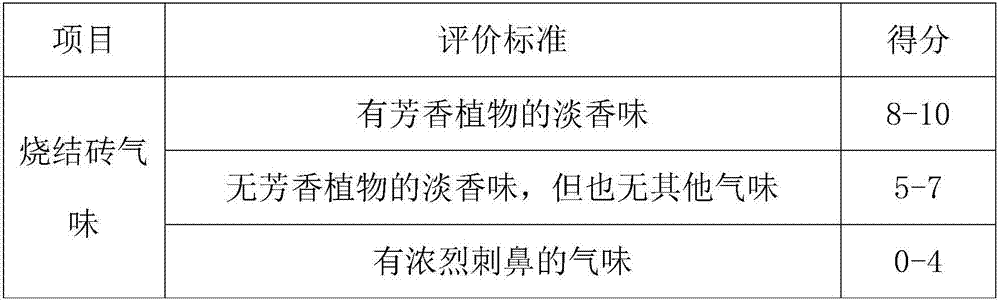

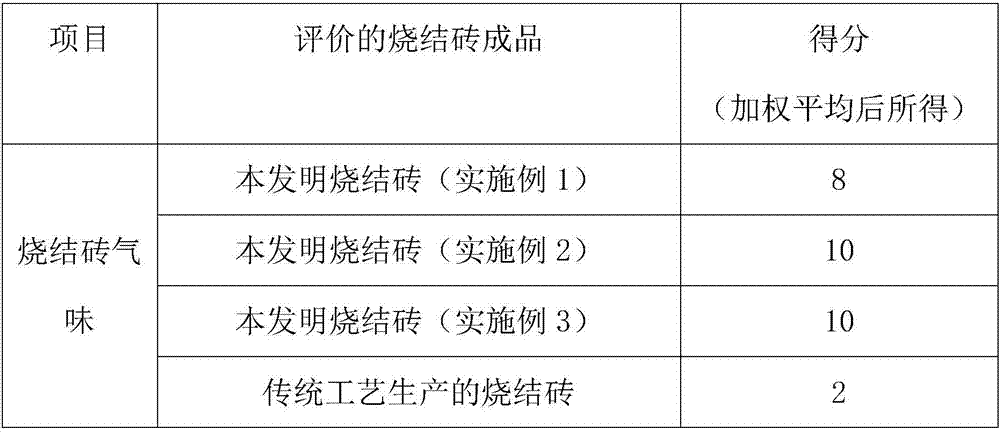

Embodiment 1

[0041]An environmentally friendly sintered brick is made by the following steps:

[0042] (1) Put 5Kg of eucalyptus oil and 5Kg of tea tree oil into a high-speed mixer and stir for 6 to 10 minutes to obtain product A;

[0043] (2) Put 10Kg of bamboo charcoal into product A for 20-40 minutes in an oil bath, and the bamboo charcoal after the oil bath is filtered to be product B;

[0044] (3) Put 30Kg lead-zinc slag, 20Kg desulfurization ash and product B into a high-speed mixer and stir for 15-20 minutes to obtain product C;

[0045] (4) Add 20Kg of water to product C and stir evenly to obtain adobe raw material, which is pressed into adobe under a pressure of 12 to 14MPa through a hydraulic press in a hydraulic extrusion molding mode;

[0046] (5) sending the adobe into a drying chamber to dry until the water content of the adobe is 5% to 6%;

[0047] (6) Send the dried adobe into the kiln and sinter at a sintering temperature of 850°C to 1000°C for 4h to 8h to obtain the pro...

Embodiment 2

[0049] An environmentally friendly sintered brick is made by the following steps:

[0050] (1) Put 7Kg of eucalyptus oil and 7Kg of tea tree oil into a high-speed mixer and stir for 6 to 10 minutes to obtain product A;

[0051] (2) Put 12Kg of bamboo charcoal into product A for 20-40 minutes in an oil bath, and the bamboo charcoal after the oil bath is filtered to be product B;

[0052] (3) Put 32Kg lead-zinc slag, 25Kg desulfurization ash and product B into a high-speed mixer and stir for 15-20 minutes to obtain product C;

[0053] (4) Add 25Kg of water to product C and stir evenly to obtain adobe raw material, which is pressed into adobe under a pressure of 12 to 14MPa through a hydraulic press in a hydraulic extrusion molding mode;

[0054] (5) sending the adobe into a drying chamber to dry until the water content of the adobe is 5% to 6%;

[0055] (6) Send the dried adobe into the kiln and sinter at a sintering temperature of 850°C to 1000°C for 4h to 8h to obtain the pr...

Embodiment 3

[0057] An environmentally friendly sintered brick is made by the following steps:

[0058] (1) Put 8Kg of eucalyptus oil and 8Kg of tea tree oil into a high-speed mixer and stir for 6 to 10 minutes to obtain product A;

[0059] (2) Put 15Kg of bamboo charcoal into product A for 20-40 minutes in an oil bath, and the bamboo charcoal after the oil bath is filtered to be product B;

[0060] (3) Put 35Kg lead-zinc slag, 30Kg desulfurization ash and product B into a high-speed mixer and stir for 15-20 minutes to obtain product C;

[0061] (4) Add 30Kg of water to product C and stir evenly to obtain adobe raw material, which is pressed into adobe by hydraulic extrusion molding under a pressure of 12-14MPa through a hydraulic press;

[0062] (5) sending the adobe into a drying chamber to dry until the water content of the adobe is 5% to 6%;

[0063] (6) Send the dried adobe into the kiln and sinter at a sintering temperature of 850°C to 1000°C for 4h to 8h to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com