Glass deinking agent

A deinking agent and glass technology, applied in the direction of chemical paint/ink remover, coating, etc., can solve the problems of complicated deinking operation, complex deinking agent system, and increased deinking cost, so as to improve deinking Yield rate, beneficial to deinking and corrosion inhibition, and the effect of reducing deep scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

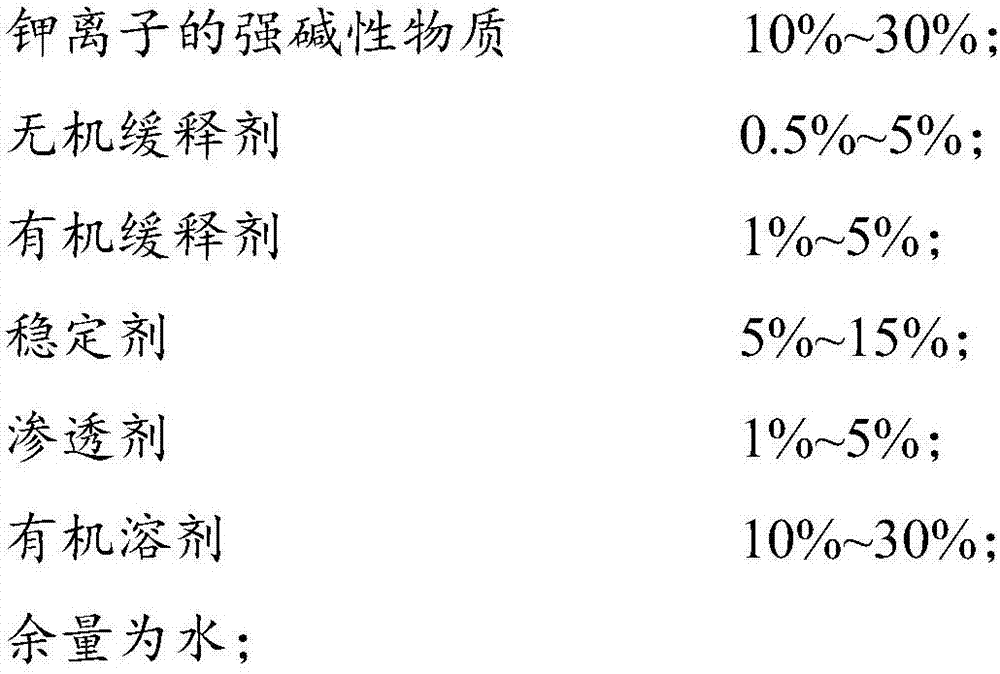

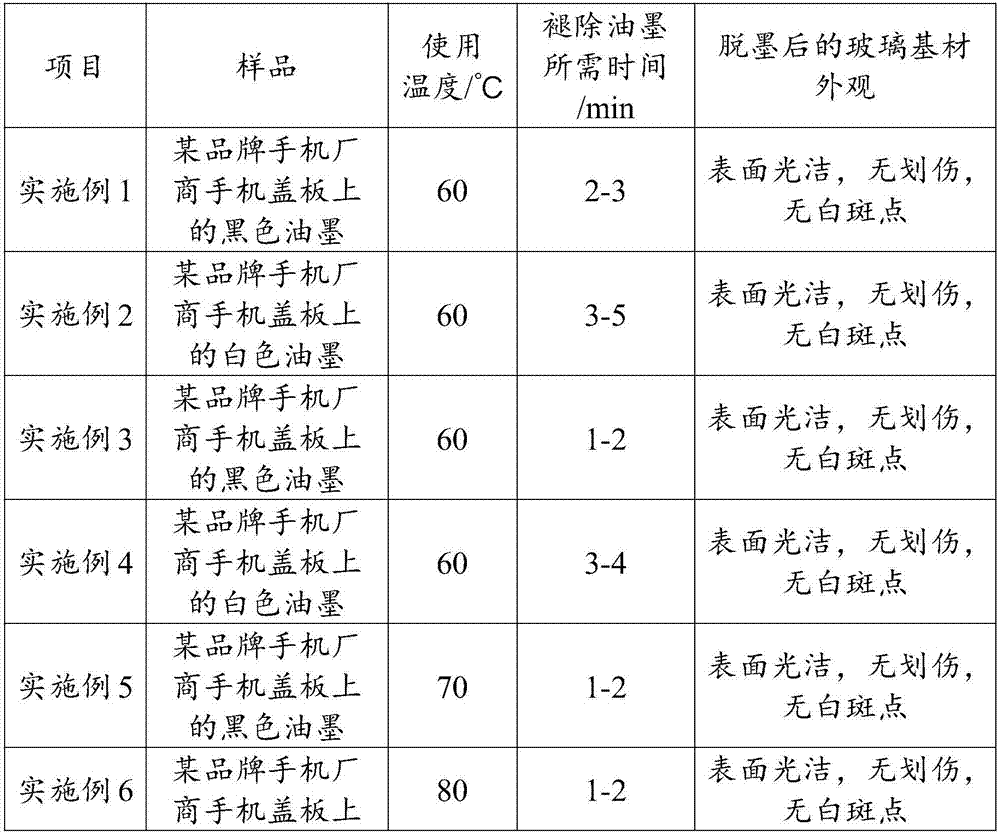

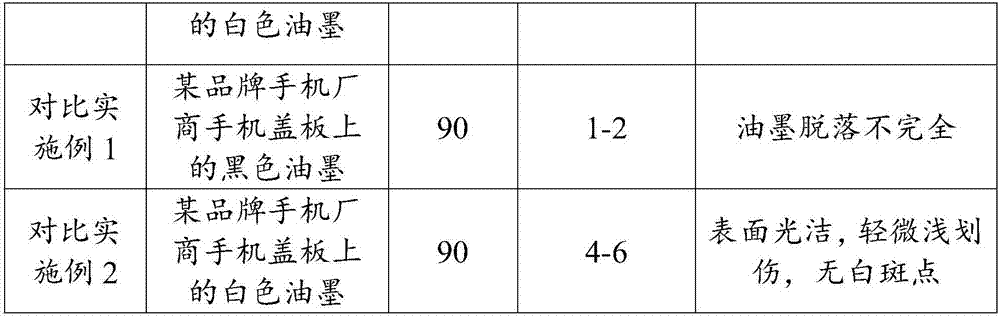

[0028] The invention provides a glass deinking agent, comprising the following components and their mass percentages: 10% potassium hydroxide, 1% zinc acetate, 1% undecanedibasic acid, 5% diglycolamine, 1% alkyl Glycoside SL-4, 10% ethanol, 72% water. Add the raw materials of each component into the container, and stir evenly at room temperature.

Embodiment 2

[0030] The invention provides a glass deinking agent, which comprises the following components and their mass percentages: 15% potassium hydroxide, 3% zinc acetate, 2% behenic acid, 10% diglycolamine, 3.5% lauryl Alcohol ether phosphate, 15% ethylene glycol ether, 51.5% water. Add the raw materials of each component into the container, and stir evenly at room temperature.

Embodiment 3

[0032] The invention provides a glass deinking agent, which comprises the following components and their mass percentages: 30% potassium hydroxide, 5% zinc acetate, 5% behenic acid, 15% triethanolamine, 5% alkyl alcohol Amidophosphate, 30% Isohexanediol, 10% Water. Add the raw materials of each component into the container, and stir evenly at room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com