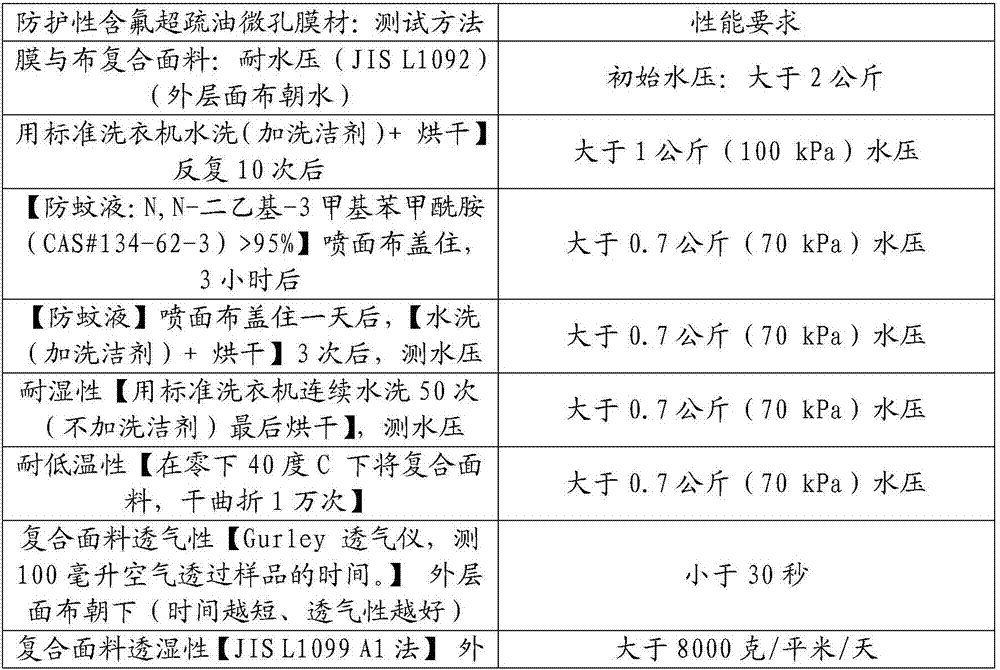

Fluorine containing mixed material for fluorine containing super oil repellent microporous membrane

A technology of microporous film and compound material, applied in application, household appliances, other household appliances, etc., can solve the problems of low oil resistance, no air permeability, low tensile strength of the membrane, etc., and achieve high waterproofness and avoid deflagration and explosion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1 is the preparation of high molecular weight polytetrafluoroethylene copolymerized dispersion resin

[0046] In a horizontal autoclave with an internal volume of about 1000 liters, first add 500 liters of deionized water, 20 kg of high-purity paraffin (melting point 50 ° C ~ 85 ° C), and 180 grams of perfluorooctanoic acid ammonium, and vacuumize the inside of the autoclave Exhaust oxygen (up to oxygen content99.999% in the still to make the inner pressure of the still reach about 22 kg. Then 300 grams of perfluoroethyl vinyl ether (C 2 f 5 -OCF=CF 2 ) as a comonomer, start to add in the kettle at a rate of 10 grams per minute, and add 0.8 gram of ammonium persulfate (dissolved in 500 milliliters of water in advance) as an initiator in the kettle to start the copolymerization reaction, and the temperature in the kettle is maintained at 80- 100°C, feed tetrafluoroethylene gas during the reaction to maintain the pressure in the kettle at about 20 kg. Conti...

Embodiment 2

[0047] The preparation of embodiment 2 polyurethane acrylate prepolymer

[0048] In a reaction kettle with an internal volume of about 200 liters, the jacket is first heated to 100°C, the kettle is vacuumed and nitrogen dehumidified, and 26.2 kg (containing about 200 moles of NCO isocyanate) 4,4'-dicyclohexylmethane is added Diisocyanate HMDI, start stirring, the temperature in the kettle rises to about 100°C, then add 60 kg (containing about 60 moles of -OH hydroxyl groups) of polypropylene glycol (molecular weight about 2000) to the kettle, react for about 90 minutes, add 18.2 Kg (containing about 140 mol-OH hydroxyl groups) hydroxyethyl methacrylate, the temperature in the kettle is maintained at about 100 ° C, and after about one hour of reaction, a polyurethane acrylate prepolymer with a viscous liquid is obtained. After cooling It is a liquid at 50°C, indicating that the melting point is lower than 50°C.

Embodiment 3

[0049] The preparation of the mixture of embodiment 3 polyurethane acrylate prepolymer and fluorine-free alkyl acrylate

[0050] (3A) When the weight ratio of polyurethane acrylate prepolymer to fluorine-free alkyl acrylate is 3:7: in a mixing tank with an internal volume of about 100 liters, add 15 kg of the polyurethane obtained in Example 2 under normal temperature and pressure Acrylate prepolymer, and then add 35 kg of isodecyl acrylate (CAS: 1330-61-6), continuously stir to form a homogeneous phase, stop stirring, and discharge the mixture to obtain polyurethane acrylate prepolymer and fluorine-free alkanes a mixture of acrylates.

[0051] (3B) When the weight ratio of polyurethane acrylate prepolymer to fluorine-free alkyl acrylate is 5:5: in a mixing tank with an internal volume of about 100 liters, add 25 kg of the polyurethane prepared in Example 2 under normal temperature and pressure Acrylate prepolymer, and then add 25 kg of isodecyl acrylate (CAS: 1330-61-6), con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

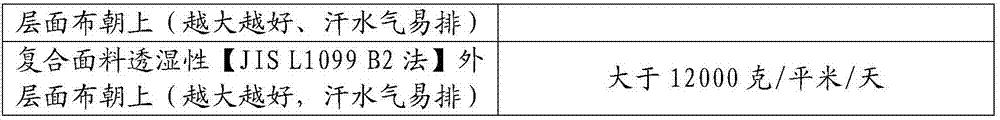

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com