Caron-coated stannous oxide compound and preparation method and application thereof

A stannous oxide and carbon coating technology, applied in electrochemical generators, electrical components, battery electrodes, etc., can solve problems such as large volume change and poor cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

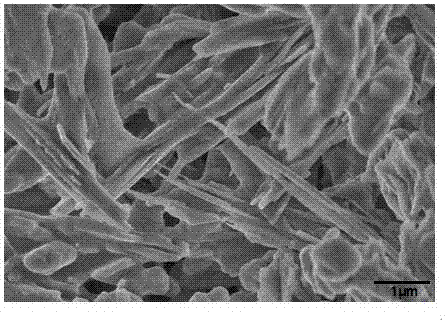

[0026] Example 1 Carbon-coated stannous oxide composite material

[0027] Dissolve 0.81g of Tris in 1L of water, stir, and prepare a buffer solution with pH=7.5; measure 20mL of the prepared buffer solution with a graduated cylinder, add 30mg of stannous oxide (SnO) into the buffer solution, Stir for 30 minutes to obtain a black turbid solution; add 10 mg of dopamine, and continue stirring for 47 hours; wash the obtained black liquid with distilled water and ethanol several times, centrifuge, and then put it in a vacuum oven at 60°C for drying; finally dry the black The material was calcined at 400°C for 2 hours under a nitrogen atmosphere, and the heating rate of the calcination was 4°C / min to obtain a carbon-coated stannous oxide (tin monoxide) composite material.

Embodiment 2

[0028] Example 2 Carbon-coated stannous oxide composite material

[0029] Dissolve 1.6g of Tris in 1L of water, stir, and prepare a buffer solution with pH=9.5; measure 80mL of the prepared buffer solution with a graduated cylinder, add 30mg of stannous oxide (SnO) into the buffer solution, Stir for 25 minutes to obtain a black turbid solution; add 20 mg of dopamine, and continue stirring for 47 hours; wash the obtained black liquid with distilled water and ethanol several times, centrifuge, and then put it in a vacuum oven at 60 ° C for drying; finally dry the black The material was calcined at 450°C for 2 hours under a nitrogen atmosphere, and the heating rate of the calcination was 4°C / min to obtain a carbon-coated stannous oxide (tin monoxide) composite material.

Embodiment 3

[0030] Example 3 Carbon-coated stannous oxide composite material

[0031] Dissolve 1.21g of Tris in 1L of water, stir, and prepare a buffer solution with pH=8.5; measure 50mL of the prepared buffer solution with a graduated cylinder, add 30mg of stannous oxide (SnO) to the buffer solution, Stir for 30 minutes to obtain a black turbid solution; add 30 mg of dopamine, and continue to stir for 48 hours; wash the obtained black liquid with distilled water and ethanol several times, centrifuge, and then put it in a vacuum oven at 60 ° C for drying; finally dry the black The material was calcined at 400°C for 2 hours under a nitrogen atmosphere, and the heating rate of the calcination was 4°C / min to obtain a carbon-coated stannous oxide (tin monoxide) composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com