Preparation method and application for cadmium sulfide/bismuth oxyiodide heterojunction photo-catalyst

A photocatalyst and heterojunction technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of high-efficiency and rapid removal of organic pollutants, low photocatalyst activity, and synthetic methods Complexity and other issues, to achieve the effects of reduced energy consumption, simple preparation process, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

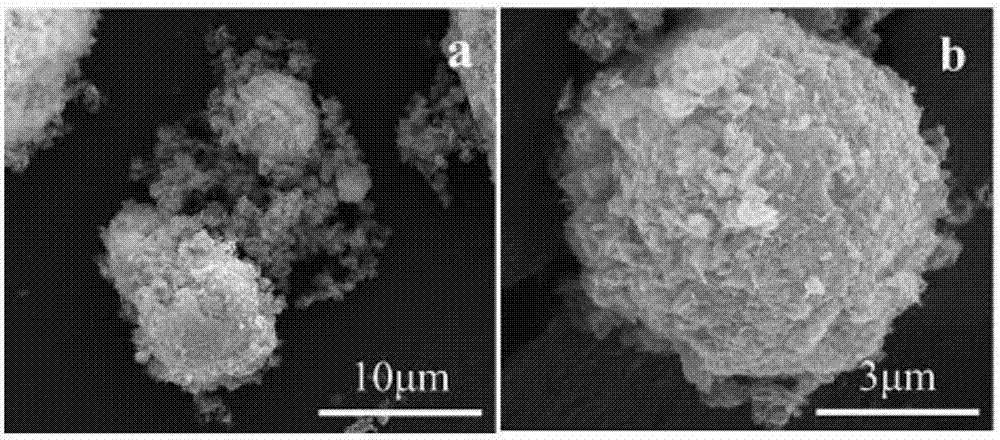

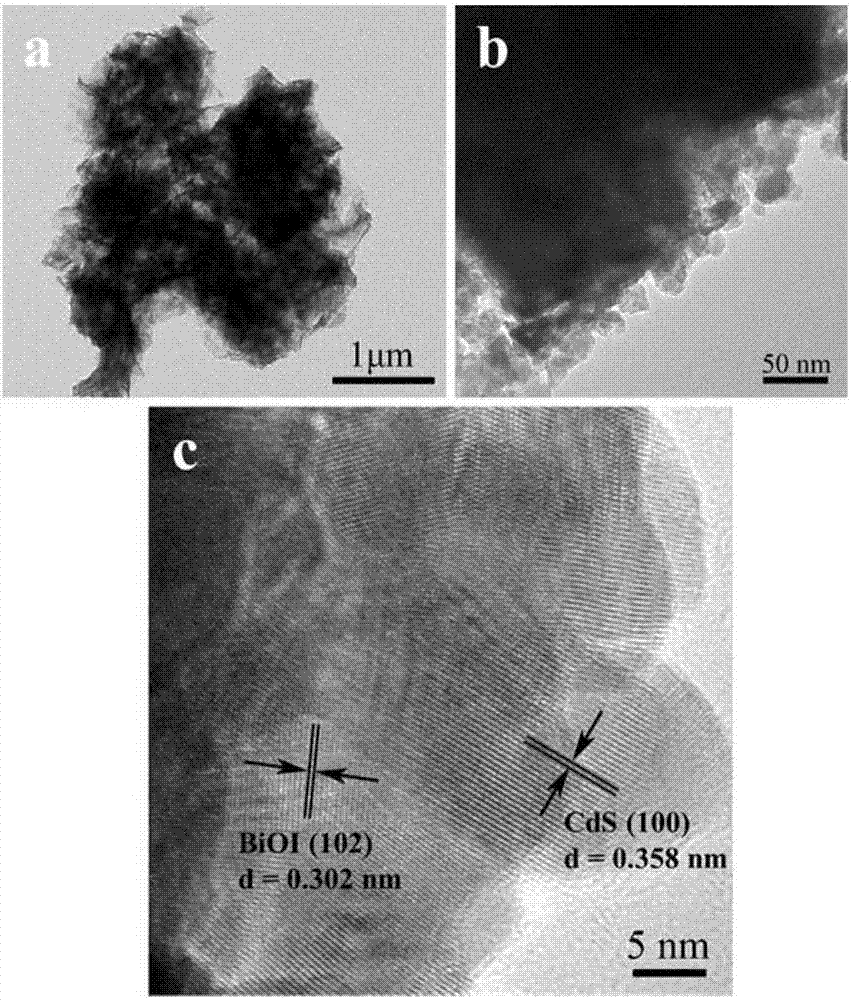

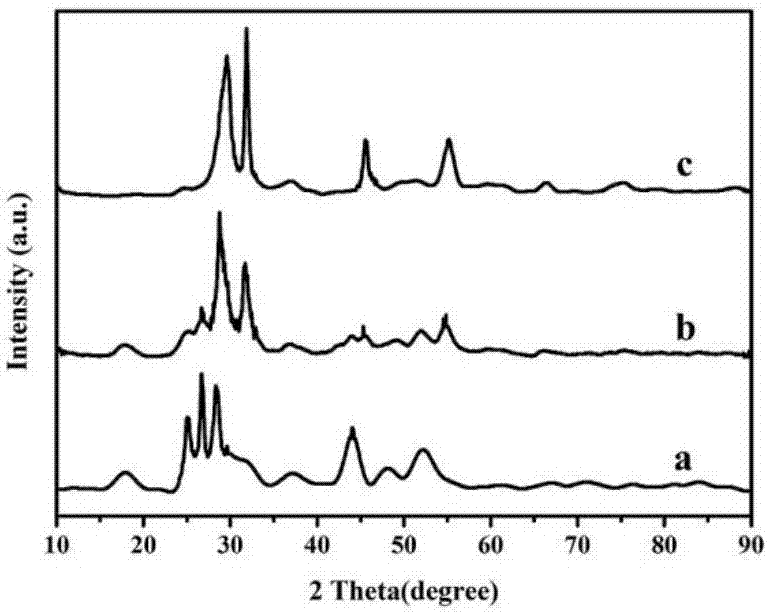

Embodiment 1

[0048] (1) Dissolve 2 mmol of bismuth salt in 35 ml of ethylene glycol and stir magnetically for 30 min at room temperature;

[0049] (2) Dissolve 2 mmol of iodine source in 35 ml of ethylene glycol, stir magnetically at room temperature for 10 min, then add dropwise to the above solution, and continue stirring for 1 h;

[0050] (3) Transfer the above mixed solution to a reaction kettle, and put it in an oven at 120°C for 12 h to obtain an orange-red solid;

[0051] (4) The orange-red solid was separated by centrifugation, washed three times with deionized water and absolute ethanol respectively, and dried in an oven at 60°C;

[0052] (5) Take out the dried solid and grind it with an agate mortar to obtain dry BiOI powder;

[0053] (6) Dissolve 2 mmol cadmium salt in 200 ml deionized water and stir at room temperature for 15 min;

[0054] (7) Add the prepared BiOI powder to the above solution and continue stirring for 15 min;

[0055] (8) Add 0.75 mmol buffer salt to the ab...

Embodiment 2

[0062] (1) Dissolve 2 mmol of bismuth salt in 35 ml of ethylene glycol and stir magnetically for 30 min at room temperature;

[0063] (2) Dissolve 2 mmol of iodine source in 35 ml of ethylene glycol, stir magnetically at room temperature for 10 min, then add dropwise to the above solution, and continue stirring for 1 h;

[0064] (3) Transfer the above mixed solution to a reaction kettle, and put it in an oven at 140°C for 8 h to obtain an orange-red solid;

[0065] (4) The orange-red solid was separated by centrifugation, washed three times with deionized water and absolute ethanol respectively, and dried in an oven at 60°C;

[0066] (5) Take out the dried solid and grind it with an agate mortar to obtain dry BiOI powder;

[0067] (6) Dissolve 2 mmol cadmium salt in 200 ml deionized water and stir at room temperature for 15 min;

[0068] (7) Add the prepared BiOI powder to the above solution and continue stirring for 15 min;

[0069] (8) Add 0.75 mmol buffer salt to the abo...

Embodiment 3

[0076] (1) Dissolve 3 mmol of bismuth salt in 35 ml of ethylene glycol and stir magnetically for 30 min at room temperature;

[0077] (2) Dissolve 3 mmol of iodine source in 35 ml of ethylene glycol, stir magnetically at room temperature for 10 min, then add dropwise to the above solution, and continue stirring for 1 h;

[0078] (3) Transfer the above mixed solution to a reaction kettle, put it in an oven at 140°C for 12 h, and obtain an orange-red solid;

[0079] (4) The orange-red solid was separated by centrifugation, washed three times with deionized water and absolute ethanol respectively, and dried in an oven at 60°C;

[0080] (5) Take out the dried solid and grind it with an agate mortar to obtain dry BiOI powder;

[0081] (6) Dissolve 1 mmol cadmium salt in 200 ml deionized water and stir at room temperature for 15 min;

[0082] (7) Add the prepared BiOI powder to the above solution and continue stirring for 15 min;

[0083] (8) Add 0.75 mmol buffer salt to the abov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com