Catalytic material for degrading indoor formaldehyde in room temperature and preparation method thereof

A catalytic material and formaldehyde technology, applied in chemical instruments and methods, separation methods, molecular sieve catalysts, etc., can solve the problems of high energy consumption, high cost, and short life of adsorbents, and achieve simple preparation process, convenient operation, and low price Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

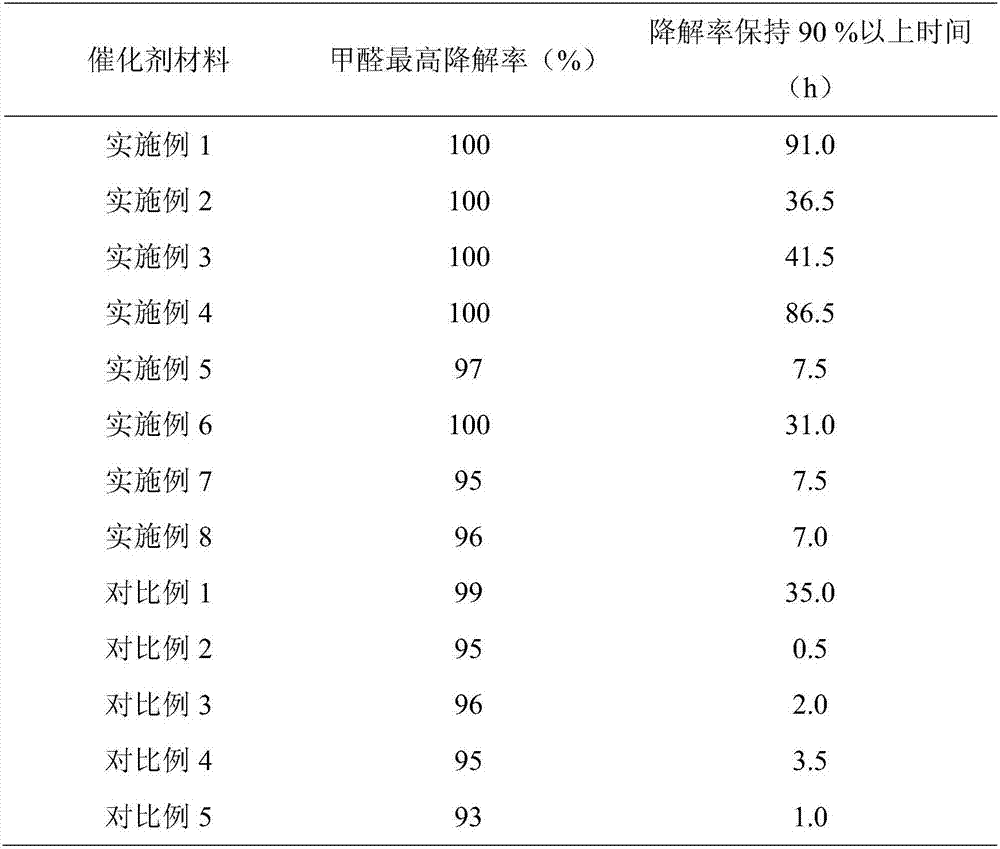

Examples

Embodiment 1

[0029] A catalytic material for degrading indoor formaldehyde at room temperature, with a simple active component MnO 2 as a catalytic material. Concrete preparation steps are as follows:

[0030] (1) Take by weighing 5.0g manganese sulfate, be dissolved in 100ml deionized water, stir 1h and make manganese sulfate solution;

[0031] (2) Take by weighing 5.0g sodium hydroxide, be dissolved in 100ml deionized water, stir for 0.5h to obtain sodium hydroxide solution;

[0032] (3) under stirring condition, the acid solution of step (1) and the alkali solution of step (2) are added dropwise in the mixer simultaneously, wherein acid solution is titrated by 5ml / min flow velocity, and alkali solution is titrated by 8ml / min flow velocity, control pH=8~9, continue to stir for 12 hours after the titration is completed to obtain a mixture solution;

[0033] (4) The mixture solution was filtered, washed, and dried in an oven at 110° C. for 12 hours to obtain a catalytic material for deg...

Embodiment 2

[0035] A catalytic material for degrading indoor formaldehyde at room temperature, with a simple active component MnO 2 as a catalytic material. Concrete preparation steps are as follows:

[0036] (1) Take by weighing 5.0g manganese sulfate, be dissolved in 100ml deionized water, stir 1h and make manganese sulfate solution;

[0037] (2) Measure 10ml of concentrated ammonia water, add deionized water and dilute to 50ml to prepare ammonia water dilute solution;

[0038] (3) under stirring condition, the acid solution of step (1) and the alkali solution of step (2) are added dropwise in the mixer simultaneously, wherein acid solution is titrated by 5ml / min flow velocity, and alkali solution is titrated by 10ml / min flow velocity, control pH=8~9, continue to stir for 14 hours after the titration is completed to obtain a mixture solution;

[0039] (4) The mixture solution was filtered, washed, and dried in an oven at 110° C. for 3 hours to obtain a catalytic material for degradin...

Embodiment 3

[0041] A catalytic material for degrading indoor formaldehyde at room temperature, with a simple active component MnO 2 as a catalytic material. Concrete preparation steps are as follows:

[0042] (1) Take by weighing 5.0g manganese sulfate, be dissolved in 100ml deionized water, stir 1h and make manganese sulfate solution;

[0043](2) Take by weighing 28.5g of ammonium carbonate, measure 22.5ml of concentrated ammonia water, add deionized water to be configured into an alkaline solution of 100mlpH=10;

[0044] (3) under stirring condition, the acid solution of step (1) and the alkali solution of step (2) are added dropwise in the mixer simultaneously, wherein acid solution is titrated by 5ml / min flow velocity, and alkali solution is titrated by 12ml / min flow velocity, control pH=8~9, continue to stir for 12 hours after the titration is completed to obtain a mixture solution;

[0045] (4) The mixture solution was filtered, washed, and dried in an oven at 110° C. for 5 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com